Low-volatile environment-friendly polyvinyl chloride (PVC) cable material and manufacturing process thereof

A polyvinyl chloride cable and polyvinyl chloride technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor quality of plasticizers, large smoke, shortened service life, etc., to improve aging fracture Tensile strain retention, prevention of secondary combustion and flame propagation, effects of good char formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

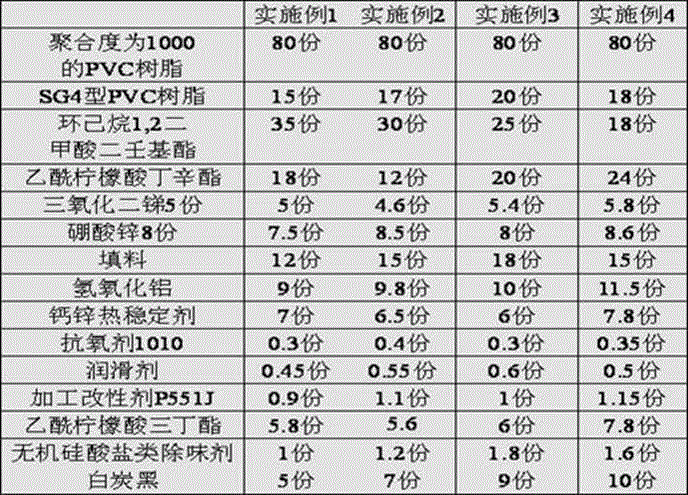

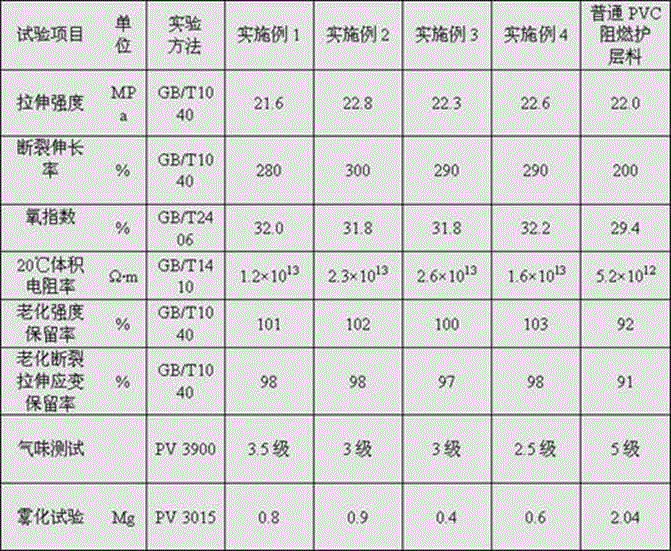

[0037] Embodiment 1~5: a kind of low volatility ring Conservation Polyvinyl chloride cable material, the high-flame-retardant and low-smoke PVC composite material for the booster grade cable is composed of the following components by weight, as table 1 Shown:

[0038] Table 1

[0039]

[0040] Above-mentioned lubricant is selected from at least one in stearic acid, polyethylene wax, calcium stearate, zinc stearate.

[0041] The inorganic silicate deodorant is purchased from Ningbo Boer Chemical, which is mainly an inorganic silicate material with a specific surface area of 400-600 m / g.

[0042] The above-mentioned filler is one or more mixtures of calcium carbonate, talcum powder and kaolin.

[0043] A low volatility ring Conservation The manufacturing process of polyvinyl chloride cable material comprises the following steps:

[0044] Step 1. Add 80 parts of PVC resin with a polymerization degree of 1000, 15-20 parts of SG4 type PVC resin, 10-40 parts of dinonyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com