A kind of tooling and casting method of casting nicralysi alloy target material

An alloy target and tooling technology, applied in metal material coating process, manufacturing tools, casting and molding equipment, etc., can solve the problems of material and energy waste, low production efficiency, etc., and achieve increased fluidity, high reliability, structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

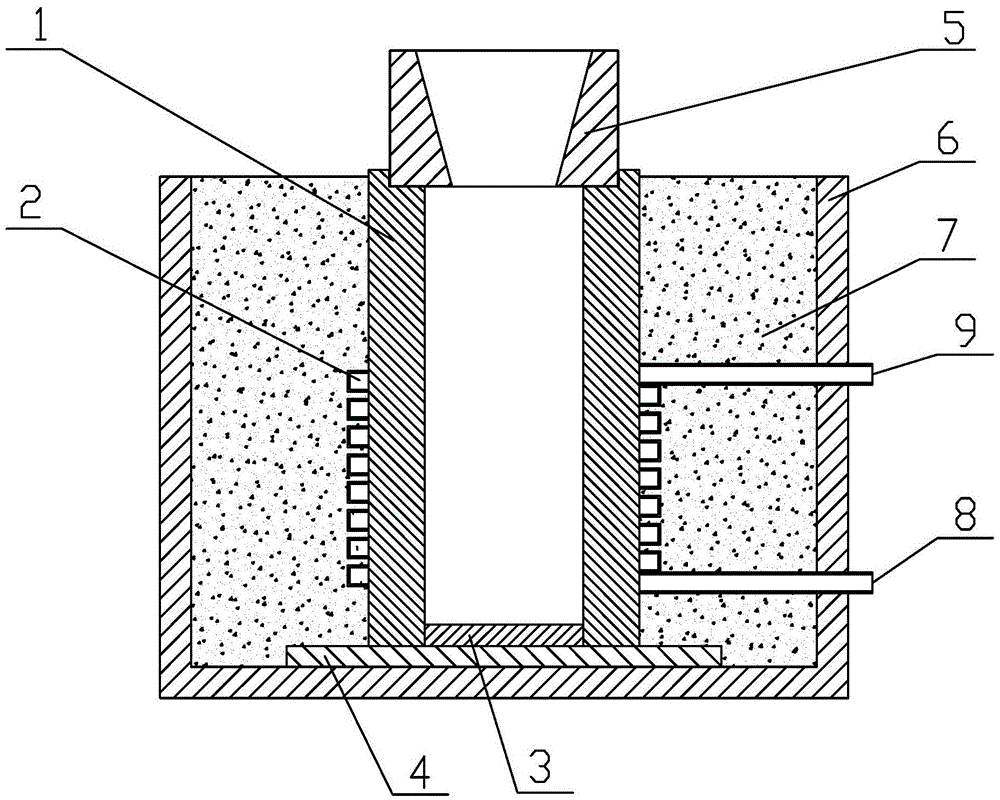

[0035] Such as figure 1 As shown, the tooling for casting a NiCrAlYSi alloy target in this embodiment includes a steel barrel 6 with an open upper end, a graphite backing plate 4 is arranged above the bottom of the steel barrel 6, and a graphite mold 1 is arranged above the graphite backing plate 4 , the upper end of the graphite mold 1 is provided with a thermal insulation riser 5 matched with the graphite mold 1, the outer wall of the graphite mold 1 is spirally wound with a cooling water pipe 2, and one end of the cooling water pipe 2 passes through the steel drum 6 as an inlet The water outlet 8, the other end of the cooling water pipe 2 passes through the steel drum 6 as the water outlet 9, the water inlet 8 is located below the water outlet 9, and the inside of the steel drum 6 and the outside of the graphite mold 1 are filled with alumina sand 7 , the height of the top of the alumina sand 7 does not exceed the upper end of the graphite mold 1.

[0036] Such as figure ...

Embodiment 2

[0043] This embodiment is the same as Example 1, except that the thickness of the graphite backing plate 4 is 15 mm, the diameter of the graphite backing plate 4 is 50 mm larger than the outer diameter of the graphite mold 1, and the height of the thermal insulation riser 5 is 70 mm. , the vertical distance between the bottom of the cooling water pipe 2 and the bottom of the graphite mold 1 is 50 mm, the top of the cooling water pipe 2 is located 40 mm above the center of the graphite mold 1, and the pitch of the cooling water pipe 2 is 5 mm. The outer side length of the section is 10 mm, the wall thickness is 1 mm, the inner diameter of the graphite mold 1 is 80 mm, the height is 300 mm, and the wall thickness is 15 mm.

Embodiment 3

[0045] This embodiment is the same as Example 1, except that the thickness of the graphite backing plate 4 is 12 mm, the diameter of the graphite backing plate 4 is 80 mm larger than the outer diameter of the graphite mold 1, and the height of the thermal insulation riser 5 is 60 mm. , the vertical distance between the bottom of the cooling water pipe 2 and the bottom of the graphite mold 1 is 40 mm, the top of the cooling water pipe 2 is located 50 mm above the center of the graphite mold 1, and the pitch of the cooling water pipe 2 is 3 mm. The outer side length of the section is 8 mm, the wall thickness is 0.8 mm, the inner diameter of the graphite mold 1 is 60 mm, the height is 250 mm, and the wall thickness is 12 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com