Preparation method of compound slow-breaking slow-curing positive ion asphalt emulsifier

An asphalt emulsifier, slow-cracking and slow-setting technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of unsatisfactory asphalt emulsion stability, high cost, unsatisfactory demulsification and molding conditions, etc. Enhance water solubility and emulsifying ability, no three wastes discharge, wide adaptability of stone materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

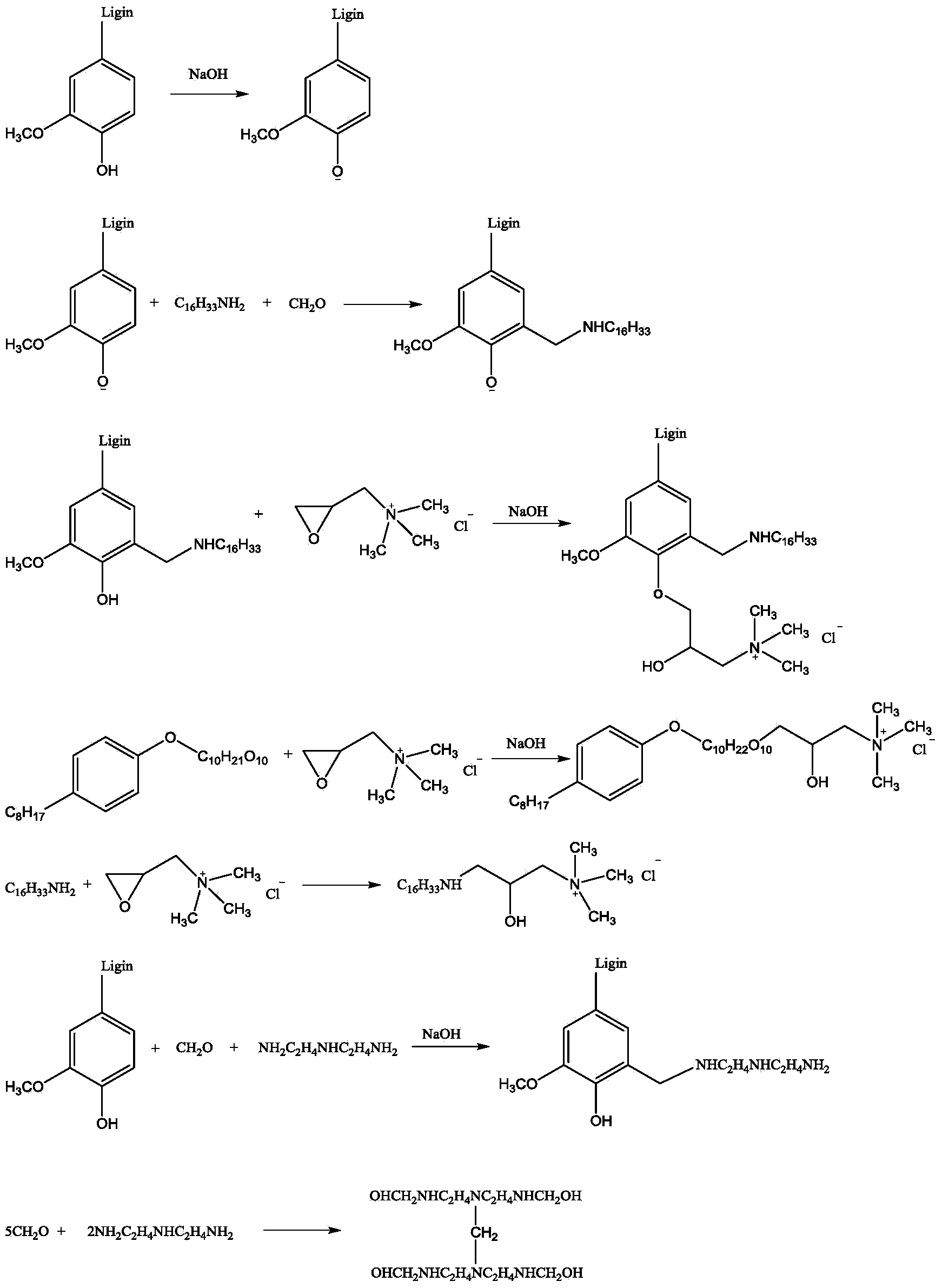

Method used

Image

Examples

Embodiment 1

[0028] Preparation of emulsifier

[0029] Dissolve 8g of lignin in 35g of water, adjust the pH of the solution to 9 with sodium hydroxide, add 2g of dodecylamine to the system, after the system is heated to 65°C, add 0.4g of paraformaldehyde, react for 1 hour, add Glycidyltrimethylammonium chloride (ETA) 12g, after reacting for 7 hours, add 40g OP-13, continue to react after 1.5 hours, add 1g triethylenetetramine and 0.5g paraformaldehyde, continue to react for 1.5 hours, The slow-cracking and slow-setting cationic asphalt emulsifier of the present invention is obtained by adding 50% methanol solution for dilution.

