Real-time monitoring device of concrete capillary water absorption rate under load

A technology of real-time monitoring and capillary water absorption, which is applied in the direction of weighing by removing certain components, can solve the problems of continuous monitoring of the water absorption of the test piece, etc., and achieve the effect of uniform stress and avoiding stress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

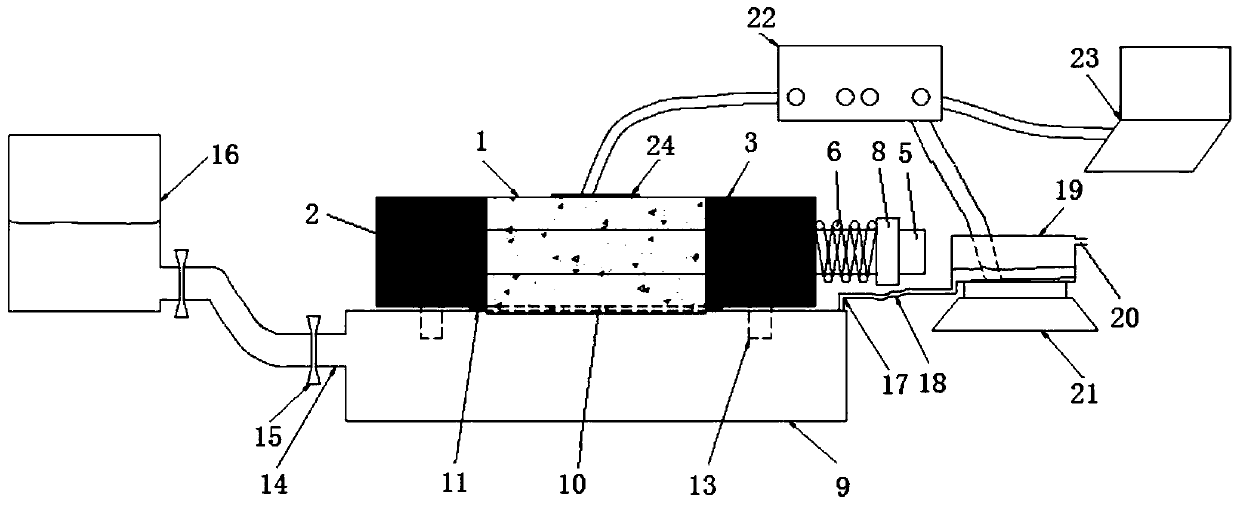

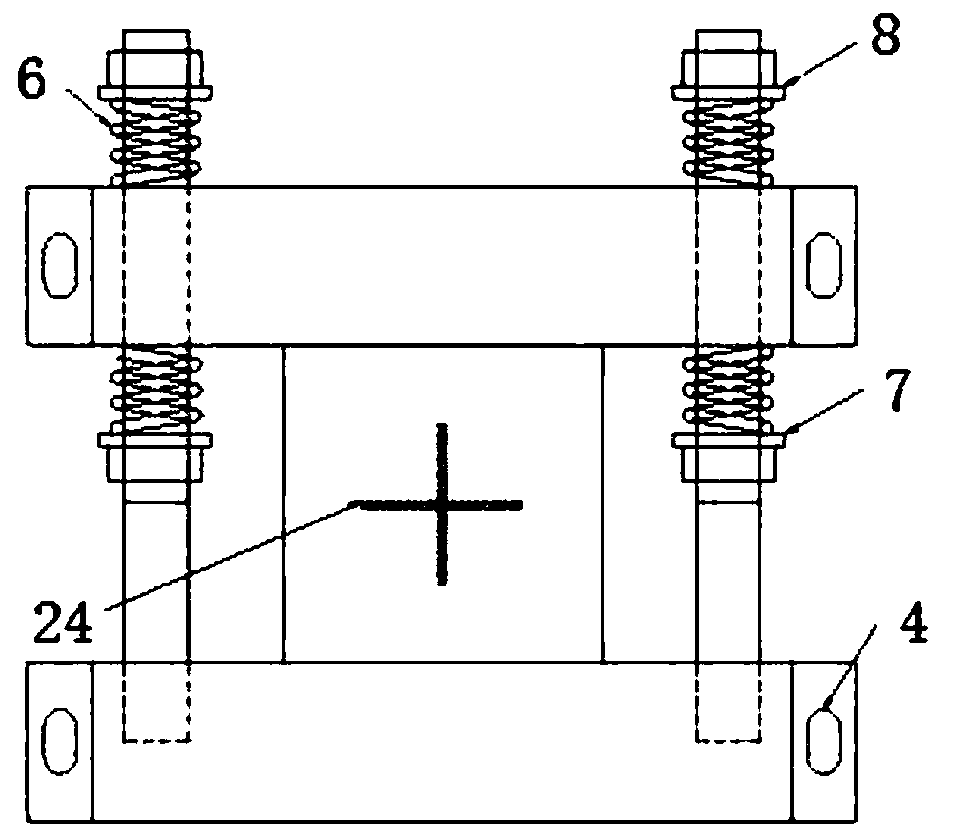

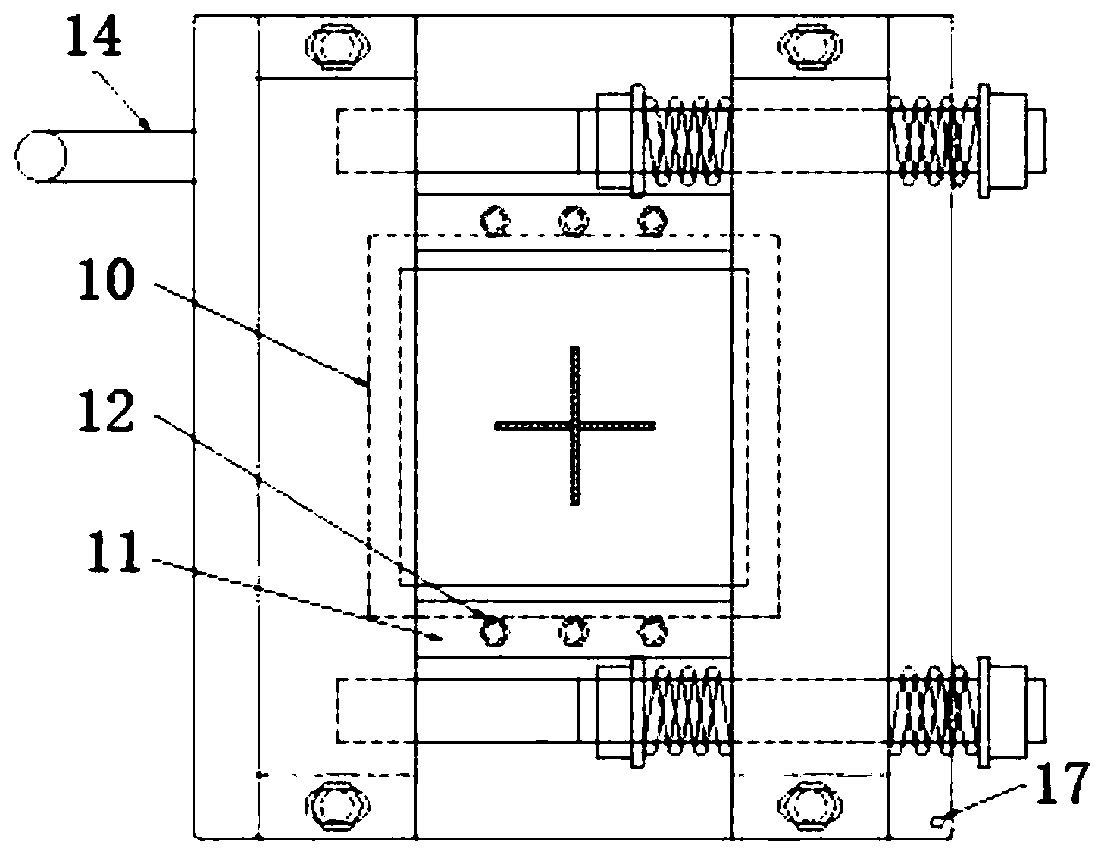

[0019] The main structure of the real-time monitoring device for capillary water absorption of concrete under sustained load in this embodiment includes a concrete specimen 1, a left steel plate 2, a right steel plate 3, a reserved hole 4, a threaded rod 5, a spring 6, a pull nut 7, and a pressure nut 8. Suction box 9, sealing ring 10, cover plate 11, No. 1 high-strength bolt 12, No. 2 high-strength bolt 13, water injection pipe 14, water injection valve 15, water supply tank 16, water outlet pipe 17, silicone hose 18, water storage tank 19 , air pressure balance hole 20, mass sensor 21, multi-channel data collector 22, computer 23 and strain gauge 24; the left elevation of the concrete specimen 1 of rectangular parallelepiped structure is connected with the left steel plate 2 of rectangular plate-shaped structure by bonding, and the concrete The right elevation of specimen 1 is adhesively connected to the right steel plate 3 with a rectangular plate structure, the two ends of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com