Novel GaN-base reinforced HEMT device and manufacturing method thereof

An enhanced device technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as low threshold voltage, potential safety hazards of depletion devices, and increase the difficulty and cost of circuit design. Design difficulty and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

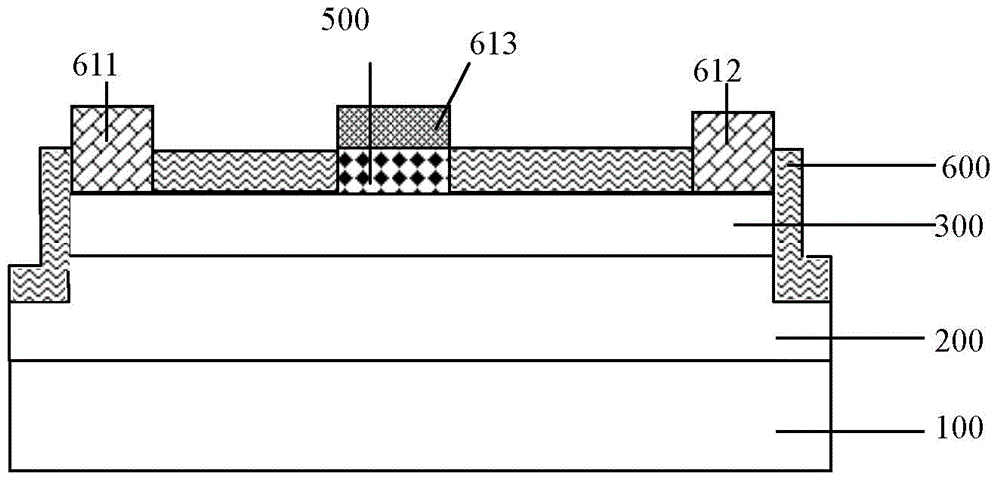

[0036] figure 1 It is a schematic structural diagram of a GaN-based enhancement mode HEMT device according to an embodiment of the present invention, such as figure 1 As shown, in an embodiment of the present invention, the GaN-based enhanced HEMT device includes: a substrate 100, a GaN intrinsic layer 200, a barrier layer 300, a high hole concentration structure layer 500, a first metal electrode 611, a second The second metal electrode 612, the third metal electrode 613 and the passivation protection layer 600, wherein:

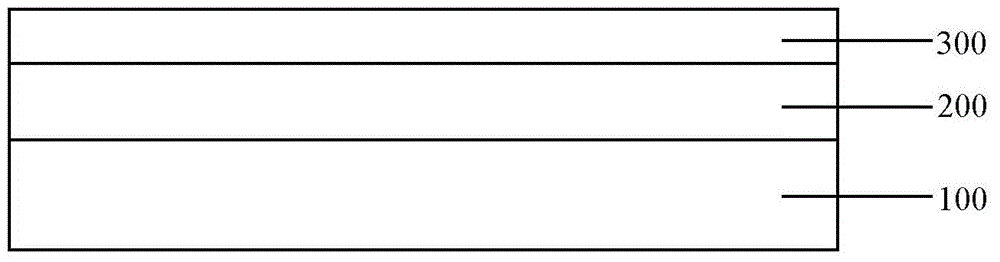

[0037] The GaN intrinsic layer 200 and the barrier layer 300 are sequentially grown on the substrate 100;

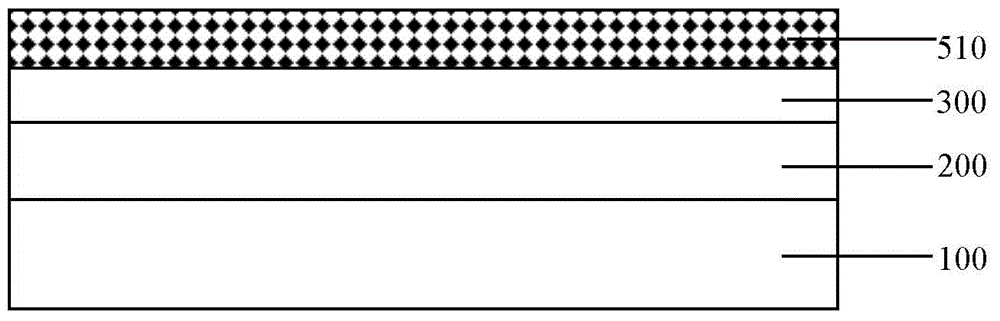

[0038] The high hole concentration structure layer 500 covers a part of the upper surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com