A countercurrent inoculation device and inoculation method in solid fermentation

A solid fermentation and countercurrent technology, applied in feed, food science, application, etc., can solve the problems of difficult and thorough cleaning of materials, uneven inoculation, low inoculation production efficiency, etc., to facilitate cleaning and maintenance, and improve inoculation efficiency , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

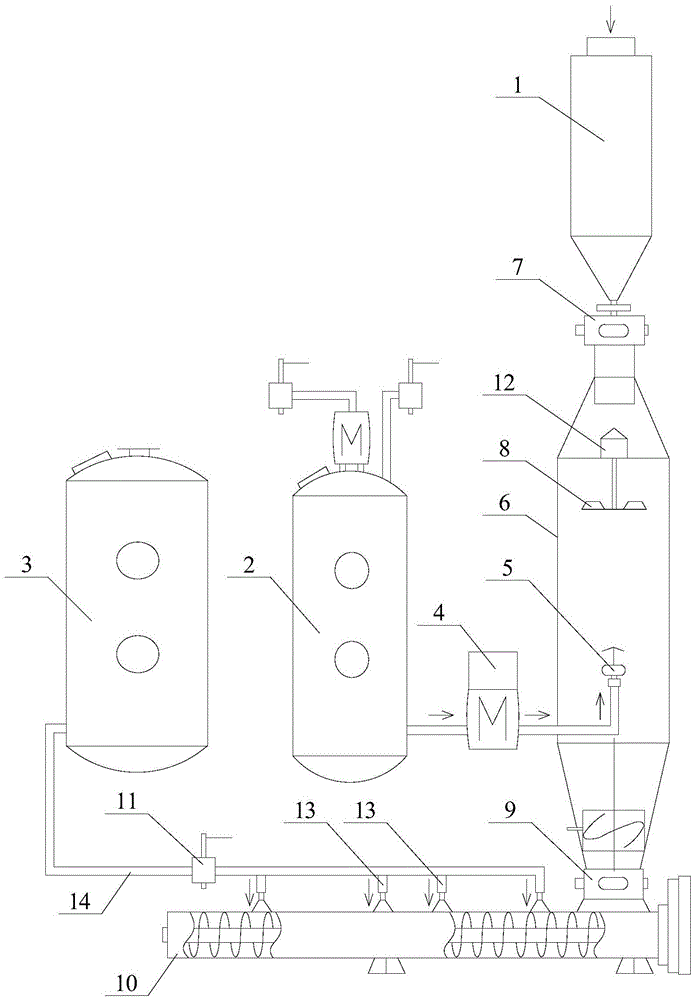

[0021] Such as figure 1 As shown, a countercurrent inoculation device in solid fermentation involved in this embodiment includes: a storage bin 1, a strain dilution activation tank 2, a nutrient solution adjustment tank 3, a plunger pump 4, a bacteria liquid nozzle 5, Bacteria tower 6, feeder 7, bulk material blade 8, stirring and oscillating feeder 9, stirring and conveying auger 10, nutrient regulating liquid control valve 11, bulk material blade motor 12, nutrient regulating liquid nozzle 13 and nutrient regulating liquid pipe Road 14. Described waiting bin 1 is arranged on the top of inoculating tower 6, and waiting bin 1 is connected with inoculating tower 6, and the lower end of waiting bin 1 is provided with feeder 7, and the outlet of described feeding device 7 is connected with The feeding port of the bacteria-connecting tower 6 corresponds up and down, and the feeding port of the bacteria-connecting tower 6 is equipped with a bulk material blade motor 12, and the bu...

Embodiment 2

[0031] This embodiment is a method of countercurrent inoculation in solid fermentation. The steps are as follows: 1. Preparation of solid fermentation materials: the solid fermentation materials are removed from impurities, iron and sieved. After mixing evenly, they are crushed and transported to Stand-by in bin 1; 2. Preparation of the bacteria solution to be inoculated: transport the stock solution of the bacteria to be inoculated to a strain dilution and activation tank at a constant temperature of 37°C and add the diluted nutrient solution, and stir evenly for use; 3. The nutrient adjustment solution Preparation: transport the nutrient adjustment liquid used for fermentation to the nutrient liquid adjustment tank 3 for use; 4. Equipment inspection and control adjustment setting: set the spraying amount of the bacterial liquid according to 2% of the weight of the solid fermentation material, press 35% of the weight of the solid fermentation material is used to set the amount...

Embodiment 3

[0033] The countercurrent inoculation method in soybean meal solid fermentation, the steps are as follows: 1. Fermentation material preparation: remove impurities, iron and sieve high-protein soybean meal (protein content greater than 45%) and fermentation auxiliary materials, mix them evenly, and press the process particle size to 40 mesh Requirements, crushed and transported to the waiting bin 1 for use; 2. Preparation of the bacteria solution to be inoculated: transport the original solution of the bacteria to be inoculated GY15 soybean meal to the 37°C constant temperature strain dilution activation tank and add the special bacteria at a ratio of 1:10 Dilute the nutrient solution and stir it evenly for use; 3. Preparation of nutrient adjustment solution: transport the nutrient adjustment solution used for soybean meal fermentation to the nutrient solution adjustment tank 3 according to the composition ratio and mix it for use; 4. Equipment inspection and control adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com