Preparation method and device for rapidly-activated active coke

An active coke and fast technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of long production time, shorten production time, and reduce production cost of desulfurization and denitration activated coke, and achieve good market application prospects, Reasonable design and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

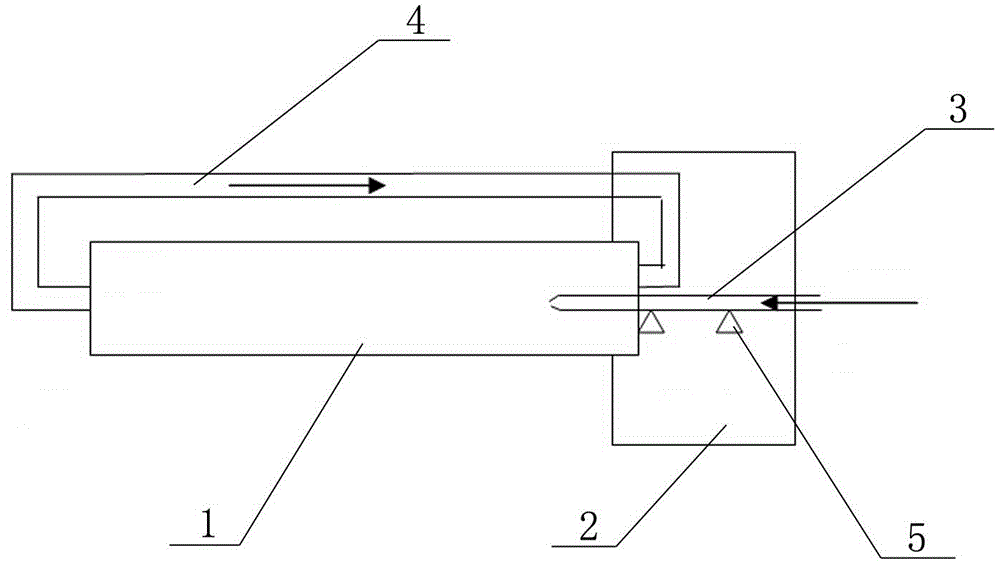

[0016] A method for rapidly activating active coke. First, the following improvements are made to the existing carbonization rotary furnace: a. A steam pipe is added in the furnace. DN15, the stainless steel pipe is inserted from the combustion chamber of the furnace head to the discharge port of the furnace head, and is supported by 2 points of 310S angle iron in the middle; The combustible substances released by the low-temperature dry distillation are transported to the furnace head for combustion, so that the carbonization temperature of the raw material at the furnace head is raised from 650°C to 850°C; Transport to the outlet of the furnace head to activate the raw materials. The activation time is 14, 15, 16, 17 or 18 minutes, and then the materials can be discharged.

[0017] Such as figure 1 As shown, the above-mentioned rotary kiln...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com