Steam exhaust device, electric pressure cooker and exhaust control method

A discharge device and steam technology, applied to pressure cookers, cooking utensils, household appliances, etc., can solve the problems of pressure limiting valve thimble damage, fast outlet speed, loud noise, etc., to reduce impact force and air flow rate, and reduce air leakage risk, the effect of prolonging the transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

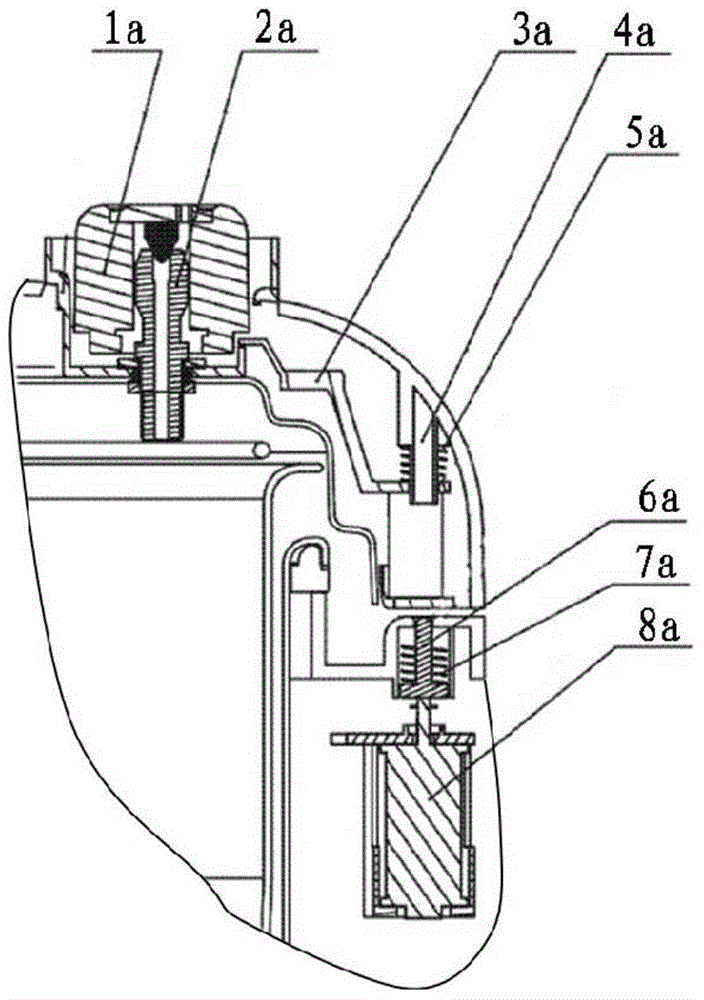

[0042]The inventor noticed that the steam discharge device in the prior art produces relatively loud noises and is easy to burn hands when manually operated. The main reason is that in this structural mode, after the pressure limiting valve 1a is lifted, the pressure chamber in the pot is in contact with the outside world. It is directly connected through the exhaust pipe 2a, and the high-pressure water vapor is directly discharged through a short straight channel, and a high pressure is still maintained at the outlet. Therefore, it is necessary to design a new steam discharge device to buffer the impact force of the gas discharge, so as to reduce the noise.

