A kind of preparation method of photocatalyst for treating nitrophenol wastewater, a kind of treatment method of nitrophenol wastewater

A technology of nitrophenol and treatment methods, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of difficult catalytic degradation of macromolecules, hinder the diffusion of macromolecular products, etc., and achieve improved photocatalytic treatment Efficiency, increased pore volume, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

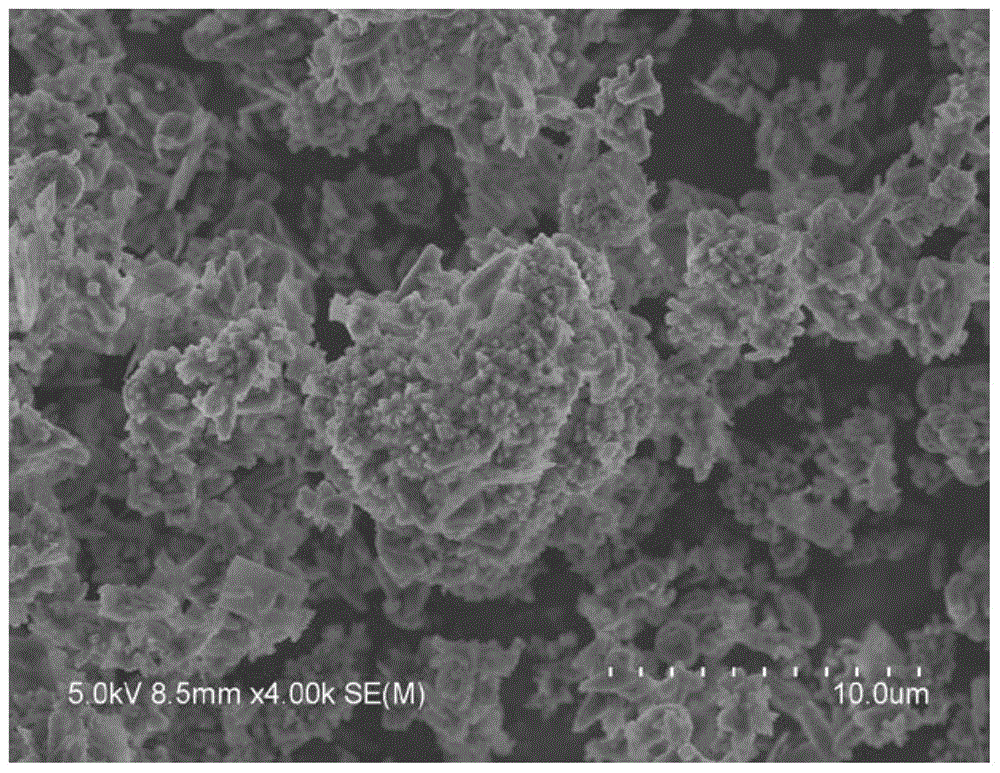

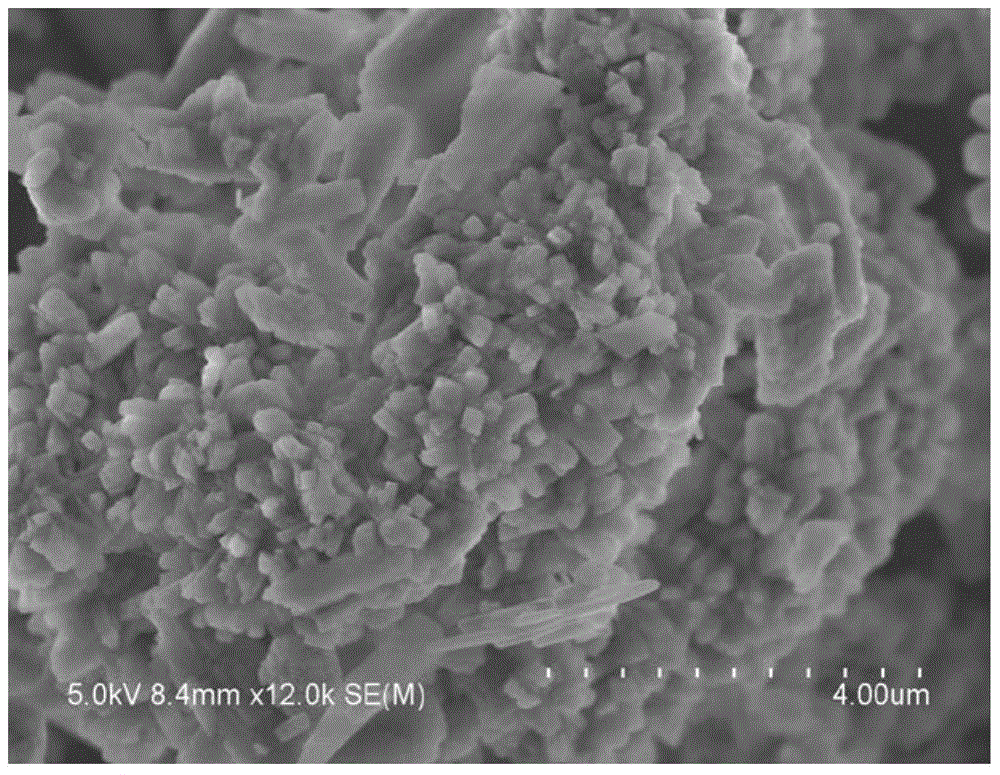

Image

Examples

Embodiment 1

[0049] A method for preparing a photocatalyst for treating nitrophenol wastewater, comprising the following steps:

[0050] a. Modified ZSM-5 zeolite;

[0051] Get 1g of commercial ZSM-5 zeolite (silicon to aluminum ratio (SiO 2 / Al 2 o 3 )=18~30; Relative crystallinity: Na type>85%; Pore diameter: 5A°), placed in 70mL 0.35mol / L NaOH solution, stirred at room temperature for 30min; Treat at ℃ for 3.5h, filter and wash. Put the washed product in a beaker, add 40 mL of 0.5 mol / L sulfuric acid solution, stir at room temperature for 40 min, transfer to a water bath at 80 °C for 3 h, filter, wash, and dry in an oven at 110 °C for 12 h. Solid is ZSM-5 m ;

[0052] b. Preparation of nano-TiO 2 / Mesoporous ZSM-5 m composite photocatalyst.

