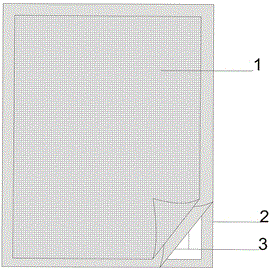

Nano window screen

A kind of screen window and nanotechnology, applied in the field of screen window, can solve the problems of large aperture and low blocking rate, and achieve the effect of small direct aperture and soft and warm direct light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

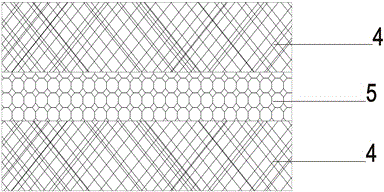

[0026] The PES solution was stretched under the action of an electric field to form nanofibers, which were deposited on a polypropylene nonwoven fabric pulled forward at a speed of 2 m / h.

[0027] Polypropylene non-woven fabric is mostly used for the filling layer of the filter element. It is characterized by high strength, good high temperature resistance, aging resistance, UV resistance, high elongation, good stability and air permeability, corrosion resistance, sound insulation, moth resistance, and no poison. PES has good heat resistance, hydrolysis resistance, creep resistance, excellent dimensional stability, and outstanding flame retardancy. It is used in the fields of electronic machinery, automobiles, medical equipment, coatings, etc. Bubble electrospinning method can prepare PES nanofiber membrane with large specific surface area, which can cover most of the pore diameter of polypropylene non-woven fabric, so that the pore diameter of non-woven fabric is reduced, and...

Embodiment 2

[0029] Titanium dioxide is added to the PES spinning solution. Titanium dioxide has the advantages of high photocatalytic activity, stability, non-toxicity, many times of reaction and easy acquisition, which makes it a very potential photocatalytic material at present. Therefore, the titanium dioxide is adhered to the polypropylene non-woven fabric and attached to the screen window by the method of bubble spinning, so that the air can be exchanged and the purpose of degrading VOC and other pollutants can be achieved, thereby achieving the process of being discharged outside. degrades it. At this time, the screen window mostly appears in the haze weather or in the newly decorated living room.

Embodiment 3

[0031] Add nano-activated carbon to the PES spinning solution. Activated carbon is a very small carbon particle with a large surface area, and there are smaller pores in the carbon particle-capillary. This kind of capillary has a strong adsorption capacity, and due to the large surface area of the carbon particles, it can fully contact with the gas (impurity).

[0032] Add activated carbon non-woven filter layer, which can absorb extremely small particles, so that the air containing harmful substances can be filtered through the filter material of the screen window before entering the room. This kind of filter screen window not only has the function of dust removal, but also has the characteristics of sterilization and deodorization. It can be widely used in the office environment to eliminate indoor odor and smoke; in the home environment, it can remove the human body odor in the bedroom, the bathroom odor, and the musty smell in the kitchen; A large amount of toxic and vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com