Two-stage arc plasma torch

An arc plasma and plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problems of incomplete decomposition and low heating efficiency, and achieve the effect of improving heating efficiency, heating efficiency and decomposition ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

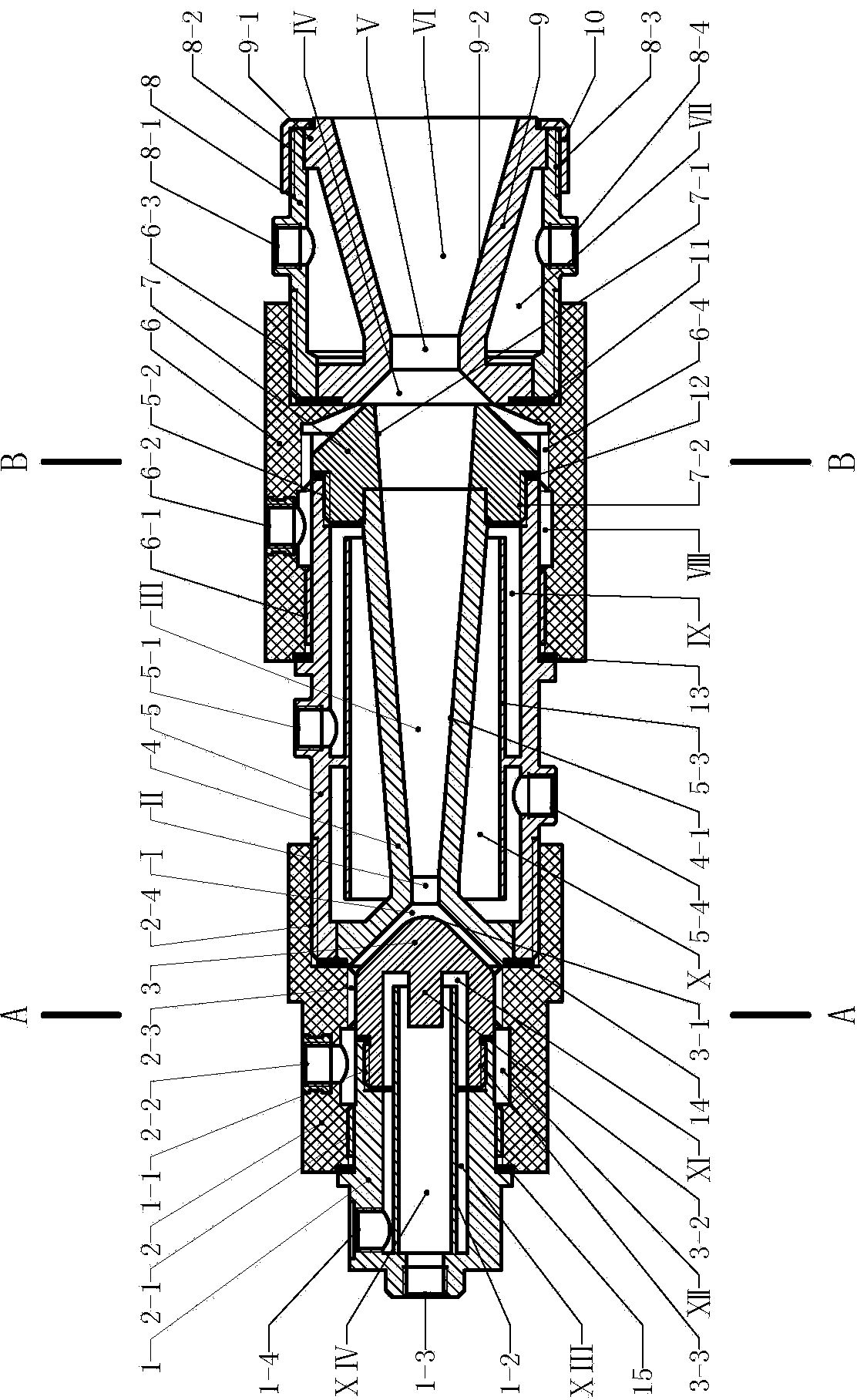

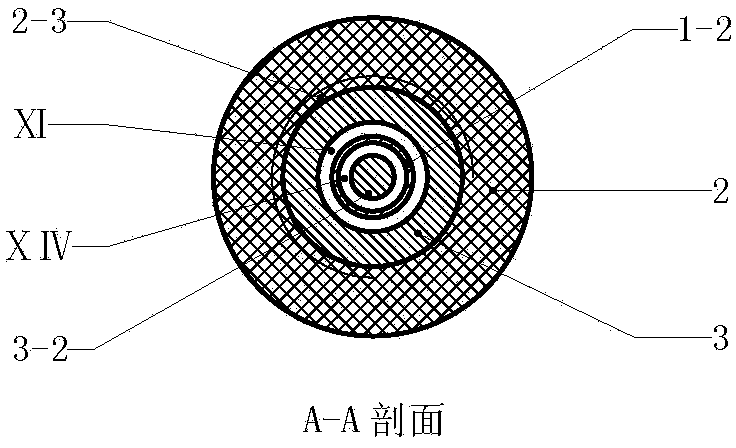

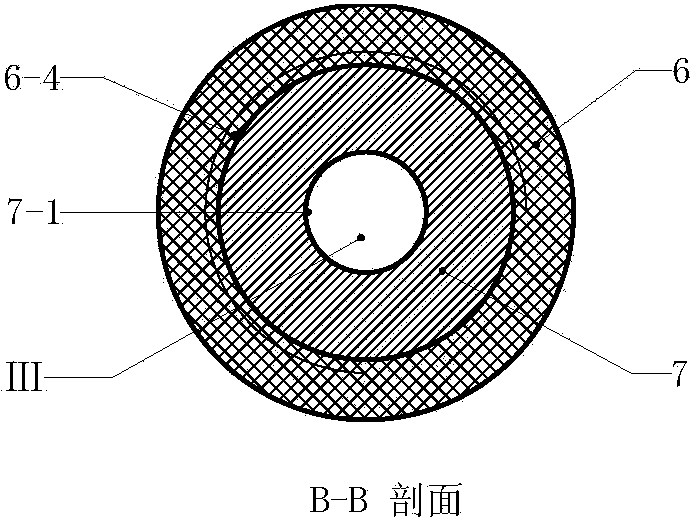

[0016] Example 1 figure 1 In the illustrated embodiment, the dual-stage arc plasma torch consists of a back seat (1), a first cathode (3), a first insulating gun holder (2), a first anode (4), a second cathode (7), The first pipe sleeve (5), the second insulating gun holder (6), the second anode (9) and the second pipe sleeve (8), wherein, the rear seat (1) is a rotary structure, and the rear seat (1) ) has a cooling water circuit, and there is a mounting screw (1-1) at the front end of the center of the revolving body of the rear seat (1), and there is a guide tube (1-2) in the cooling water circuit of the rear seat (1). The flow tube (1-2) extends into the cooling cavity (Ⅺ) of the first cathode (3), the space inside the tube of the flow guide tube (1-2) forms a cooling water supply channel (XIV), and the flow guide tube (1-2 ) The space outside the pipe constitutes the cooling water return channel (ⅩⅢ), the cooling water supply channel (ⅩⅣ) is connected to the cooling wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com