[0053] Slowly add 10mL of tetrabutyl titanate dropwise to 24mL of absolute ethanol stirred on a magnetic heating stirrer to obtain a yellow transparent solution, which is component A; 20mL of absolute ethanol, 2ml of distilled water and 1....

Embodiment 2

[0057] A preparation method of a photocatalyst for treating nitrophenol wastewater is the same as in Example 1.

[0058] A treatment method for nitrophenol wastewater, comprising the following steps:

[0059] Nano TiO 2 / ZSM-5 m Synergistic degradation of nitrophenol wastewater by photocatalysis and sulfate radicals. 250mL, 50mg / L nitrophenol wastewater was placed in the reactor, and 0.3g nano-TiO 2 / Mesoporous ZSM-5 m Put the composite photocatalyst into the waste water, add 1.26mmol Na 2 S 2 o 8 and 0.54mmol ferrous sulfate, the reaction was initially stirred in a dark state for 30min to reach adsorption equilibrium, and then the nitrophenol wastewater was degraded under the irradiation of a 170W ultraviolet high-pressure mercury lamp for 40min, and the change in the absorbance of nitrophenol was measured to obtain nitrophenol The degradation rate of phenol was 89.7%.

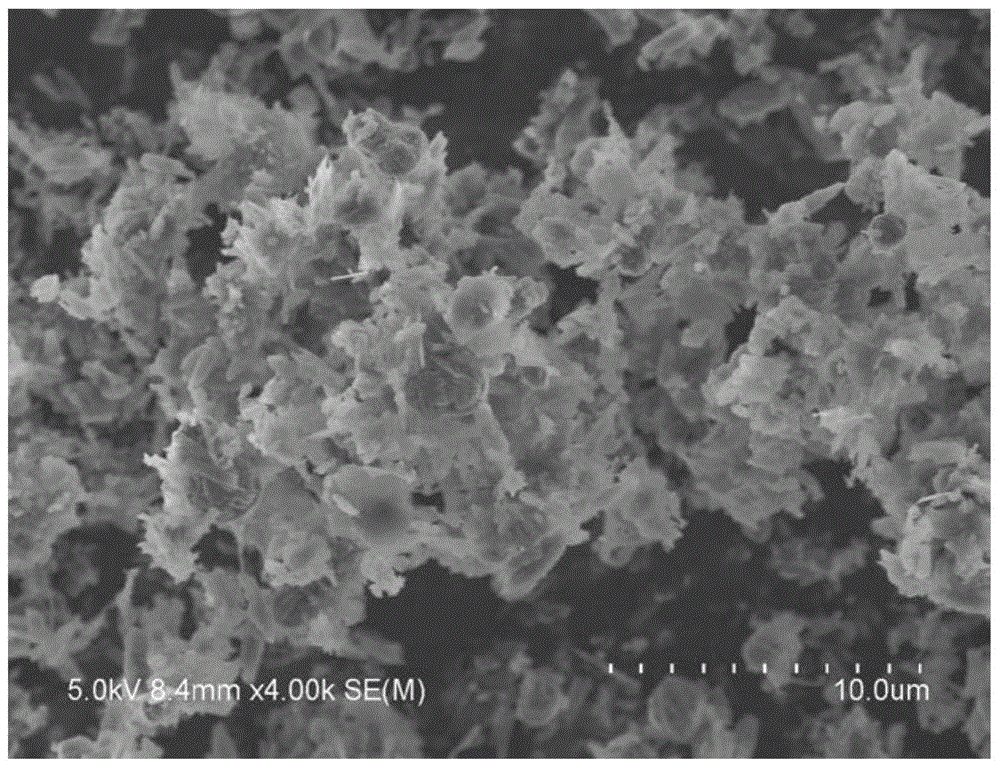

Embodiment 3

[0061] A method for preparing a photocatalyst for treating nitrophenol wastewater, comprising the following steps:

[0062] a. Modified ZSM-5 zeolite;

[0063] Get 1g of commercial ZSM-5 zeolite (silicon to aluminum ratio (SiO 2 / Al 2 o 3 )=18~30; relative crystallinity: Na type>85%; pore size: 5A°), placed in 70mL 0.5mol / L NaOH solution, stirred at room temperature for 30min; ℃ for 4h, filtered and washed. Put the washed product in a beaker, add 50mL of 0.5mol / L sulfuric acid solution, stir at room temperature for 40min, transfer to a 90°C water bath for 4h, filter, wash, and then dry in a 110°C oven for 12h, the obtained Solid is ZSM-5 m ;

[0064] b. Preparation of nano-TiO 2 / Mesoporous ZSM-5 m composite photocatalyst.

[0065] Slowly add 10mL of tetrabutyl titanate dropwise to 24mL of absolute ethanol stirred on a magnetic heating stirrer to obtain a yellow transparent solution, which is component A; mix and stir 20mL of absolute ethanol, 2ml of distilled water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com