Roller-hearth type plate continuous tempering furnace and tempering method thereof

A tempering furnace and roller hearth technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of high investment cost, easy deformation of steel plates, waste of production capacity, etc., and achieve high furnace temperature control accuracy, uniform heating of plates, and switching Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0026] The invention proposes a continuous tempering furnace for roller hearth plates.

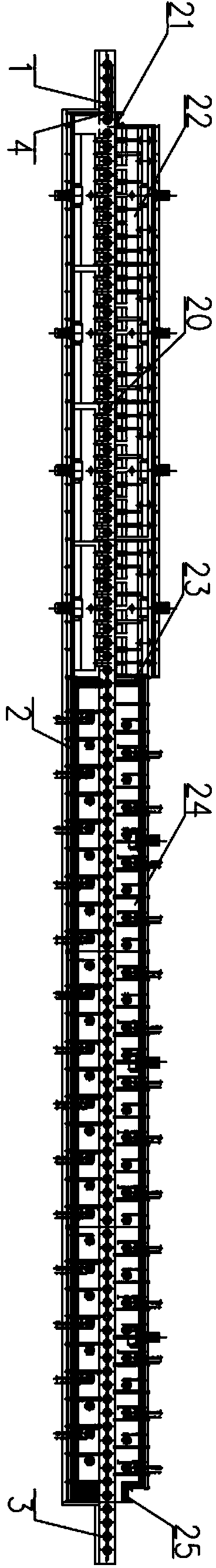

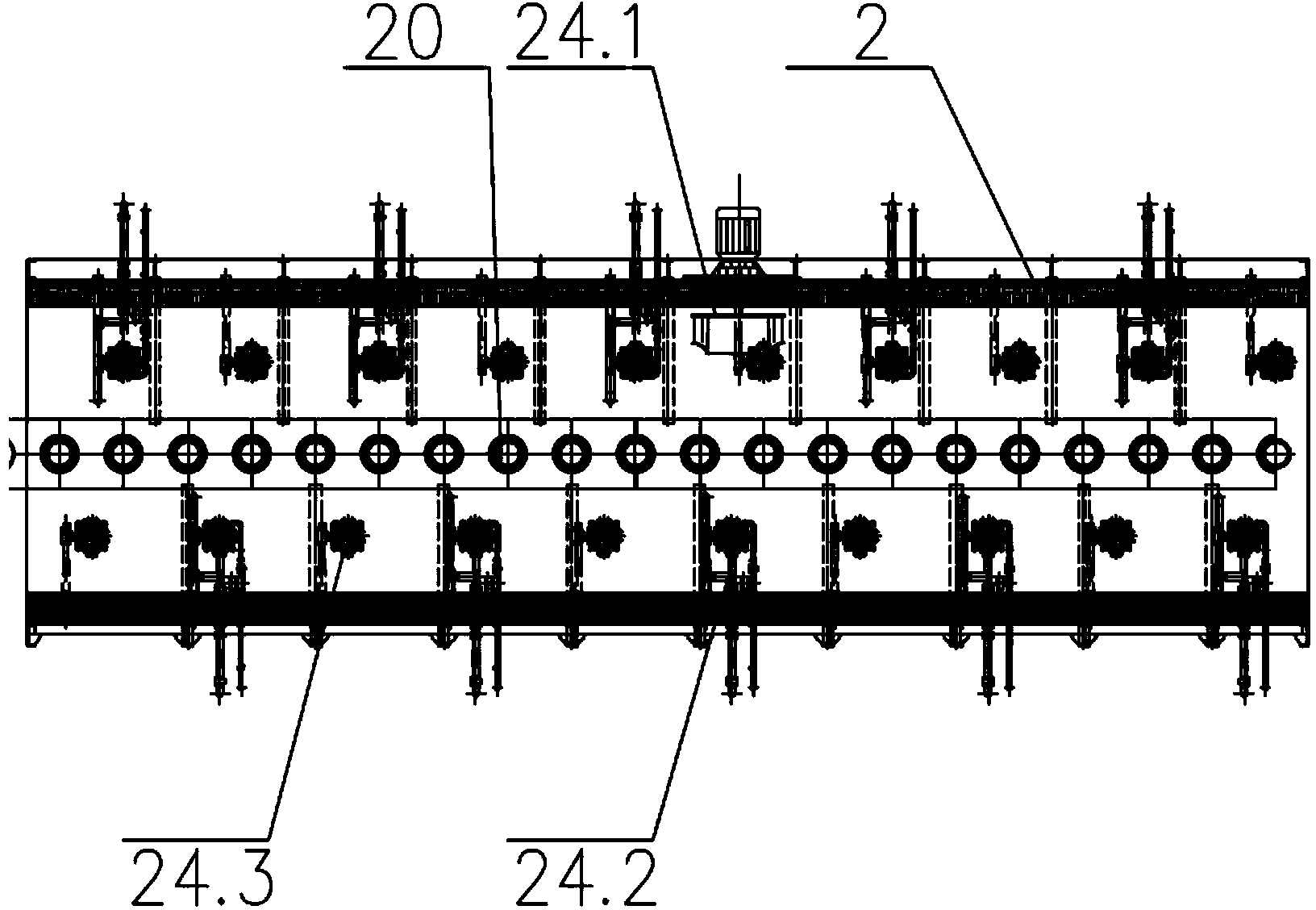

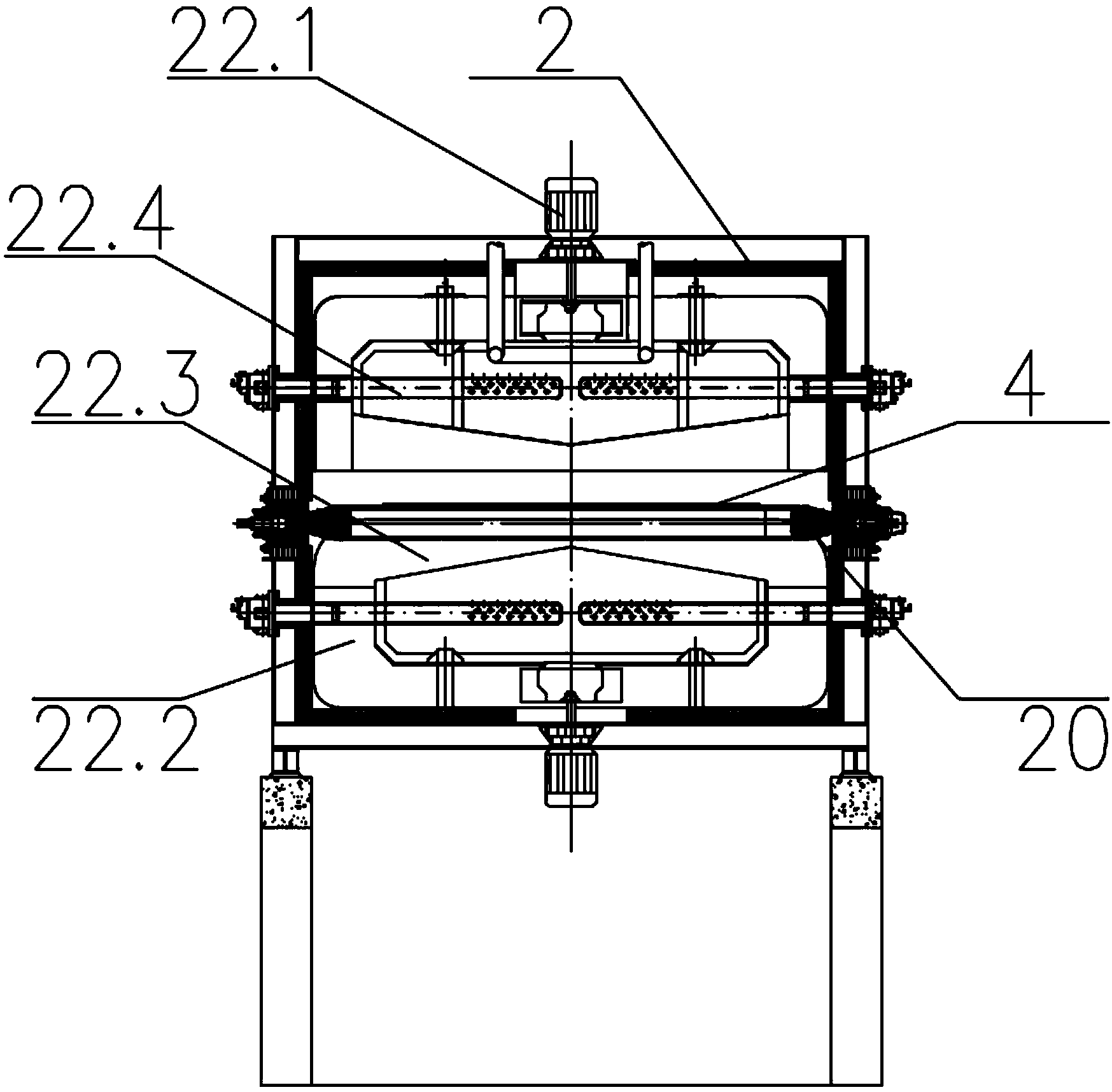

[0027] refer to Figure 1 to Figure 4 , figure 1 It is a structural schematic diagram of a preferred embodiment of the roller hearth type plate continuous tempering furnace of the present invention; figure 2 It is a schematic diagram of the local structure of the open flame heating / insulation section in the preferred embodiment of the roller hearth type plate continuous tempering furnace of the present invention; image 3 It is a schematic cross-sectional structure diagram of the strong convection heating section in the preferred embodiment of the roller hearth type plate continuous tempering furnace of the present invention; Figure 4 It is a schematic cross-sectional structure diagram of the open flame heating / holding sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com