Vertical processing method and device for large-aperture high-steep space optical aspheric mirror

A technology of space optics and processing equipment, which is applied in the field of vertical processing of large-diameter and high-steep space optics aspheric mirrors. It can solve the problems of low precision, high cost, and low processing efficiency, and achieve high flexibility and reduce processing costs. , the effect of reducing the use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

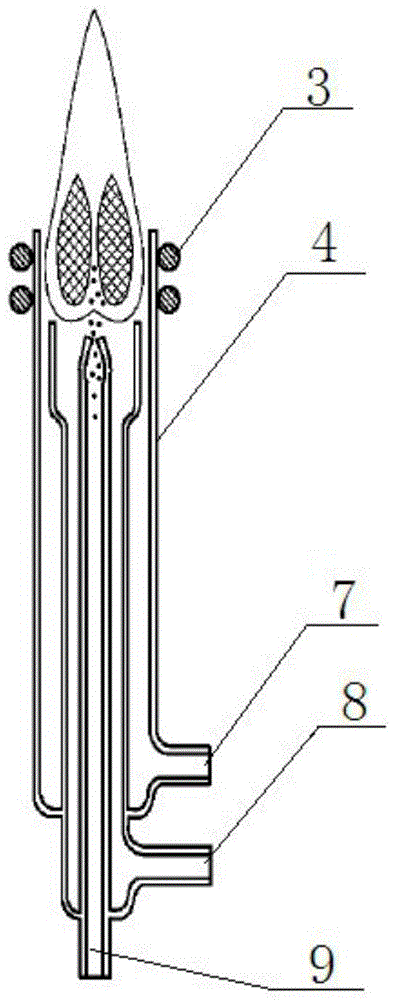

[0043] Such as figure 1 As shown, the vertical processing device for large-diameter and high-steep space optical aspheric mirrors of the present invention includes a mechanical arm 11 , an inductively coupled plasma generator, a protective cover 10 , a cooling circulation pump 5 and an air source 6 . The protective cover 10 is made of stainless steel. The inductively coupled plasma generator is installed inside the protective cover 10 as a whole, and then the protective cover 10 and the inductively coupled plasma generator are installed on the load end of the mechanical arm 11. The protective cover 10 is used to prevent the electromagnetic radiation leakage of the inductively coupled plasma generator. The protective cover The specific size of 10 can be flexibly adjusted as required. exist figure 1 In the figure, the cooling circulation pump 5, the air sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com