Preparation method of flower-shaped molybdenum disulfide microspheres

A technology of molybdenum disulfide and microspheres, which is applied in the directions of molybdenum sulfide, electrical components, battery electrodes, etc., can solve the problems of complicated preparation process, long reaction time of preparation process, etc., and achieves low cost, high product yield, good shape uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Dissolve 1.24g of ammonium molybdate tetrahydrate into 36mL of deionized water to prepare a 0.03mol / L solution, then add 2.28g of thiourea, stir for 20min with a magnetic stirrer, and transfer the stirred solution to a volume of 50mL of water In a thermal reaction kettle; conduct a hydrothermal reaction at 220°C for 6 hours, then cool naturally, centrifuge, wash with deionized water and ethanol, and then dry to obtain molybdenum disulfide microspheres.

Embodiment 2

[0019] Dissolve 2.22g of ammonium molybdate tetrahydrate into 36mL of deionized water to prepare a 0.05mol / L solution, then add 2.28g of thiourea, stir with a magnetic stirrer for 30min, and transfer the stirred solution to a volume of 50mL of water In a thermal reaction kettle; conduct a hydrothermal reaction at 240°C for 8 hours, then cool naturally, centrifuge, wash with deionized water and ethanol, and then dry to obtain molybdenum disulfide microspheres.

Embodiment 3

[0021] Dissolve 0.89g of ammonium molybdate tetrahydrate into 36mL of deionized water to prepare a 0.02mol / L solution, then add 1.09g of thiourea, stir for 20min with a magnetic stirrer, and transfer the stirred solution to a volume of 50mL of water In a thermal reaction kettle; conduct a hydrothermal reaction at 220°C for 4 hours, then cool naturally, centrifuge, wash with deionized water and ethanol, and then dry to obtain molybdenum disulfide microspheres.

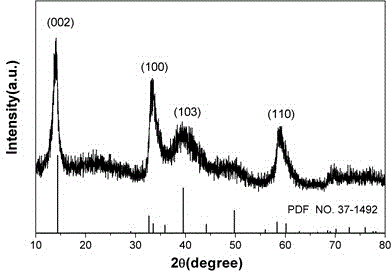

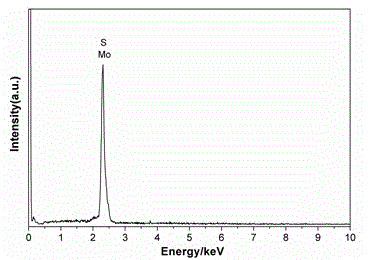

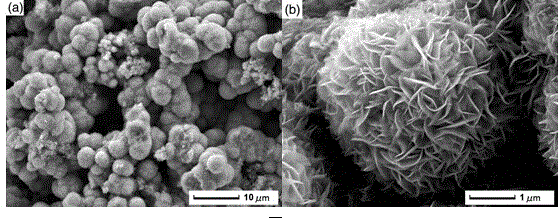

[0022] figure 1 It is the XRD pattern of the product prepared in embodiment 1, and the product is pure MoS 2 hexagonal crystal; figure 2 It is the EDS spectrum of the product prepared in Example 1. There are only S and Mo elements in the figure, and the atomic ratio of the two elements is 1.98:1, indicating that the prepared product is pure MoS 2 ; image 3 Be the SEM photograph of the product prepared in embodiment 1, from the SEM photograph of low magnification image 3 In a, it can be clearly seen that the sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com