[0030] Preparation of asphalt emulsion

[0031] Weigh 10g of the above-prepared emulsifier (effective content is 50%), add about 170ml of water, stir gently, after the emulsifier is completely dissolved, adjust the pH of the solution to 2.0 with hydrochloric acid, and set the volume to 200ml to obtain emulsified agent aqueous solution. Turn on the emulsified co...

Embodiment 2

[0035] Preparation of emulsifier

[0036] Dissolve 8g of lignin in 35g of water, adjust the pH value of the solution to 9 with sodium hydroxide, add 4g of octadecylamine to the system, after the system is heated to 75°C, add 0.3g of paraformaldehyde, react for 1 hour, add Epoxypropyltrimethylammonium chloride (ETA) 14g, after reacting for 3 hours, add 25g TX-15, after continuing to react for 1 hour, add 2g tetraethylenepentamine and 0.6g paraformaldehyde, continue reacting for 1 hour, The slow-cracking and slow-setting cationic asphalt emulsifier of the present invention is obtained by adding 50% methanol solution for dilution.

[0037] The preparation of asphalt emulsion is the same as that in Example 1.

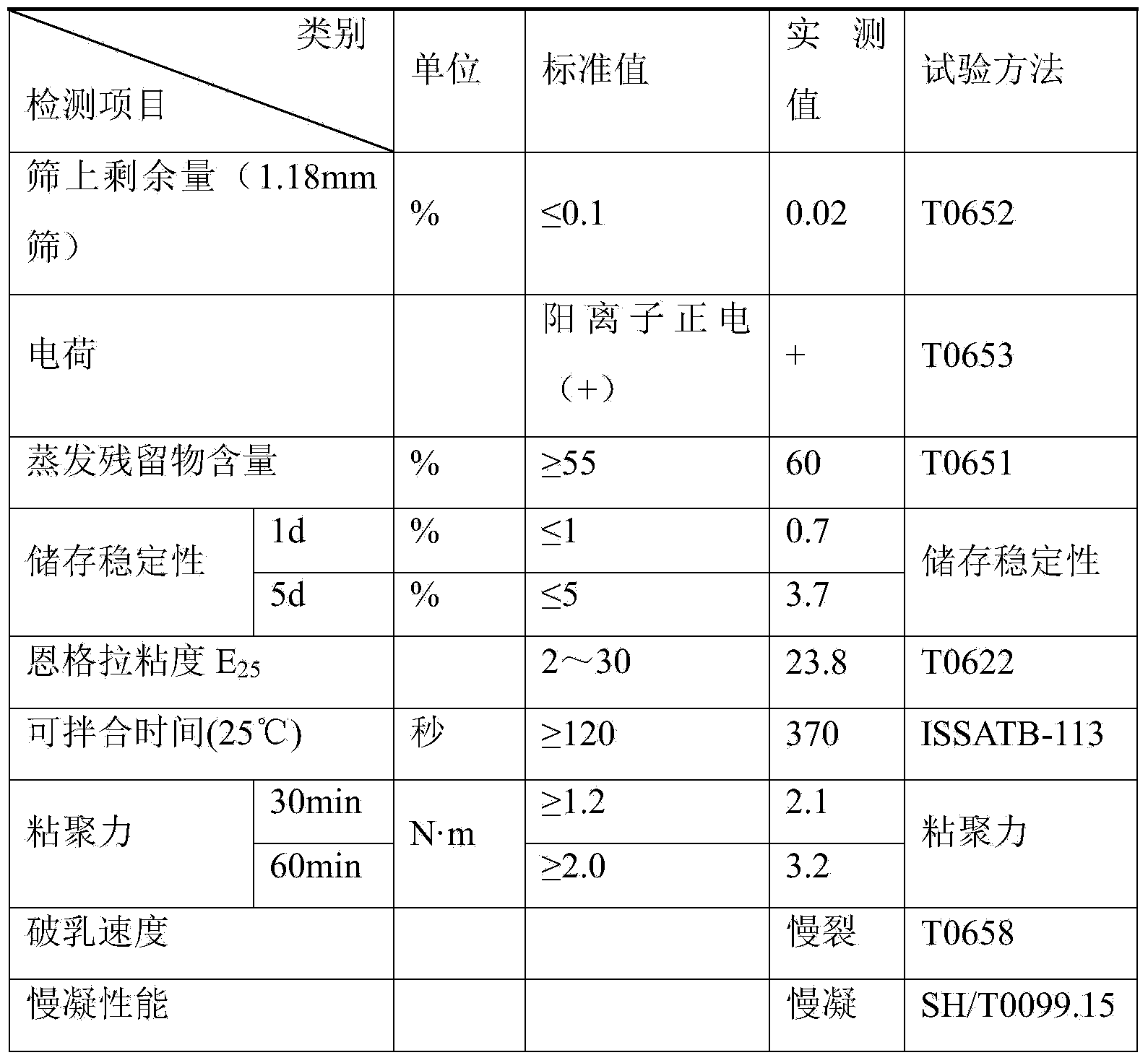

[0038] Asphalt Emulsion Performance Test

[0039]

[0040]

Embodiment 3

[0042] Preparation of emulsifier

[0043] Dissolve 8g of lignin in 35g of water, adjust the pH of the solution to 10 with sodium hydroxide, add 2g of hexadecylamine to the system, after the system is heated to 65°C, add 0.3g of paraformaldehyde, react for 1.5 hours, add Glycidyltrimethylammonium chloride (ETA) 10g, after reacting for 4 hours, add 20g TX-15 and 20g AC-1815, after continuing the reaction for 1.5 hours, add 1g diethylenetriamine and 0.5g paraformaldehyde, Continue to react for 1.5 hours, add 50% methanol solution to dilute to obtain the slow-cracking and slow-setting cationic asphalt emulsifier of the present invention.

[0044] The preparation of asphalt emulsion is the same as that in Example 1.

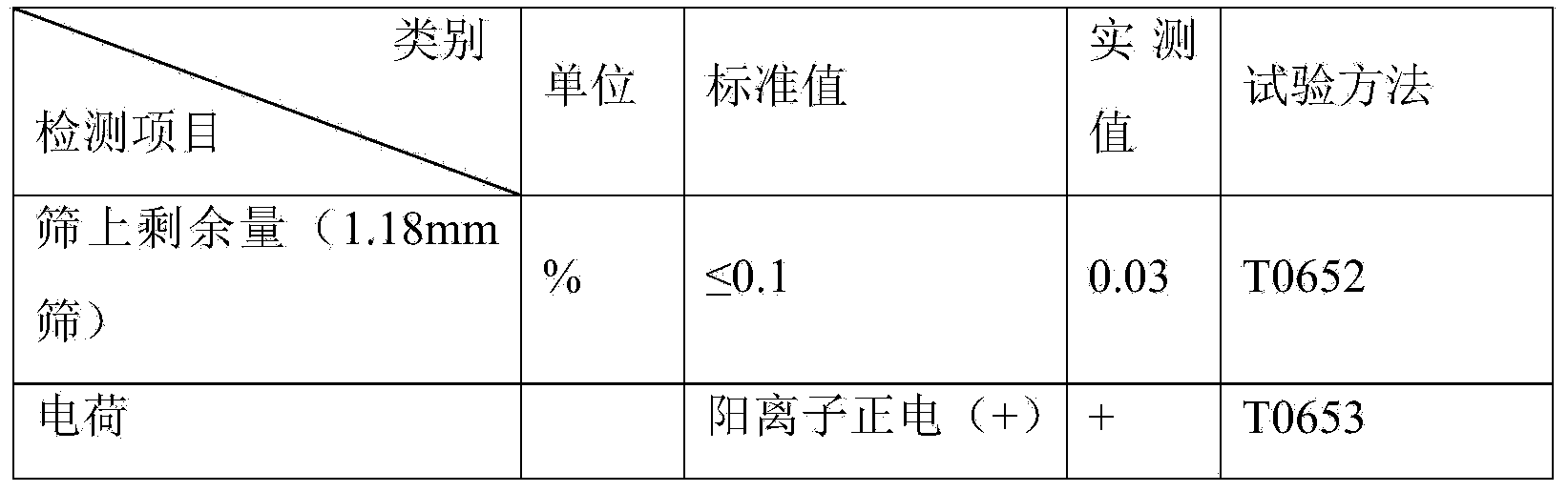

[0045] Asphalt Emulsion Performance Test

[0046]

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com