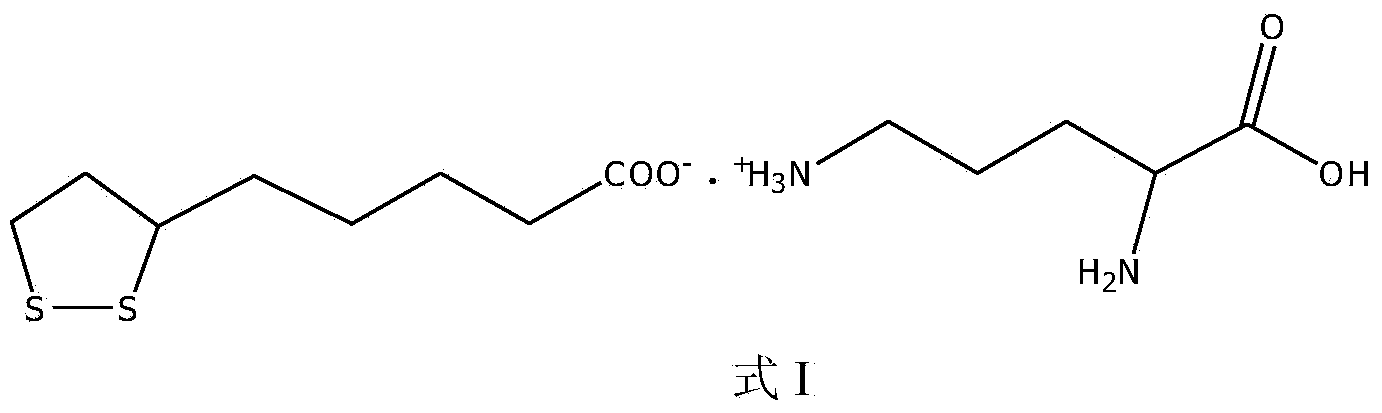

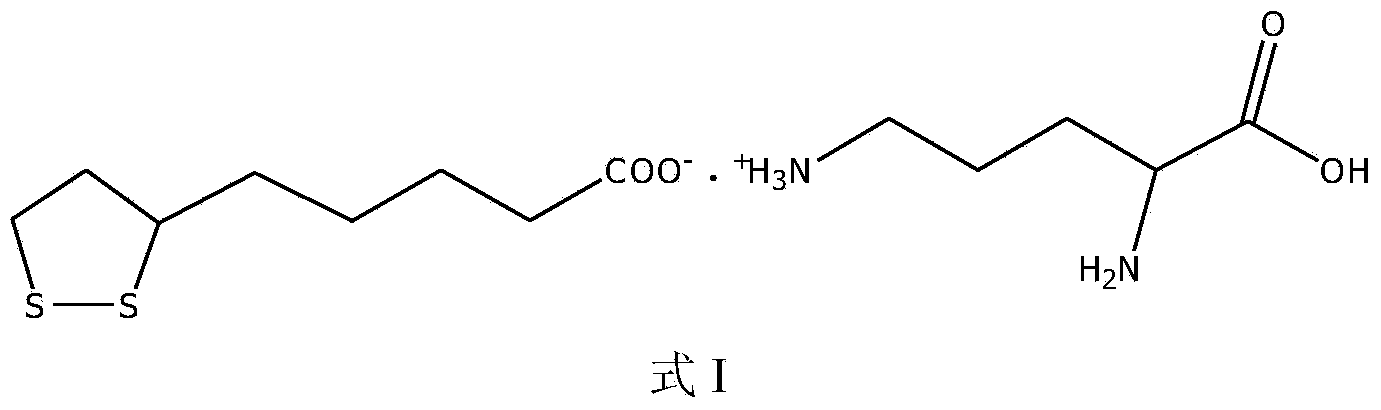

L-ornithine lipoic acid compound salt, and preparation method and application thereof

A technology of ornithine sulfur and compound salt is applied in the field of medicine and achieves the effects of low cost, high purity and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

