A kind of self-propelled simple drilling and shearing machine and mining method for steeply inclined thin coal seam

A thin coal seam, self-propelled technology, used in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of complex process, low mining efficiency, and high technical requirements for equipment, achieve small volume and improve recovery rate. , the effect of high technical and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The specific implementations are as follows:

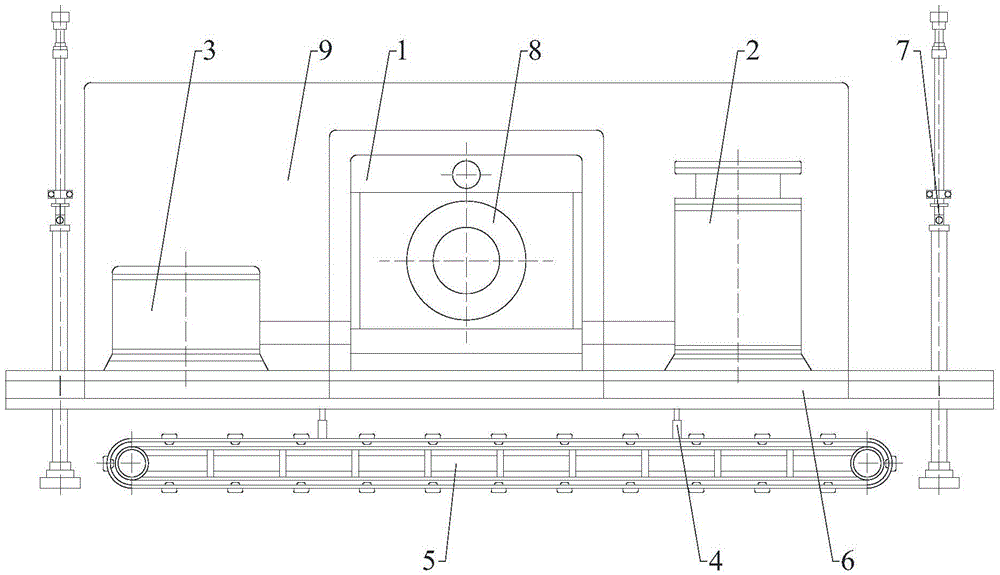

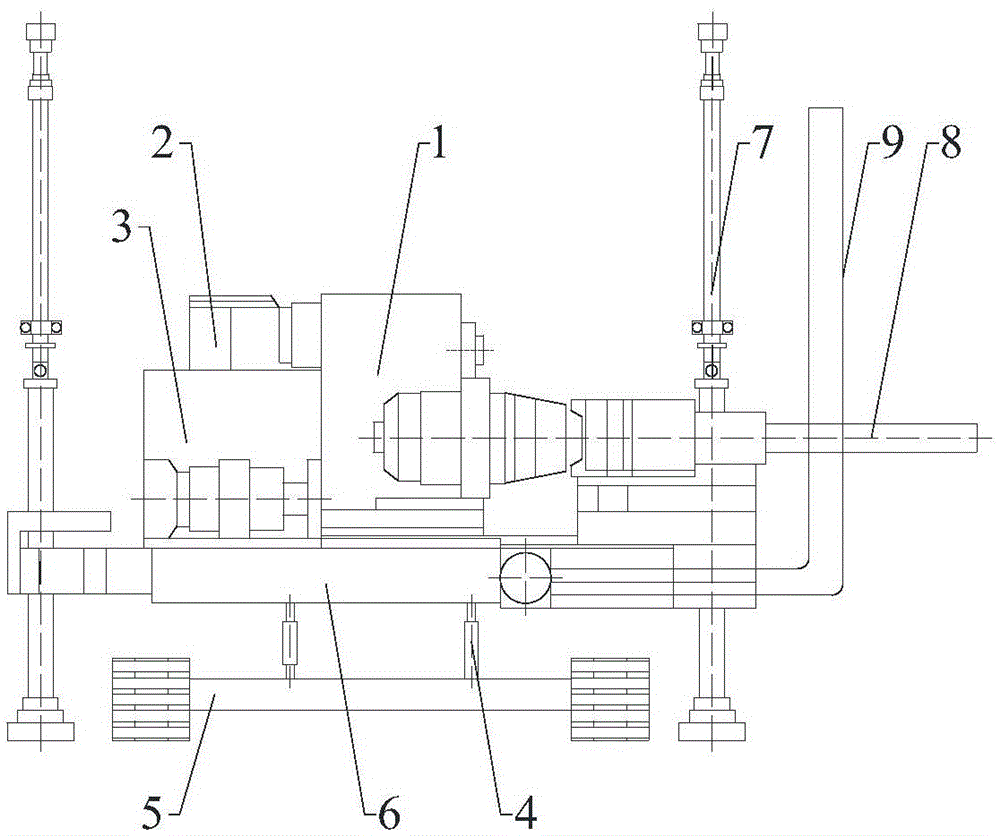

[0025] The coal mining machine includes: main engine 1, console 2, pump station 3, supporting hydraulic column 4, crawler chassis 5, base 6, stable hydraulic prop 7, drilling tool assembly 8 and coal baffle 9; main engine 1, operation The platform 2, the pump station 3 and the drilling tool assembly 8 are fixed on the base 6, and the stable hydraulic prop 7 is fixed on the four corners of the base 6. The base 6 is connected to the crawler chassis 5 through four supporting hydraulic columns 4; The plate 9 is connected to one side of the base, and the bit end of the drilling tool assembly 8 extends out of the coal baffle 9.

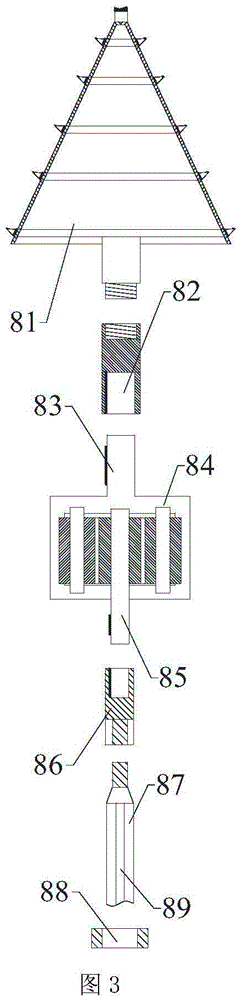

[0026] The drill tool assembly 8 consists of a drill bit 81, a drill bit joint 82, a high torque output shaft 83, a planetary reducer 84, a low torque input shaft 85, a drill pipe joint 86, a drill pipe 87, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com