Energy feedback shock absorber with damping stiffness changing along with road condition

A shock absorber and stiffness technology, used in shock absorbers, gas-liquid shock absorbers, shock absorbers, etc., can solve the problems of suspension damage energy, reduce suspension service life, loss, etc., to protect from damage , the effect of reducing frequency and amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

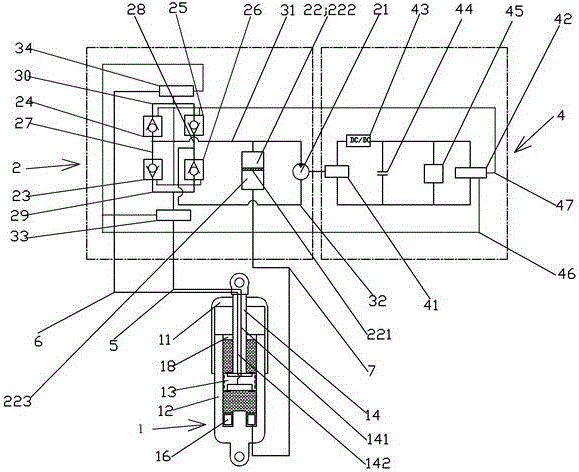

[0026] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present embodiment is composed of an energy-feeding shock absorber 1 , a hydraulic device 2 , a power generation device 4 , a first high-pressure oil pipe 5 , a second high-pressure oil pipe 6 and a high-pressure air pipe 7 .

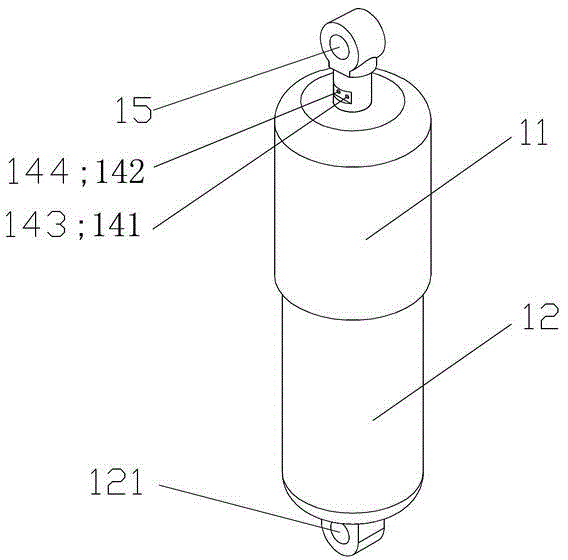

[0027] The energy-feeding shock absorber 1 is composed of a dust cover 11, a cylinder 12, a combined piston 13, a piston rod 14, a single clevis 15, an air bag 16, an air bag shield 17 and an end cover 18. The dust cover 11 There is a round hole 111; the cylinder 12 is provided with a single earring 121 and a round hole 122;

[0028] The combined piston 13 is composed of a first disc 131, a second disc 132, a third disc 133, a fourth disc 134, two positioning pins 135, six bolts 136 and six nuts 137, The first disc 131 is provided with a first circular hole 1311, a second circular hole 1312, two third circular holes 1313, a first positioning pin hole 1314, a second positioning pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com