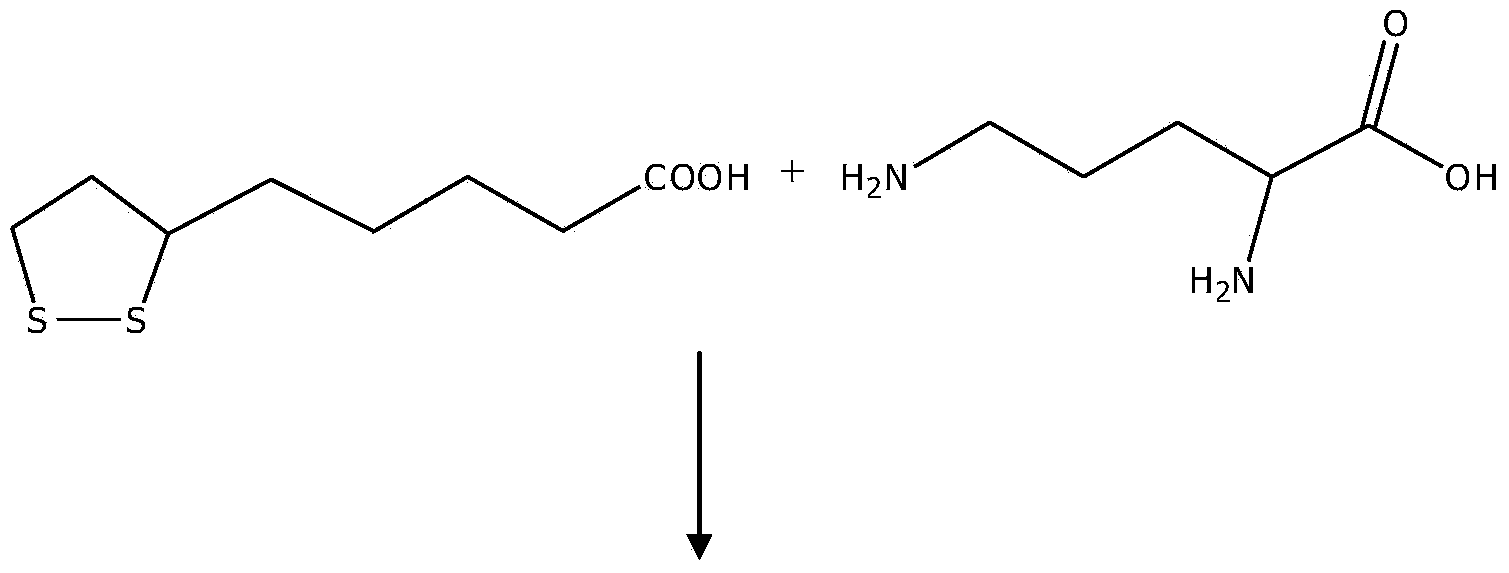

[0045] Embodiment 1: Preparation of L-ornithine lipoic acid compound salt

[0046] Step 1: Preparation of free L-ornithine

example 1

[0048] Dissolve 30g of L-ornithine hydrochloride in 1L of water, adjust its pH to 2.0 with hydrochloric acid, then flow the adjusted pH-adjusted L-ornithine hydrochloride solution through the filling chamber at a flow rate of 6ml / min The ion-exchange column of JK006 cation exchange resin, and then rinse the column with deionized water to wash away the chloride ions between the resins, and finally use 0.8mol / L ammonia water to flow through the column at a flow rate of 8ml / min to release the free L-ornithine Eluted from the resin, free L-ornithine aqueous solution was obtained.

example 2

[0050] According to the method disclosed in the patent document CN101955901, a fermented liquid containing L-ornithine is obtained, and after the fermented liquid is treated by removing bacteria and pigment, an aqueous solution containing free L-ornithine is obtained.

[0051] Step 2: preparing L-ornithine lipoic acid compound salt;

[0052] example 1:

[0053] Concentrate the free L-ornithine aqueous solution in Step 1 Example 1, and the concentration of free L-ornithine in the obtained concentrated solution is 54.7wt%. Dissolve 20g of lipoic acid in 400ml of absolute ethanol, add 22.5g of the above-mentioned free L-ornithine concentrate to it, and stir at a constant temperature of 20°C for 120min to complete the reaction and obtain an ethanol-insoluble precipitate, which is filtered to remove the solid-liquid mixture Ethanol, put the filtered solid into a blast drying oven, and dry at 40° C. for 6 to 8 hours to obtain 28.98 grams of light yellow solid powder. The above yel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com