Atmospheric temperature difference circulation airflow generating device

A technology for circulating airflow and generating devices, which is applied in the direction of mechanisms, machines/engines, and mechanical equipment that generate mechanical power. It can solve the problems of reducing the life of the turbine, limiting the flow rate of the airflow, and low efficiency, so as to enhance the heat absorption capacity and improve the efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

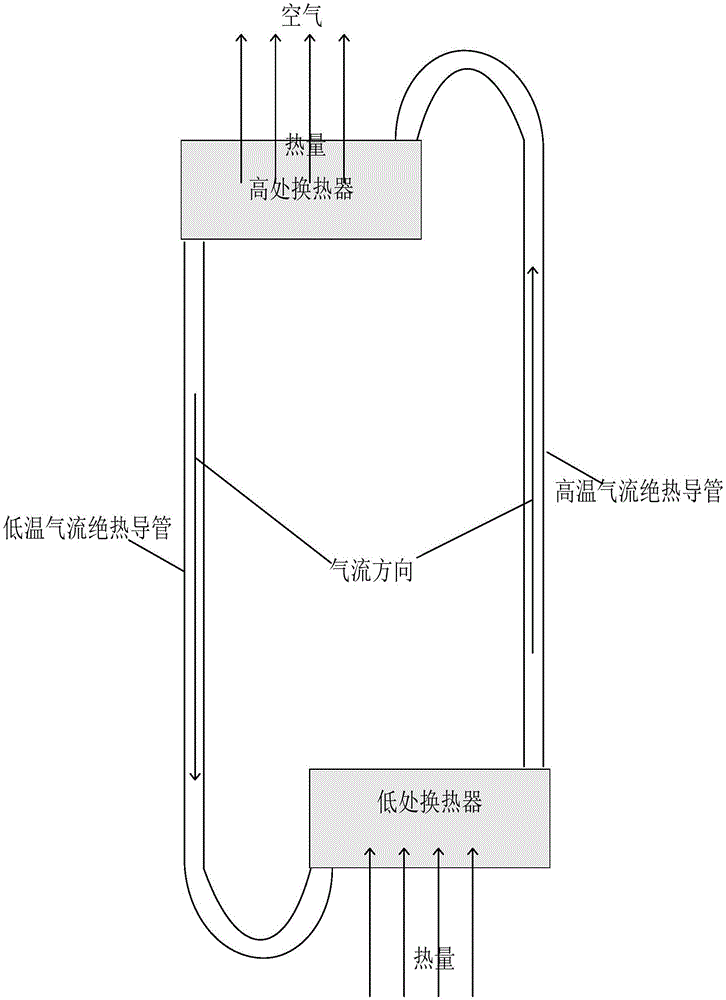

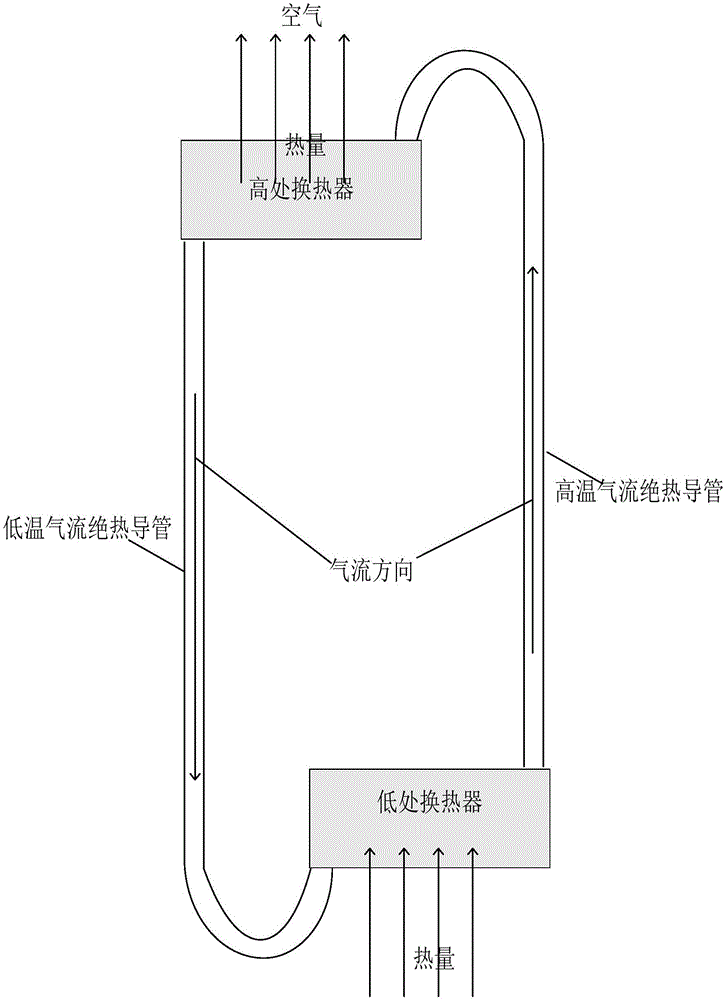

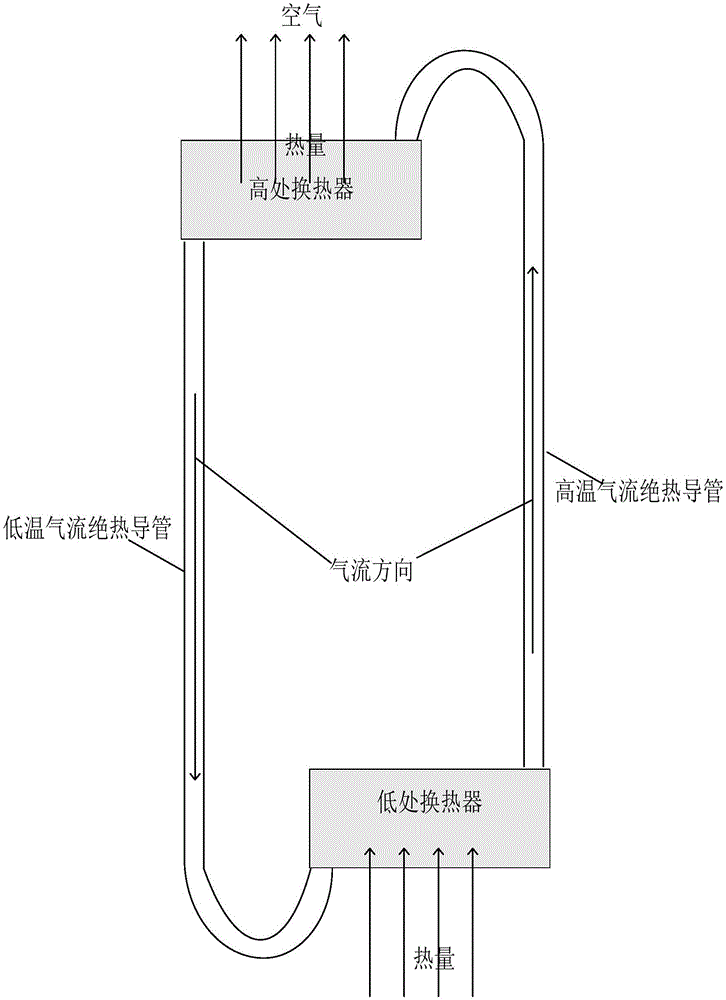

[0021] as attached figure 1 As shown, the apparatus includes an upper heat exchanger and a lower heat exchanger, and a downdraft insulated conduit and an updraft insulated conduit connecting the upper heat exchanger and the lower heat exchanger together. The cross-section of the downdraft adiabatic conduit is four times that of the updraft adiabatic conduit. The lower end of the downflow heat insulation pipe is slightly lower than the lower heat exchanger, and is connected with the lower heat exchanger through the reducer. The updraft insulated conduit is connected to the upper heat exchanger through a diffuser. A part of the lower end of the downflow heat insulation conduit is lower than the lower heat exchanger, which is beneficial to control the direction of the airflow. In the updraft insulated duct, a turbine power generation system is installed.

[0022] In this example, the gas in the device is a mixed gas of nitrogen and hydrogen, and the hydrogen gas fraction is 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com