Preparation method and application of liquid complex microbial inoculant

A compound bacterial agent and liquid technology, applied in the field of environmental pollution control, can solve the problems of inability to maintain metabolic activities, additional regular adjustments, etc., and achieve the effects of low growth and degradation activity, large number of viable bacteria, and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

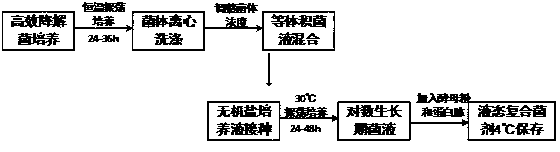

[0032] See figure 1 , The preparation method of the compound bacterial agent of the present invention is as follows:

[0033] (1) Obtain the bacterial suspension

[0034] Pick the above-mentioned colonies from the preservation medium and inoculate them into the inorganic salt solution medium. After culturing for 48-64h with α-pinene, 1-chlorobenzene, dichloromethane, o-xylene and acetic acid as the sole carbon source, the different A bacterial suspension of the strain.

[0035] The said inorganic salt culture solution (g / L): KH 2 PO 4 0.376, K 2 HPO 4 ·3H 2 O 0.456, (NH 4 ) 2 SO 4 0.484, NaNO 3 0.68, Mg(NO 3 ) 2 0.256, CaCl 2 0.011, trace element (MnCl 2 ·H 2 O 0.06, ZnCl 2 0.088, KI 0.01, NaMoO 4 ·2H 2 O 0.1, H 3 BO 3 0.05), pH=7.2.

[0036] (2) Obtaining mixed bacterial seed liquid

[0037] After centrifuging the bacterial suspension of various bacteria under the condition of 12000g, the bacteria are collected, and washed with sterile water 3 times, and a certain volume of st...

Embodiment 2

[0041] Place the prepared liquid composite inoculum in a refrigerator (4°C) and store it for 1 week, 2 weeks, 4 weeks, and 8 weeks respectively. The number of active bacteria in the liquid inoculum was investigated by the plate counting method. The results are shown in Table 1. The number of effective viable bacteria contained in the freshly prepared liquid bacterial agent is 7.6×10 respectively 9 CFU / mL. The number of corresponding viable bacteria decreased slightly after storage for different time, and with the increase of storage time, the downward trend was obvious, but it remained at 10 8 Above CFU / mL. The attenuation of the number of viable bacteria in the composite liquid inoculum is small, which may be due to the low bacterial activity at low temperatures. At the same time, yeast powder and peptone can be used as carbon sources to maintain the activity of the strains at low temperatures, so that the activity of the inoculum is maximized and effectively stored The time ...

Embodiment 3

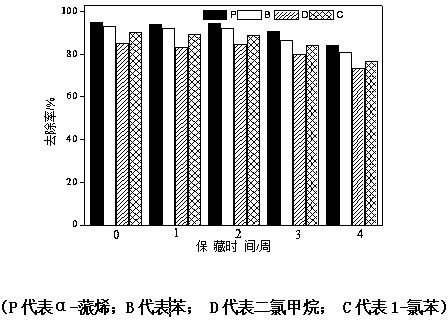

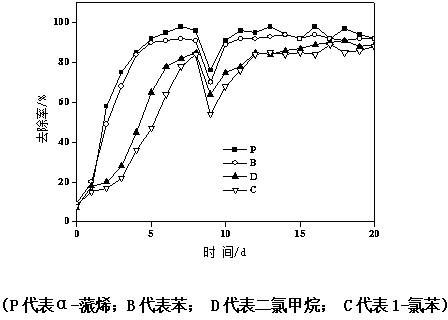

[0044] Place the prepared liquid composite inoculum in a refrigerator (4°C), and test the degradation activity of the inoculum after 1 week, 2 weeks, 4 weeks, and 8 weeks. The specific steps are as follows: After taking out the liquid compound bacterial agent, place it at room temperature, centrifuge at 12000g, collect the bacterial cells, wash them with sterile water 3 times, inoculate them into an inorganic salt liquid medium, and add mixed organic pollutants ( α-pinene, 1-chlorobenzene, methylene chloride, toluene), the concentration of each pollutant is 100mg / L. Place it on a shaker and shake culture at a temperature of 30℃. After culturing for 48 hours, analyze the concentration of each pollutant in the liquid. The results are as follows figure 2 Shown.

[0045] It can be seen that the degradation activity of the liquid bacterial agent is almost unchanged after being stored at 4°C for 1 week and 2 weeks, indicating that the degradation stability is better; after 4 weeks and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com