Prestressed carbon fibre cloth stretching bed seat

A carbon fiber cloth and tension pedestal technology, which is used in bridge maintenance, bridge erection/assembly, bridge reinforcement, etc., can solve the problems of material waste, the mechanical properties of carbon fiber cloth with high strength and tensile strength are not fully exerted, etc. Small stress loss and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

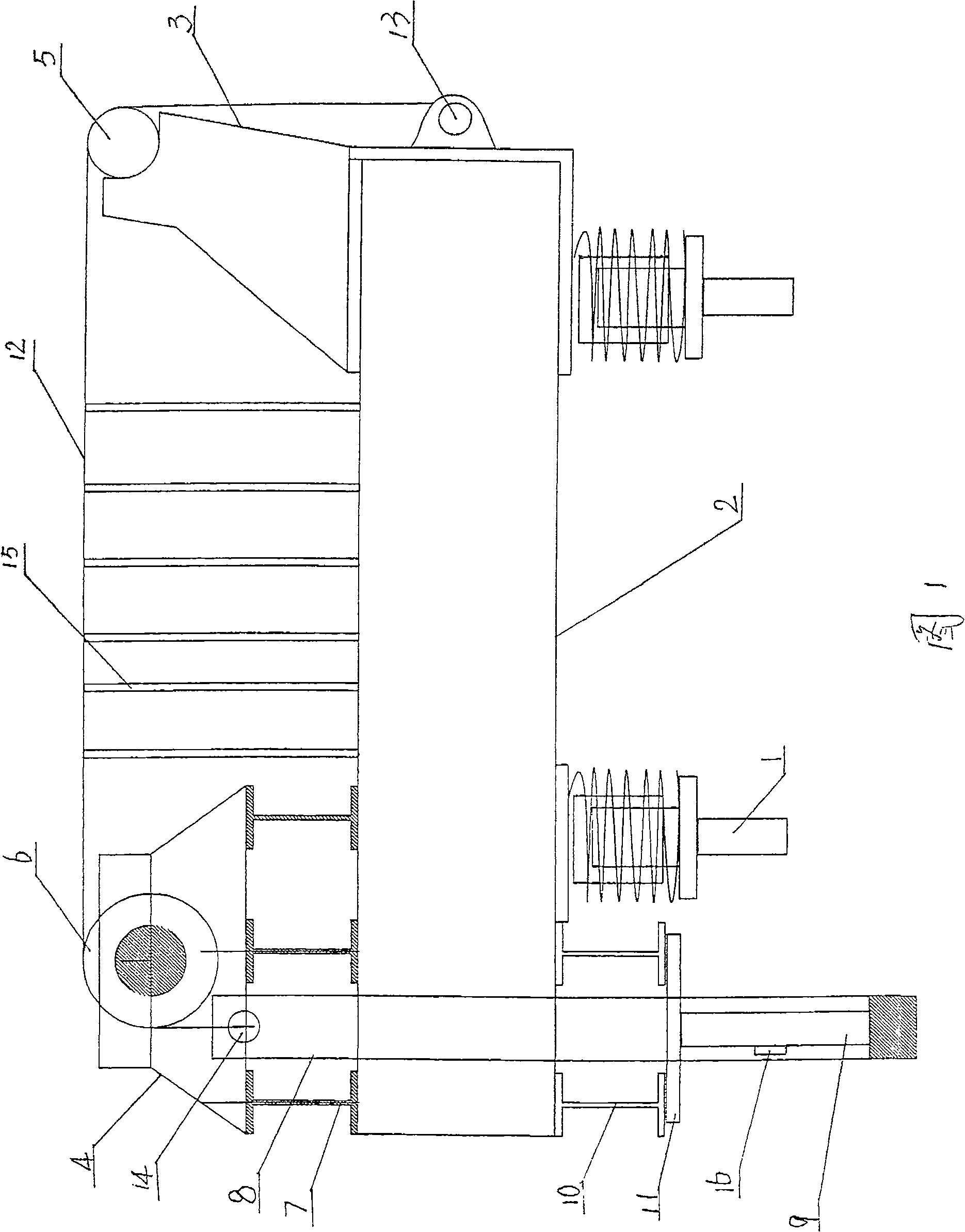

[0012] As shown in Figure 1, the pedestal consists of a lifting cylinder 1, a bridge beam 2, an anchor 3, a tension member 4, a first roller 5, a second roller 6, a connecting member 7, a tensioning fixture 8, a tensioning Oil cylinder 9, crossbeam 10, force plate 11 are composed of, a set of lifting oil cylinder 1 is installed under the bridge beam 2, an anchor piece 3 with a first roller shaft 5 is installed above one end of the bridge beam 2, and the bridge beam The tension member 4 with the second roller shaft 6 is installed above the other end of 2 through a set of connecting parts 7, and at least two beams 10 are connected under the bridge beam 2 on the same side of the tension member 4, and the bottom of the two beams 10 is connected The force plate 11 and the base of a group of tensioning cylinders 9 are placed on the bottom end surface of the frame type tensioning fixture 8, and the tensioning fixture 8 is suspended and fixed on one end of the carbon fiber cloth 12.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com