Full-automatic environment-friendly and energy-saving gas stove

An environment-friendly, energy-saving, gas stove technology, applied in the field of stoves, can solve problems such as environmental pollution, fuel waste, and waste, and achieve the effects of easy manufacturing, low cost, and saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

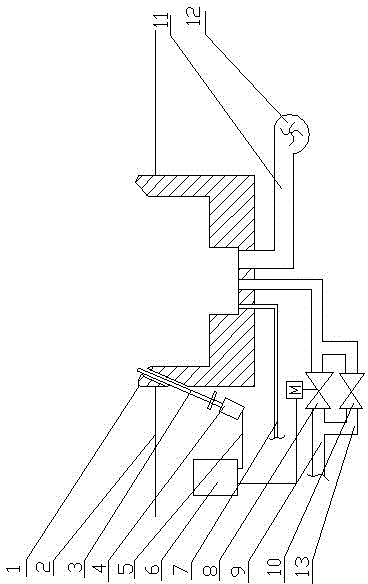

[0017] See attached figure 1 In this embodiment of the fully automatic environment-friendly and energy-saving gas cooker of the present invention, the cooker table 2 and the cooker body 1 are made of stainless steel plate profiles with a thickness of 0.3 cm. Rod 3 cross-sectional diameter size matching. The slide rod 3 is inserted into the hole, and it is required to freely slide up and down in the hole. A pressure touch switch 4 is provided at the lower end of the slide bar 3 . Corresponding to the pressure switch 4 is a control box equipped with a DC power supply and a relay 6 . The pressure touch switch 4 is electrically connected to the above DC power supply and relay 6 . The relay 6 is electrically connected to the electric ball valve 8 . In addition, a main air supply pipe 9, a small fire air supply pipe 7 and a blower 12 air supply pipe 11 are connected and welded in the traditional way at the lower end of the stove body 1. The main air supply pipeline 9 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com