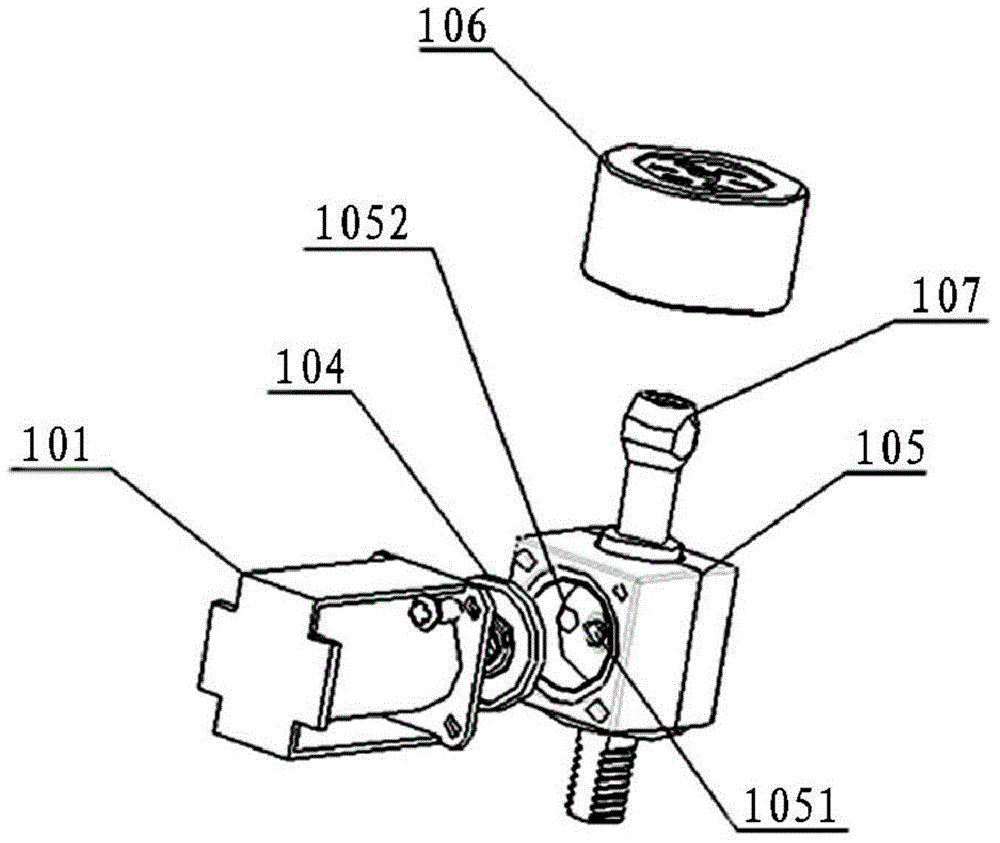

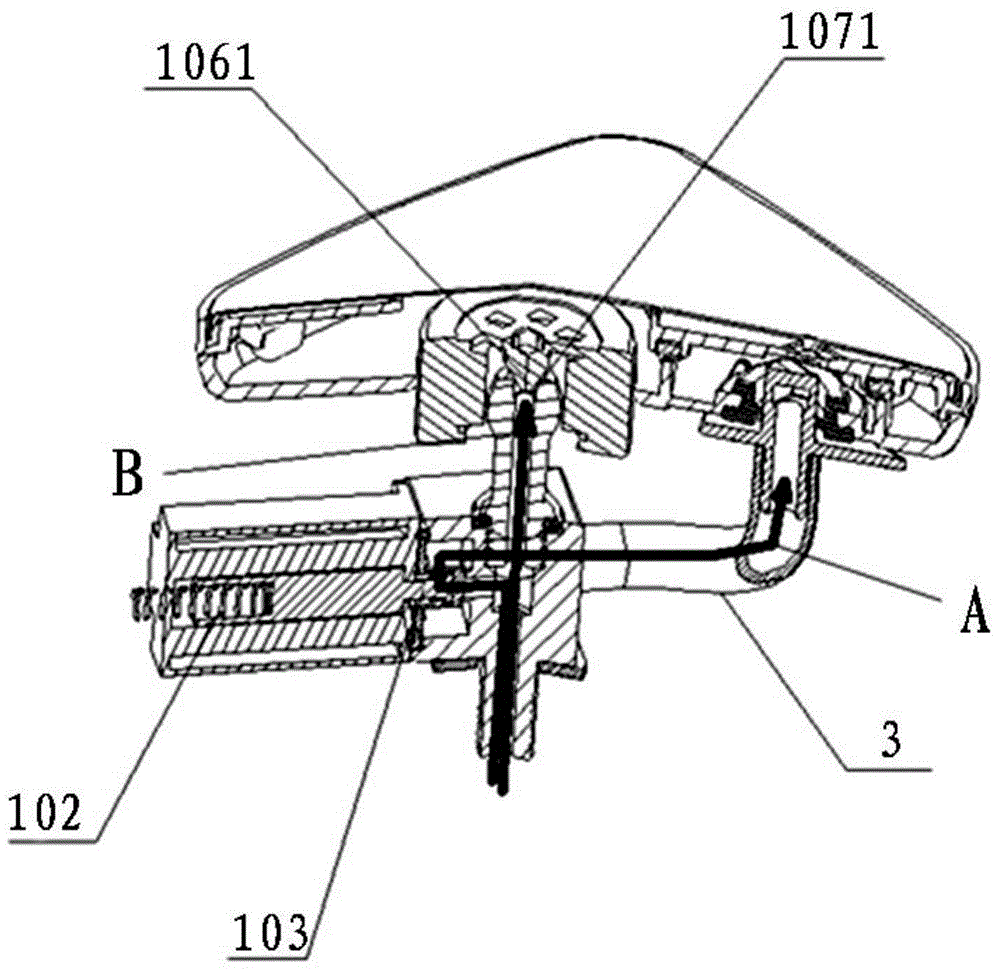

[0043] A steam discharge device provided by the present invention, such as figure 2 The exploded view of the exhaust assembly shown and image 3 The schematic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com