A kind of method that methyl chloride prepares vinyl chloride monomer

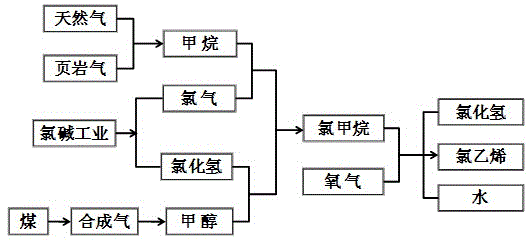

A technology of vinyl chloride monomer and methyl chloride, which is applied in the field of preparation of vinyl chloride monomer, can solve the problems of not giving examples, low selectivity of vinyl chloride, increased investment cost of reaction equipment, etc., and achieve the problem of mercury pollution, A wide range of resources to ease the effect of increasing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

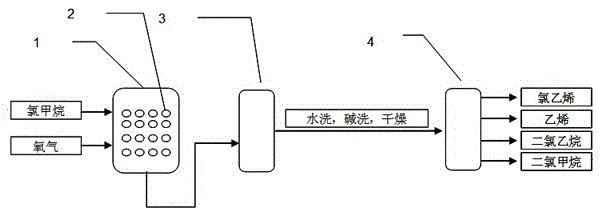

Method used

Image

Examples

Embodiment 1

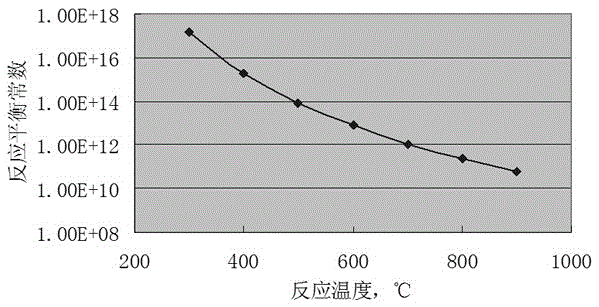

[0070] Mix methyl chloride and oxygen at a molar ratio of 1:0.1, and pass it into a reactor without catalyst added, the reaction temperature is 900°C, the reaction pressure is normal pressure, the reaction effluent is cooled to room temperature, washed with water and alkali to remove hydrogen chloride, condensed Remove water, pressurize, cool and separate to obtain liquid vinyl chloride. In terms of methyl chloride, the primary conversion rate is 10%, and the vinyl chloride selectivity is 8%.

Embodiment 2

[0072]Mix methyl chloride and oxygen at a molar ratio of 1:0.2, and pass it into a reactor without catalyst added, the reaction temperature is 800°C, the reaction pressure is normal pressure, the reaction effluent is cooled to room temperature, washed with water and alkali to remove hydrogen chloride, condensed Remove water, pressurize, cool and separate to obtain liquid vinyl chloride. In terms of methyl chloride, the primary conversion rate is 5%, and the selectivity of vinyl chloride is about 20%.

Embodiment 3

[0074] Mix methyl chloride and oxygen at a molar ratio of 1:0.5, and pass it into a reactor without catalyst added, the reaction temperature is 700°C, the reaction pressure is normal pressure, the reaction effluent is cooled to room temperature, washed with water and alkali to remove hydrogen chloride, condensed Remove water, pressurize, cool and separate to obtain liquid vinyl chloride. Based on methyl chloride, the primary conversion rate is 1%, and the selectivity of vinyl chloride is about 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com