Novel optical fiber sensor for detecting surface defects of steel balls and detection method

An optical fiber sensor and a technology for detecting steel balls, which are applied in the field of precision measurement, can solve the problems of high false detection rate, affect the detection results, restrict the development of the steel ball industry, etc., and achieve the effects of convenient and accurate installation and positioning, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

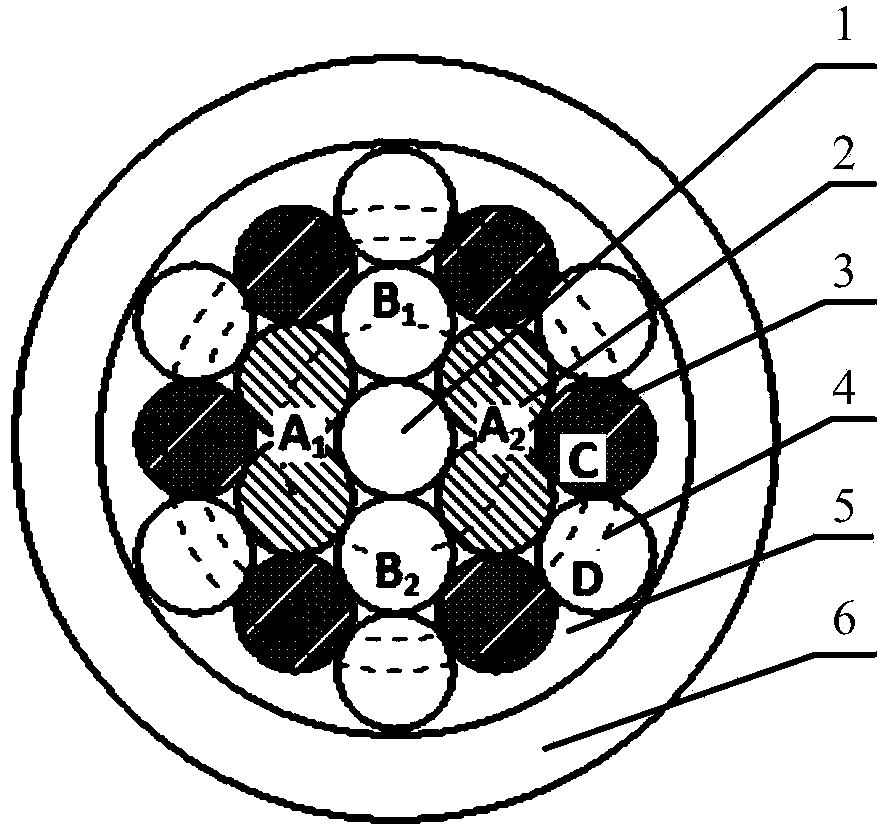

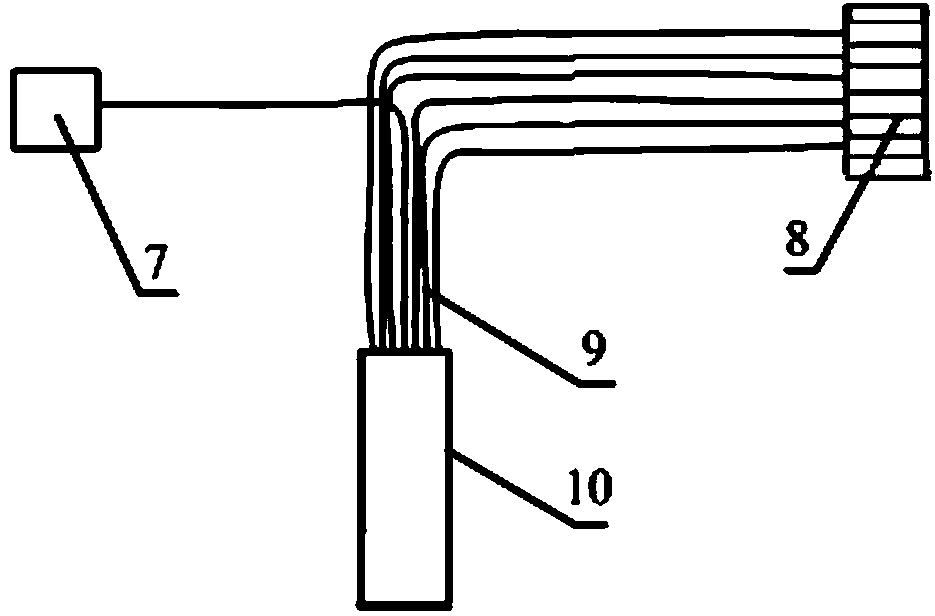

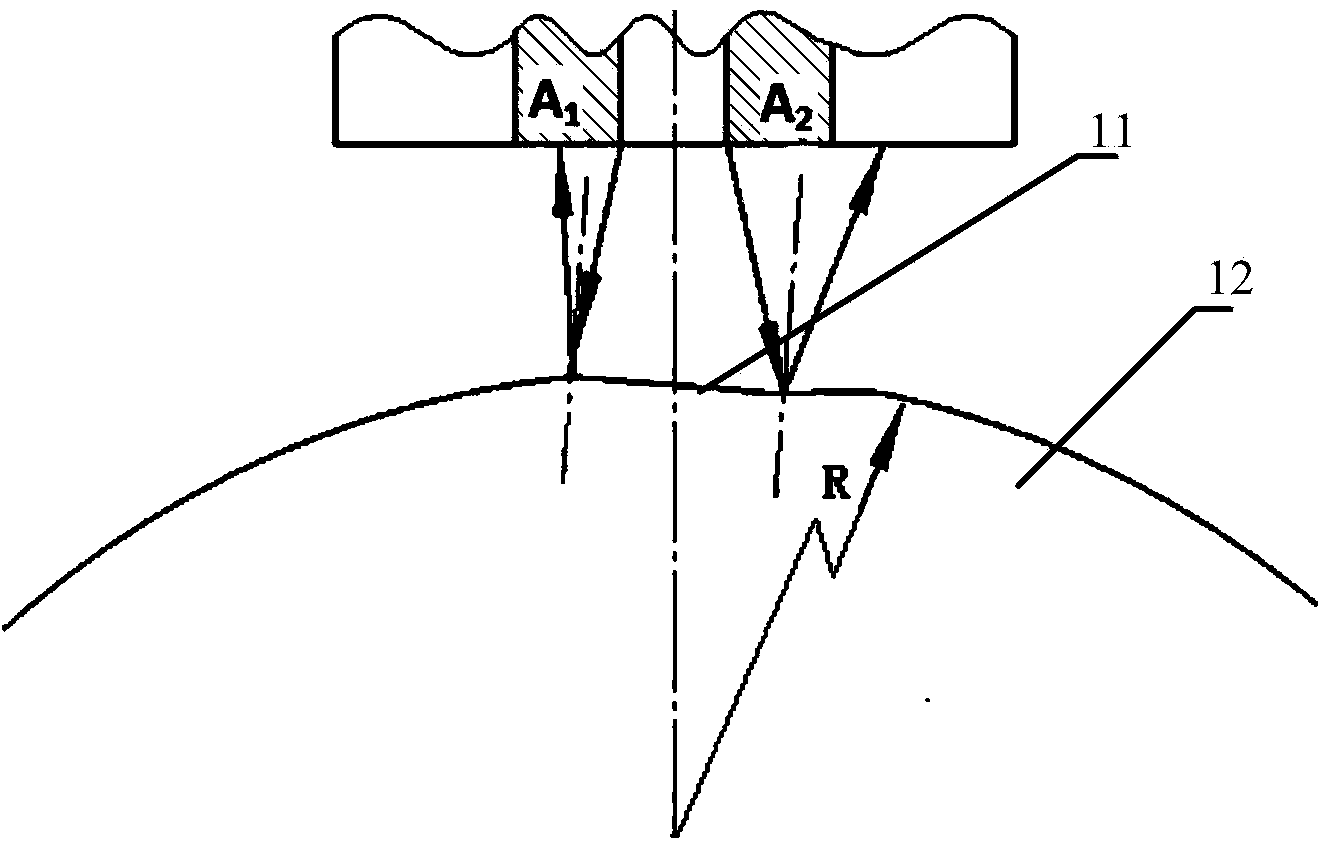

[0045] Such as figure 1 , figure 2 As shown, the present invention is used for the detection of surface defects 11 of the steel ball 12 to be tested, including a laser light source 7, a photoelectric converter 8, and a sensor probe 10. The sensor probe 10 is composed of an optical fiber bundle 9, an optical fiber fixing filler 5, and a housing 6. .

[0046]Optical fiber bundle 9 comprises 19 optical fibers, and it comprises emitting optical fiber and receiving optical fiber bundle, and described emitting optical fiber and receiving optical fiber bundle are arranged in a two-dimensional hexagonal shape, and the axis is the emitting optical fiber, and from the axis to the outer circle is receiving Optical fiber, the six optical fibers closest to the transmitting optical fiber are crossed and orthogonally received optical fiber 2 is divided into four pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com