Process for separating ethylbenzene from C8 arene

A C8 aromatic hydrocarbon and process technology, which is applied in the technical field of separating ethylbenzene, can solve the problems of complex production operation, harsh operating conditions, high price, etc., and achieves the effects of remarkable separation effect, reduction of the number of trays, and easy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

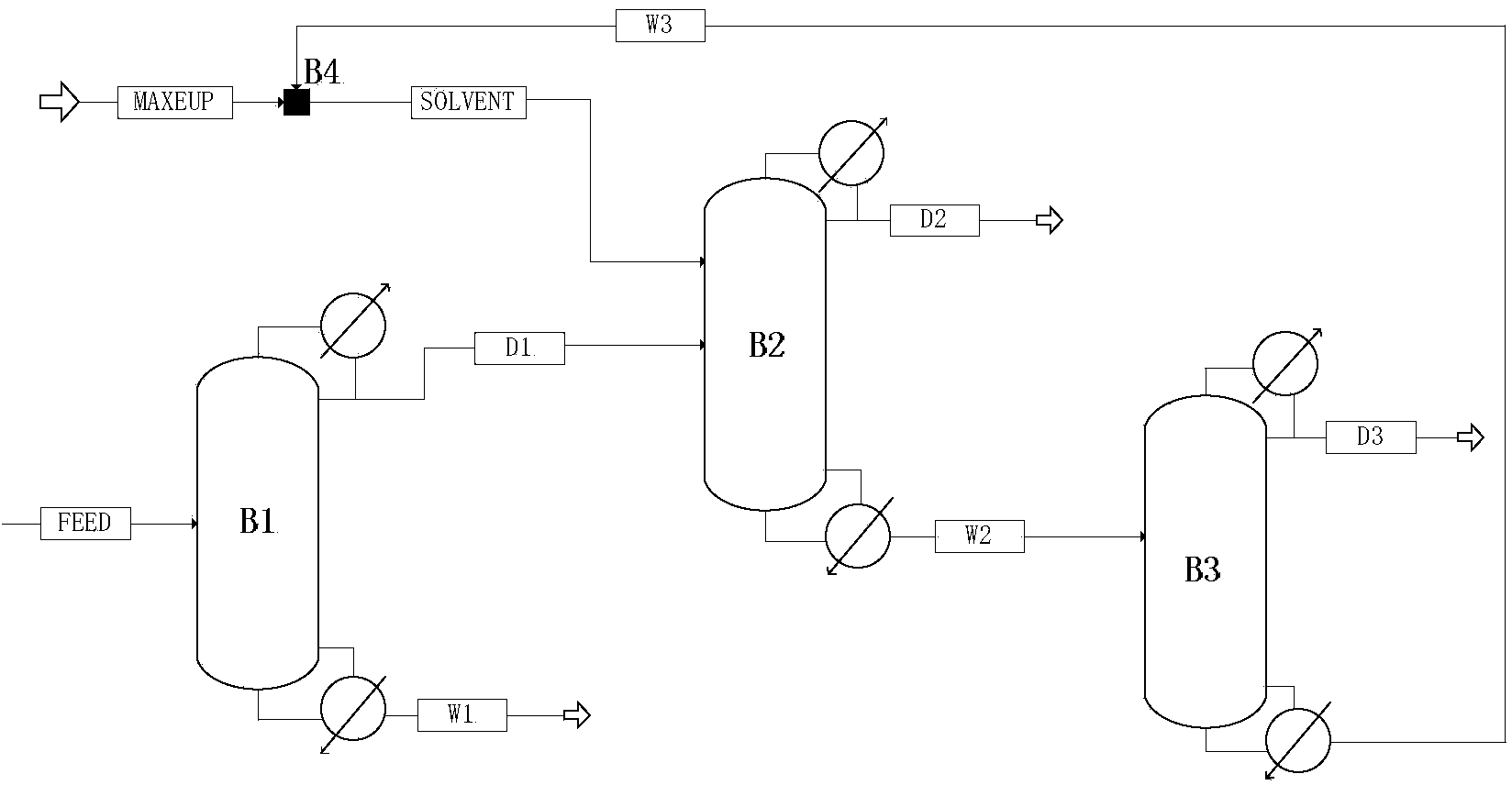

[0020] Such as figure 1 Shown: 40000kg / h of C8 aromatic hydrocarbon mixture material (containing ethylbenzene 6000kg / h, o-xylene 8000kg / h, m-xylene 18000kg / h, p-xylene 8000kg / h) enters the rectifying tower (B1), the tower The number of plates is 200, the reflux ratio is 8, 7920kg / h of o-xylene with a mass purity of 99.00% is obtained at the bottom of the tower, and the mixture of ethylbenzene, m-xylene and p-xylene at the top of the tower is 32080kg / h. Rectification tower (B1) overhead distillate enters extractive distillation tower (B2) separation, introduces extractant ethyl phenylacetate (32080kg / h) through mixer (B4) at extractive distillation tower (B2) simultaneously, the The number of trays is 255, the reflux ratio is 61, 5940kg / h of ethylbenzene with a mass purity of 99.23% is obtained at the top of the tower, and the mixture of ethyl phenylacetate, m-xylene and p-xylene at the bottom of the tower is 58220kg / h. The distillate at the bottom of the extractive distillati...

Embodiment 2

[0022] 50000kg / h of C8 aromatic hydrocarbon mixture material (containing ethylbenzene 7500kg / h, o-xylene 10000kg / h, m-xylene 22500kg / h, p-xylene 10000kg / h) enters the rectification column (B1), and the number of trays is 120 , reflux ratio 11, 9920kg / h quality purity is 99.20% o-xylene at the bottom of the tower, and 40080kg / h ethylbenzene, m-xylene, p-xylene mixture at the top of the tower. Rectification tower (B1) overhead distillate enters extractive rectification tower (B2) separation, introduces extraction agent methyl oleate (23358kg / h) at extractive rectification tower (B2) simultaneously, and this tower tray number 255, With a reflux ratio of 59, 7437kg / h of ethylbenzene with a mass purity of 99.12% is obtained at the top of the tower, and a mixture of 56001kg / h of propiophenone, m-xylene and p-xylene at the bottom of the tower. The distillate at the bottom of the extractive distillation tower (B2) enters the extractant recovery tower (B3). The number of plates in this...

Embodiment 3

[0024] 45000kg / h of C8 aromatic hydrocarbon mixture material (containing ethylbenzene 6750kg / h, ortho-xylene 9000kg / h, m-xylene 20250kg / h, p-xylene 9000kg / h) enters the rectifying tower (B1), and the number of trays in this tower 120, reflux ratio 13, 9000kg / h o-xylene with a mass purity of 99.49% can be obtained at the bottom of the tower, and 36000kg / h mixture of ethylbenzene, m-xylene and p-xylene at the top of the tower. The distillation column (B1) overhead distillate enters the extractive distillation column (B2) for separation, and introduces the extractant benzaldehyde (72000kg / h) in the extractive distillation column (B2) simultaneously, and the plate number of this column is 240, and the reflux ratio 65, 6691kg / h of ethylbenzene with a mass purity of 99.91% was obtained at the top of the tower, and 101309kg / h of benzaldehyde, m-xylene, and p-xylene mixture at the bottom of the tower. Extractive distillation tower (B2) tower bottom distillate enters extractant recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com