Shaoyang cold treatment granules and preparation method for same

A technology of granules and traditional Chinese medicine, applied in the field of Shaoyang Ganmao Granules and its preparation, can solve the problems of unsatisfactory curative effect and low curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

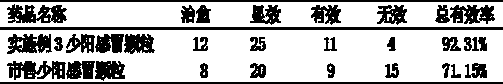

Examples

Embodiment 1

[0031] Take 80g of Allium scallions, 28g of Xia Wu, 206g of Scutellaria baicalensis, 206g of pinellia, 138g of dried ginger, 138g of jujube, 69g of ginseng, 206g of Artemisia annua, grind them into 40 mesh coarse powder, put them in a circulating ultrasonic extractor, add 10710g of water, 4g of germanium Powder, 6g Tween 60, select ultrasonic frequency 50KHz, extract with pressure 0.3Mpa for 30 minutes, filter with 80 mesh sieve to obtain extract; take extract and put it in a jet spray dryer, control the inlet air temperature at 40°C, pressure 0.02Mpa, The flow rate is 400 meters per second to obtain nano-extract powder; take the extract powder, add 400g of lactose and 100g of dextrin, wet granulate with water, dry at 60°C, granulate, add 15g of talcum powder, mix well, and prepare Shaoyang Ganmao Granules.

specific Embodiment 2

[0033] Take 80g of Allium scallions, 28g of Xia Wu, 206g of Scutellaria baicalensis, 206g of pinellia, 138g of dried ginger, 138g of jujube, 69g of ginseng, 206g of Artemisia annua, grind them into 40 mesh coarse powder, put them in a circulating ultrasonic extractor, add 10710g of water, 6g of germanium Powder, 8g Tween 60, select ultrasonic frequency 60KHz, extract at a pressure of 0.5 Mpa for 30 minutes, filter with an 80-mesh sieve to obtain the extract; take the extract and put it in a jet spray dryer, control the inlet air temperature at 50°C, and the pressure at 0.04 Mpa, The flow velocity is 600 meters per second to obtain nano-extract powder; take the extract powder, add 400g of lactose and 100g of dextrin, wet granulate with water, dry at 60°C, granulate, add 15g of talcum powder, mix well, and prepare Shaoyang Ganmao Granules.

Embodiment 3

[0035] Take 80g of Scallion, 28g of Xia Wu, 206g of Scutellaria baicalensis, 206g of pinellia, 138g of dried ginger, 138g of jujube, 69g of ginseng, 206g of Artemisia annua, grind them into 40 mesh coarse powder, put them in a circulating ultrasonic extractor, add 10710g of water, 5g of germanium Powder, 7g Tween 60, select ultrasonic frequency 55KHz, extract at pressure 0.4Mpa for 30 minutes, filter with 80 mesh sieve to obtain extract; take extract and put it in jet spray dryer, control air inlet temperature at 45°C, pressure at 0.03Mpa, The flow velocity is 500 meters per second to obtain nano-extract powder; take the extract powder, add 400g of lactose and 100g of dextrin, wet granulate with water, dry at 60°C, granulate, add 15g of talcum powder, mix well, and prepare Shaoyang Ganmao Granules.

[0036] The above examples illustrate that Shaoyang Ganmao Granules can be made by adopting the extreme conditions and optimized conditions of the embodiments of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com