Preparation method of self-supporting two-dimensional transition metal/metal oxide mixed-phase nanosheet

A transition metal and oxide technology, applied in the field of preparation of two-dimensional nanomaterials, can solve the problems of harsh reaction conditions, complex processes, poor conductivity of transition metal oxides, etc., and achieves good reproducibility, simple preparation process, and easy commercialization. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Embodiment 1: The preparation method of self-supporting two-dimensional transition metal / metal oxide mixed-phase nanosheets in this embodiment is implemented according to the following steps:

[0024] 1. Mix the transition metal inorganic salt and water to prepare an inorganic salt aqueous solution with a molar concentration of 0.025 to 0.1 mol / L, and add organic amine and alcohol in sequence at 25°C under stirring conditions to make the molar concentration of the transition metal inorganic salt and organic amine The ratio is 1:3~15, the volume ratio of water and alcohol is 1:1~3, continue to stir evenly to obtain the turbid liquid of organic amine complex containing metal ions;

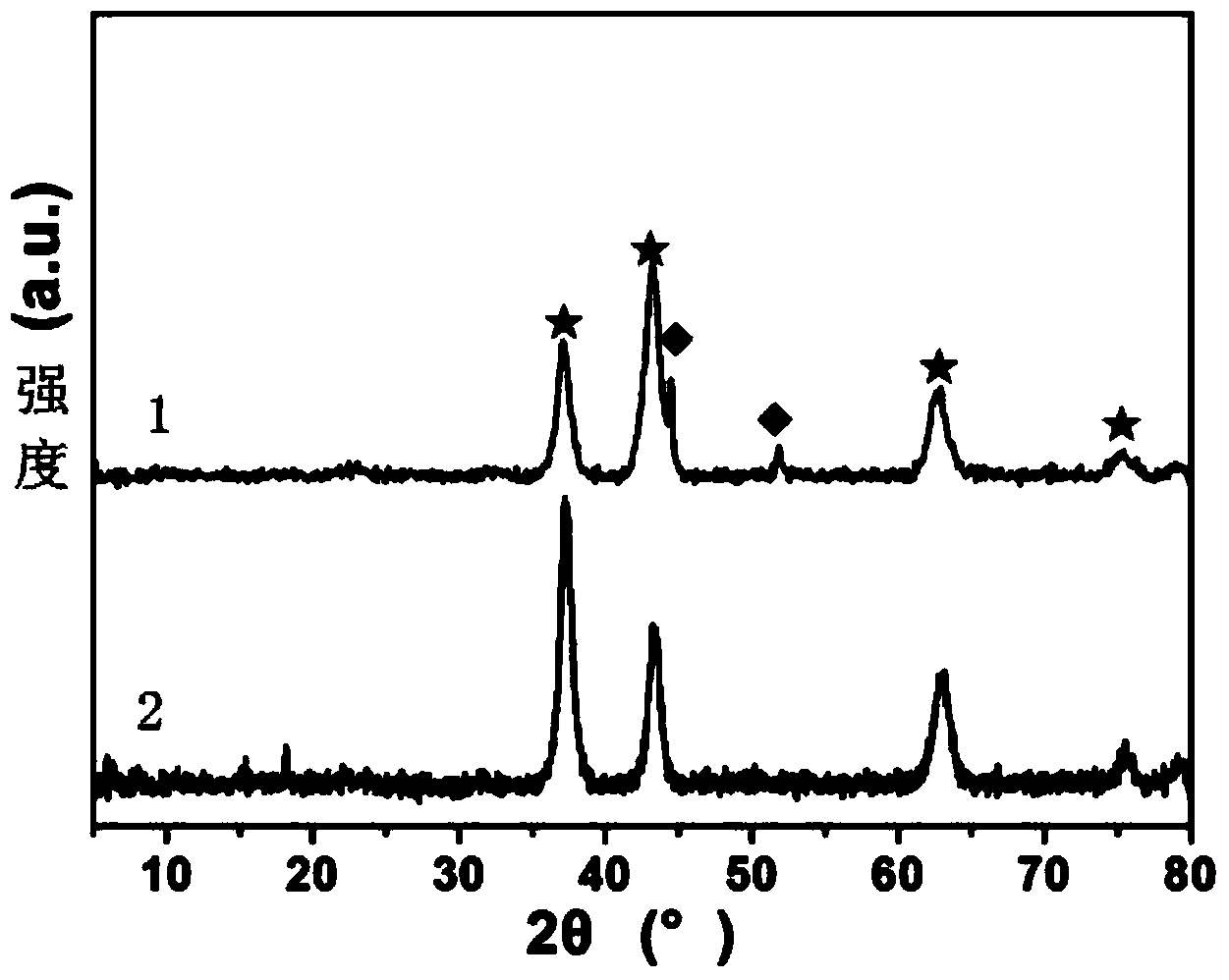

[0025] 2. Transfer the turbid liquid of the organic amine complex containing metal ions obtained in step 1 to a high-pressure reactor, conduct a solvothermal reaction at 120-200°C for 6-24 hours, cool to 25°C, and then separate the reactants, After washing, it is dried in an oven to obtain the...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 in that step 1 sequentially adds organic amine and alcohol under stirring conditions at 25° C., wherein the stirring speed is 100-1000 r / min. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the transition metal inorganic salt is mixed with water to prepare an aqueous inorganic salt solution with a molar concentration of 0.05-0.10 mol / L. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com