Heat treatment furnace with movable furnace cover

A heat treatment furnace and mobile technology, applied in the field of heat treatment, can solve the problems of poor annealing effect, high energy consumption, unreasonable structure, etc., and achieve the effect of reducing heat dissipation loss, reducing heat dissipation area, and good atomization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

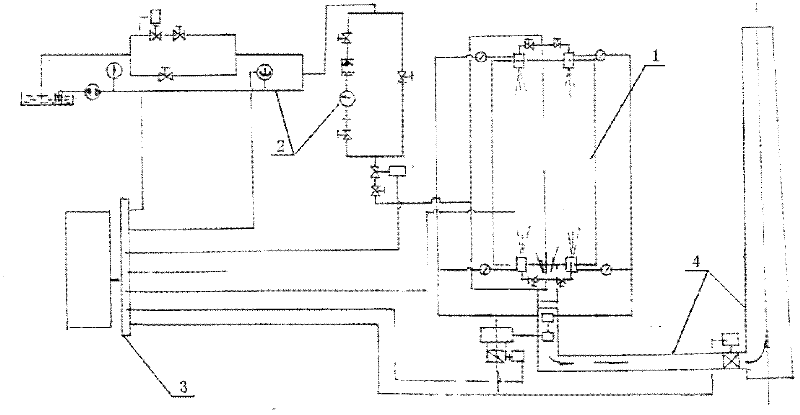

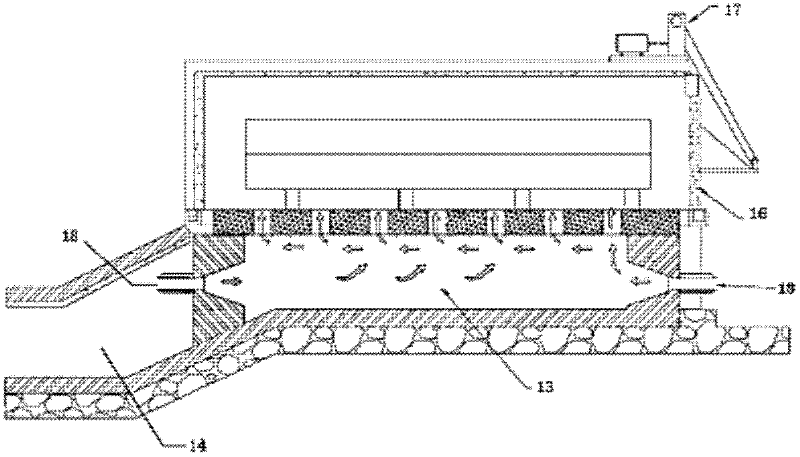

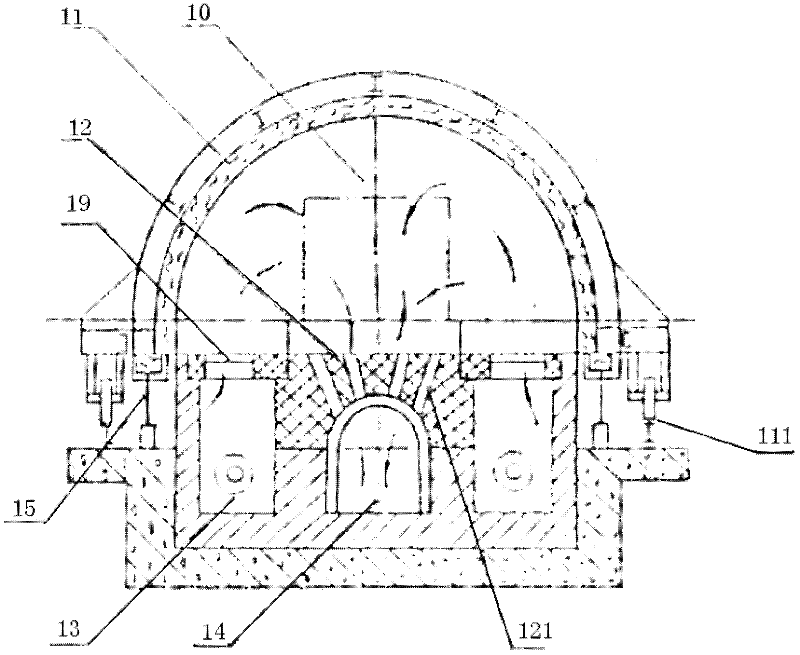

[0029] Such as Figure 1-Figure 3 As shown, the hood mobile heat treatment furnace 1 is connected to the combustion system 2, the measurement and control system 3, and the smoke exhaust system 4. It includes a furnace base 12, and the furnace base 12 is provided with two combustion chambers 13 and a flue 14, wherein the flue 14 is located in the middle of the two combustion chambers 13 and is connected to the smoke exhaust system 4 for exhausting flue gas; each end of the combustion chamber 13 is provided with a burner 18, a total of 4 burners 18 in the whole furnace, of which, the burner 18 It is connected to the fuel system 2 and receives the fuel supply of the fuel system 2; the upper surface of the furnace table is provided with a movable furnace cover 11, and both ends of the furnace cover 11 are provided with furnace doors 16 equipped with furnace door lifting mechanisms (furnace door lifting mechanisms are also provided 17) The inner space of the furnace hood 11 is the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com