Modified asphalt cement particle, preparation method and applications thereof

A technology of cementing granules and modified asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of generating harmful gases, affecting the construction environment, and complicated manufacturing equipment, and achieves convenient transportation and use, reduces energy consumption, and is convenient transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

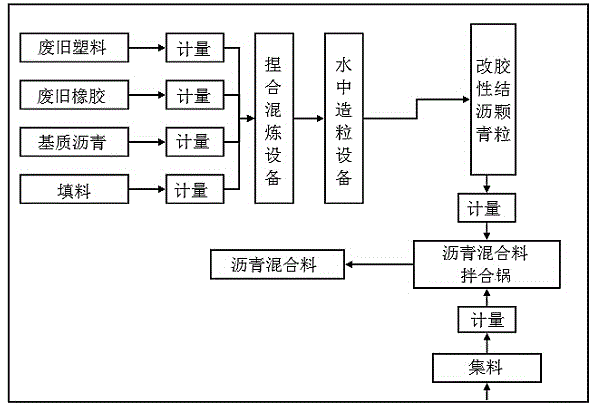

[0029] Such as figure 1 Shown is the preparation method of modified asphalt cementing particles in the present invention and the preparation process flow chart for preparing modified asphalt mixture, including the following process steps:

[0030] Step A, sending 5-20% waste plastics, 3-30% waste rubber, 60-90% matrix asphalt and 2-10% filler into the kneading and mixing equipment, kneading and extruding Melting the mixture, sending the obtained molten mixture into water granulation equipment, cooling and granulating to obtain modified asphalt cemented granules;

[0031] Step B. The modified asphalt cement particles obtained in step A are partially or completely replaced by ordinary asphalt, and put into the asphalt mixture mixing pot to directly prepare the modified asphalt mixture.

[0032] In the preparation process of the modified asphalt cement particles, the present invention adopts the method of kneader blending and water granulation, wherein the kneading and mixing eq...

Embodiment 1 to 5

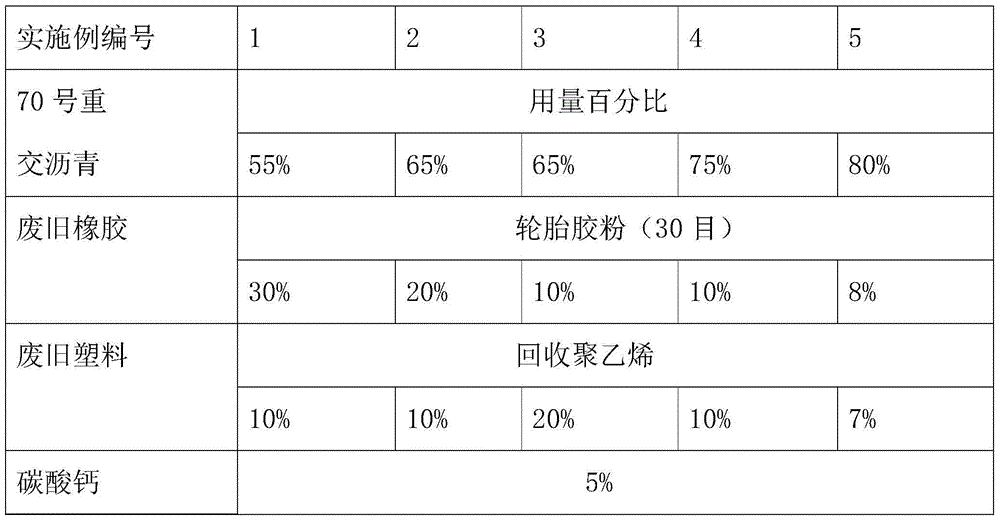

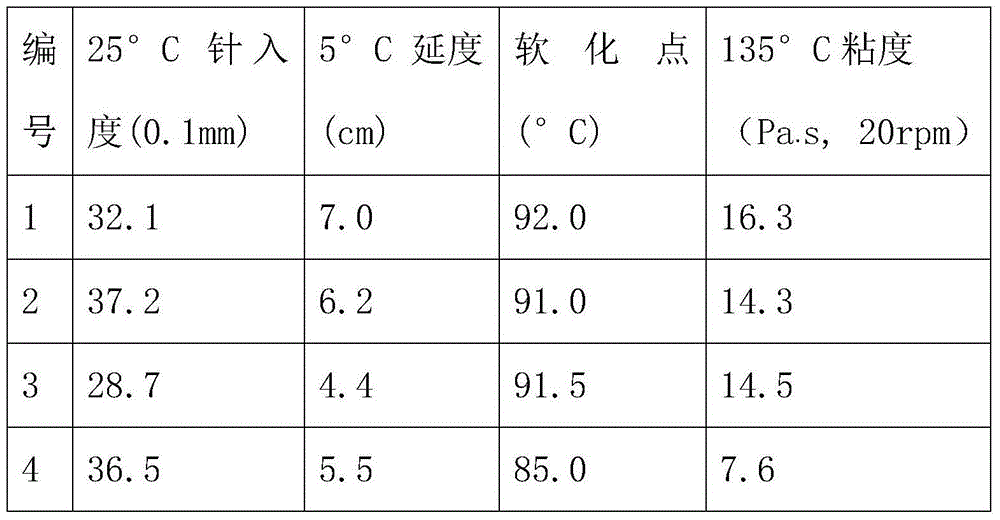

[0035] Table 1. Formulas of different modified asphalt cementing particles in Examples 1-5

[0036]

[0037] Note: The rotating speed is 30r / min, and the mixing time is 12min.

Embodiment 1

[0039] Step A: in parts by mass, mix 55kg of heavy-duty No. 70 asphalt, 30kg of tire rubber powder (30 mesh), and 10kg of waste polyethylene plastics in a 200L kneading internal mixer to prepare waste rubber and plastics asphalt cemented particles , the reaction temperature is 140°C, the rotation speed is 30r / min, and the time is 12min. After blending, through screw discharge, single-screw extrusion, and water pelletizer pelletization to obtain modified asphalt cemented pellets, the properties are shown in Table 2.

[0040] Step B: In terms of mass percentage, add 5% modified asphalt cementing particles to 95% asphalt mixture AC-13, mix indoors at 190°C for 3 minutes, and then prepare rubber-plastic modified asphalt mixture The specimens were cured at room temperature for 48 hours to test the performance of the mixture. The performance number of the prepared rubber-plastic modified asphalt mixture is 1, and the performance is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com