Preparation equipment and method of insulating pull rod for circuit breaker

A technology for insulating pull rods and circuit breakers, which is applied in the preparation equipment and field of insulating pull rods for circuit breakers. It can solve problems such as inhomogeneity, affecting the high voltage resistance of products, and poor surface finish of finished products, so as to reduce air bubbles and ensure mechanical and electrical integrity. Performance, the overall uniform effect of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

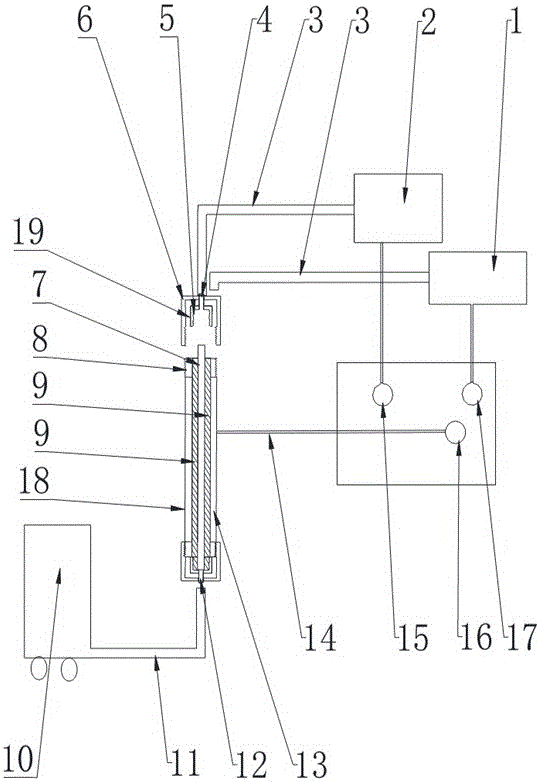

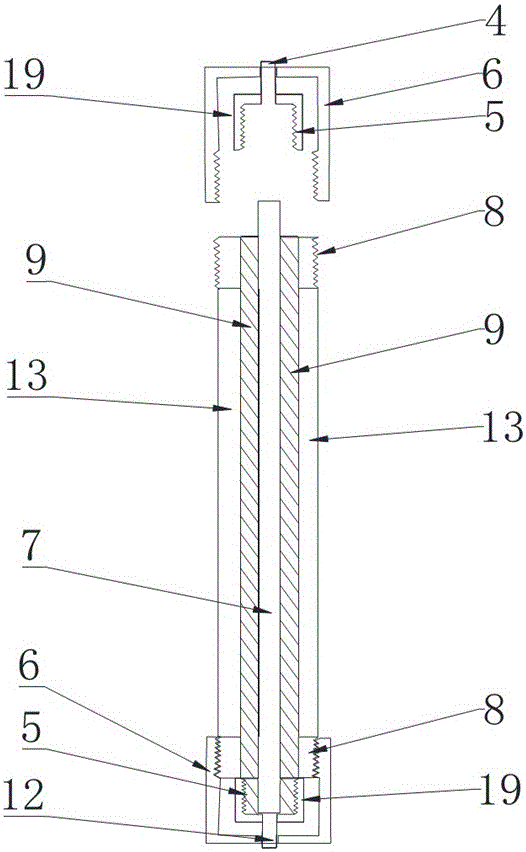

[0035]The technical solution adopted by the present invention is the preparation equipment for insulating pull rods for circuit breakers, including a mold 18, a control console and a resin treatment device 10 for pretreating the resin. The mold 18 is provided with a vertically arranged cylindrical mandrel 7, and the mandrel 7 The outer circumference is sleeved with a circular heat-insulating sleeve 13, which is used as the outer mold of the mold 18. The axis of the heat-insulating sleeve 13 coincides with the mandrel 7, and the ring between the heat-insulating sleeve 13 and the mandrel 7 The shaped cavity is an inner cavity 9 for preparing an insulating pull rod; the upper and lower circumferential outer surfaces of the heat insulating sleeve 13 are provided with connecting threads 8, and the top and bottom of the mandrel 7 are respectively provided with an end sealing flange 6, The circumferential inner wall of the end-sealing flange 6 is provided with a thread that is sealing...

Embodiment 2

[0038] Use the preparation equipment described in embodiment 1 to prepare the method for the insulation pull rod of circuit breaker, the steps of this preparation method are:

[0039] (1) Mold preparation: first clean the surface of the inner cavity of the mold, the outer surface of the mandrel and the end seal flange and apply a release agent, then roll the carbon fiber cloth on the mandrel flatly, and when the mandrel When the diameter of the carbon fiber cloth on the top is rolled to the size of the inner diameter of the heat insulation sleeve, the carbon fiber cloth is cut; the mandrel wrapped around the carbon fiber cloth is put into the inside of the heat insulation sleeve, and the sealing gasket is placed in the end sealing flange, and then the end sealing flange is placed. The sealing flange and the heating sleeve are tightly sealed, and the heating knob is adjusted to heat the mold to 130°C;

[0040] (2) Mold vacuuming: adjust the air valve and vacuum control knob, co...

Embodiment 3

[0046] Use the preparation equipment described in embodiment 1 to prepare the method for the insulation pull rod of circuit breaker, the steps of this preparation method are:

[0047] (1) Mold preparation: first clean the surface of the inner cavity of the mold, the outer surface of the mandrel and the end seal flange and apply a release agent, then roll the carbon fiber cloth on the mandrel flatly, and when the mandrel When the diameter of the carbon fiber cloth on the top is rolled to the size of the inner diameter of the heat insulation sleeve, the carbon fiber cloth is cut; the mandrel wrapped around the carbon fiber cloth is placed inside the heat insulation sleeve, and the sealing gasket is placed in the end seal flange. , Tighten and seal the end seal flange with the heating jacket, adjust the heating knob to heat the mold to 180°C;

[0048] (2) Mold vacuuming: adjust the air valve and vacuum control knob, control the vacuum pump to vacuum the inner cavity, and the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com