HDPE(high-density polyethylene) membrane composited by high foaming of LDPE(Low-Density Polyethylene) and preparation method of HDPE membrane

A high-foaming and foaming agent technology, applied in the field of HDPE film, can solve the problems of low tensile strength, damaged products, easy to break, etc., and achieve the effect of improving mechanical strength, improving strength, softness and cushioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

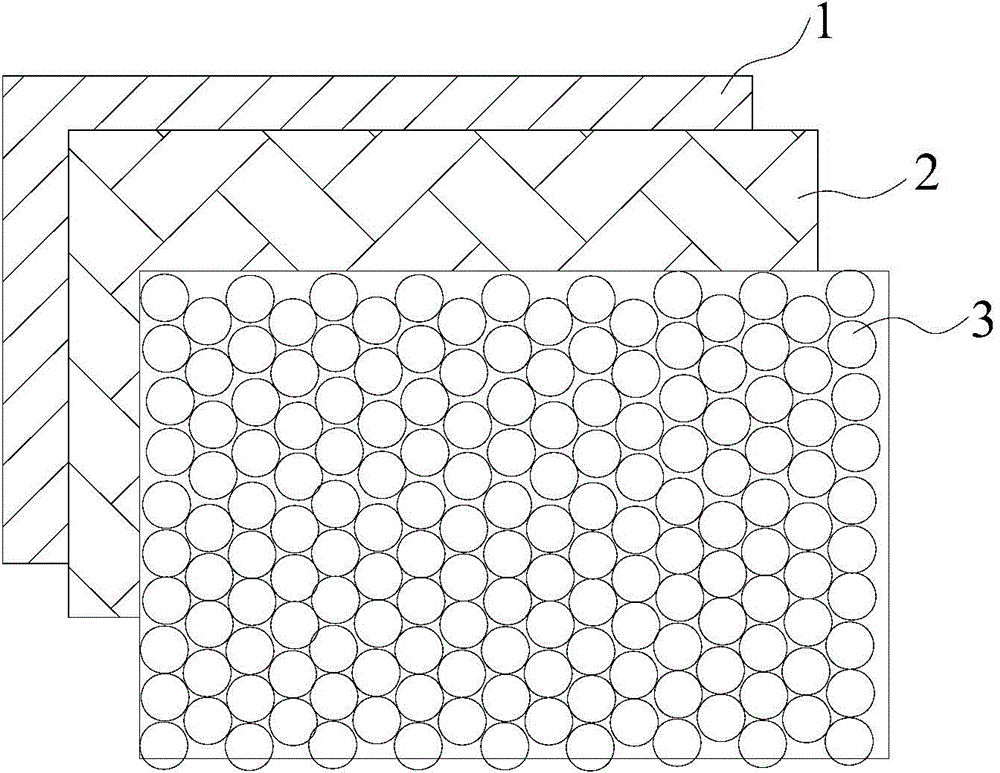

[0028] The LDPE high-foaming composite HDPE film of the present embodiment, such as figure 1 As shown, HDPE film 1 is included, wherein, the surface of HDPE film 1 is provided with a sheet layer 3 formed by high foaming of LDPE, and a PE adhesive layer 2 is provided between HDPE film 1 and sheet layer 3, that is, HDPE film 1 and sheet layer 3 are bonded together by PE adhesive layer 2.

[0029] Among them, in order to make the LDPE high-foaming composite HDPE film have good strength and shock resistance at the same time, the thickness ratio of the HDPE film 1, the PE adhesive layer 2 and the sheet layer 3 is 1:0.2:0.8, wherein the sheet layer 3 has a thickness of 1.0mm.

[0030] The PE adhesive layer used in this example, the PE film, is a film made by heating and melting PE plastic particles. The advantages of the PE film are: low cost, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com