Method for modifying lead storage battery positive plate by rare earth

A lead-acid battery, positive plate technology, applied in lead-acid battery electrodes, lead-acid batteries and other directions, can solve the problems of reduced utilization rate of positive active materials, polluted ambient temperature, inconsistent use conditions, etc., and is conducive to large-scale industrialization, electricity The effect of good chemical performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

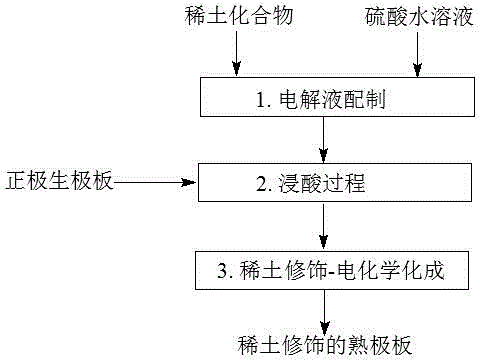

[0049] A method for modifying the positive plate of a lead storage battery with rare earths. During the formation process of the positive plate of the lead storage battery, rare earth sulfate or rare earth oxide is added to the battery formation solution, and the rare earth ions undergo an oxidation reaction at the anode to modify the positive plate of the lead storage battery. While the lead compound on the plate is converted into lead dioxide, the rare earth modification of the positive electrode grid and positive active material of the battery is realized, and the performance of the lead storage battery is improved, and the method is characterized in that the steps of the method are as follows:

[0050] (1) Preparation of battery formation solution: In the stirring tank formation solution preparation equipment, water, sulfuric acid and cerium sulfate are mixed to prepare a battery formation solution of 1.8mol / L sulfuric acid and 0.001mol / L Ce3+;

[0051](2) Pickling process ...

Embodiment 2

[0054] A method for modifying the positive plate of a lead storage battery with rare earths. During the formation process of the positive plate of the lead storage battery, rare earth sulfate or rare earth oxide is added to the battery formation solution, and the rare earth ions undergo an oxidation reaction at the anode to modify the positive plate of the lead storage battery. While the lead compound on the plate is converted into lead dioxide, the rare earth modification of the positive electrode grid and positive active material of the battery is realized, and the performance of the lead storage battery is improved, and the method is characterized in that the steps of the method are as follows:

[0055] (1) Preparation of battery formation solution: In a stirred tank or tubular mixed formation solution preparation equipment, mix water, sulfuric acid, cerium Ce, praseodymium Pr and rare earth sulfate formed by lanthanum to prepare 4.8mol / L sulfuric acid, 0.010mol / L Ce3+, 0.0...

Embodiment 3

[0059] A method for modifying the positive plate of a lead storage battery with rare earths. During the formation process of the positive plate of the lead storage battery, rare earth sulfate or rare earth oxide is added to the battery formation solution, and the rare earth ions undergo an oxidation reaction at the anode to modify the positive plate of the lead storage battery. While the lead compound on the plate is converted into lead dioxide, the rare earth modification of the positive electrode grid and positive active material of the battery is realized, and the performance of the lead storage battery is improved, and the method is characterized in that the steps of the method are as follows:

[0060] (1) Preparation of battery formation solution: In a stirred tank or tubular mixed formation solution preparation equipment, water, sulfuric acid, and three kinds of variable-value rare earth elements in cerium Ce, praseodymium Pr, and terbium Tb are mixed with rare earth sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com