Fluidized bed technology for processing and separating ultrafine silicon dioxide micropowder from stone processing sawn mud

A technology of ultra-fine silica and fluidized bed, applied in the direction of silica, silicon oxide, etc., can solve the problem of high price of white carbon black, achieve the effect of low price, eliminate pollution, and avoid dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

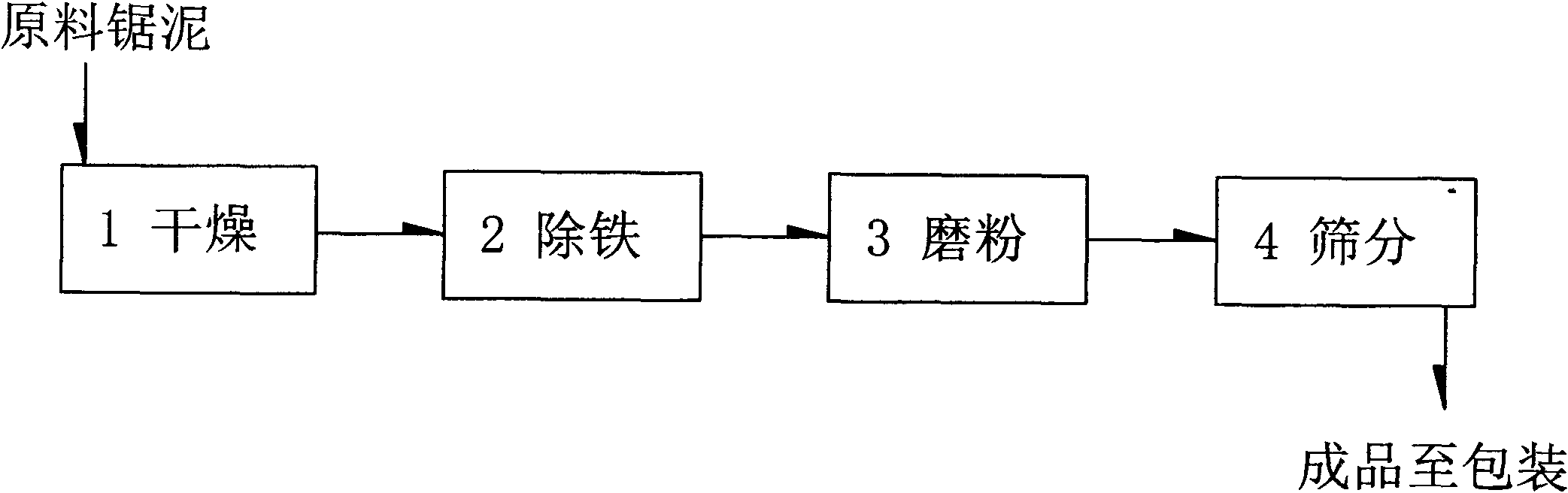

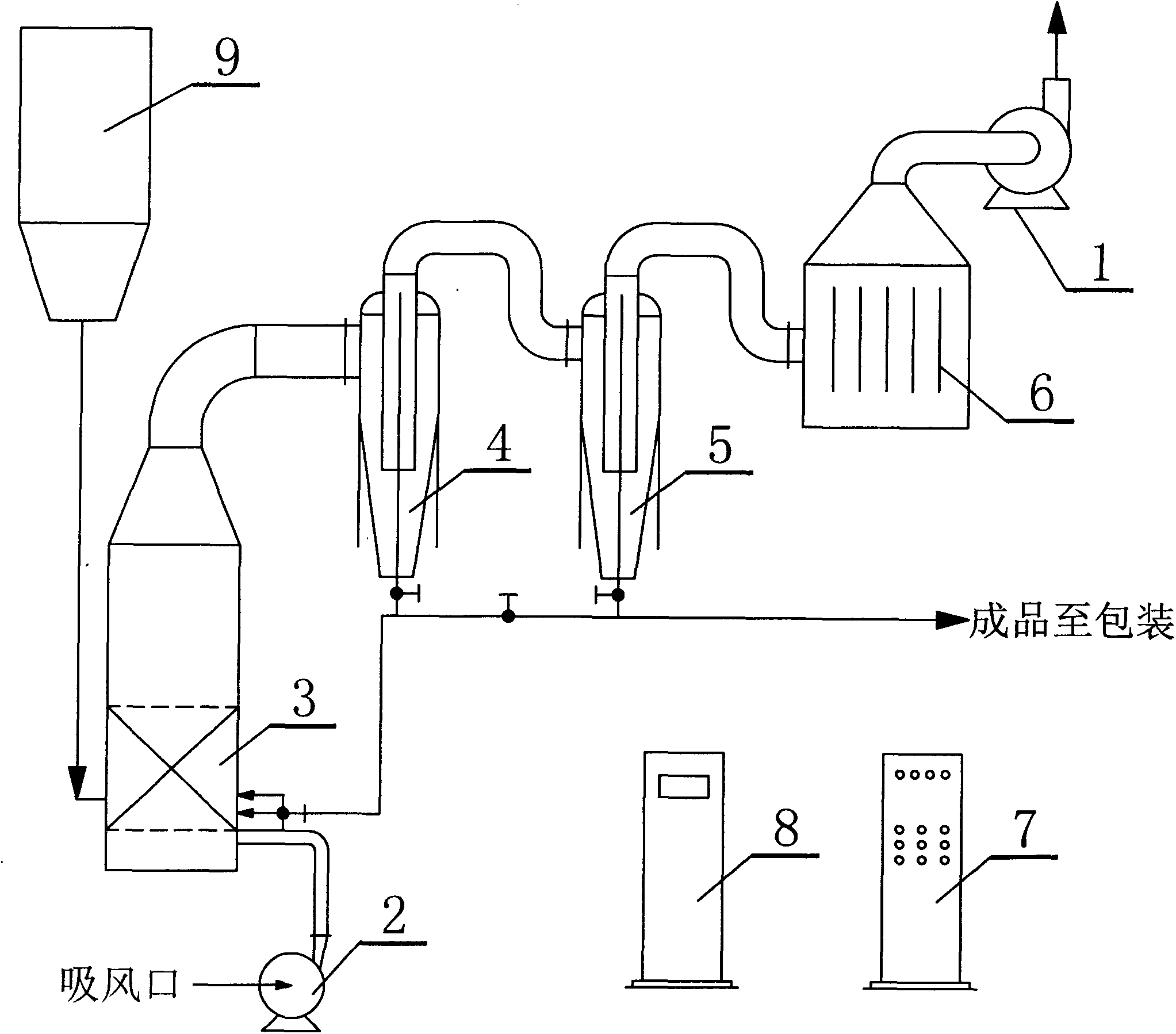

[0020] The process route selected by the patent of the present invention is: 1. Drying of sawing mud, 2. Iron removal by strong magnetic field, 3. Ultra-fine grinding, 4. Fluidized bed screening, a total of four process units. The process route is attached figure 1 .

[0021] 1 Saw slime drying unit. In order to make the operation of the following three process units go smoothly, the moisture content of the raw materials must be reduced from 12 to 15% to below 3%, and the drying unit adopts far-infrared forced exhaust continuous drying equipment;

[0022] 2 Strong magnetic field iron removal unit. Under the action of a strong electromagnetic field, a small amount of metal impurities in the raw material (about 2-3% mainly come from tool wear) is removed to meet the requirements of the products in terms of electrical insulation performance when the product is used as a reinforcing agent in rubber, plastic, glass fiber reinforced plastic and other products;

[0023] 3 Superfi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com