Method for improving yield of patterning sapphire substrate

A patterned sapphire, yield rate technology, applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as low cost, uneven surface, etc., and achieve the requirements of characteristics and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

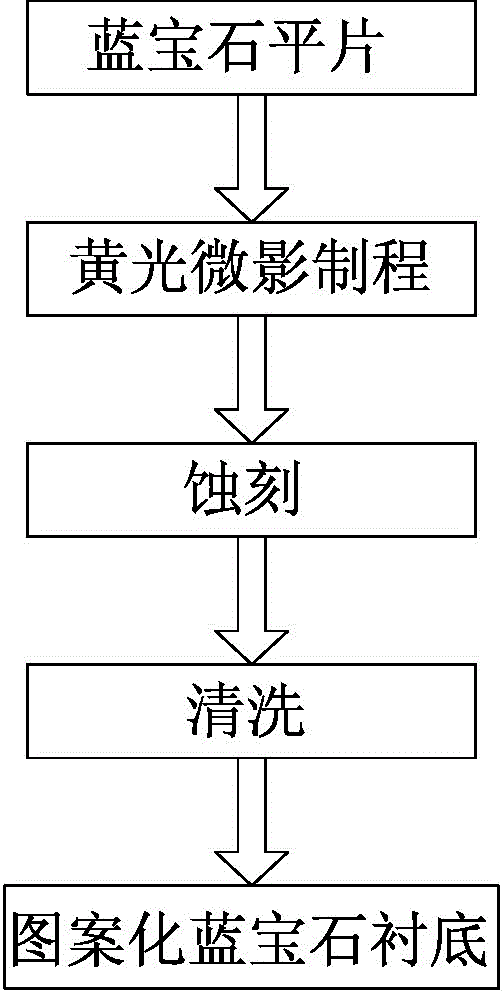

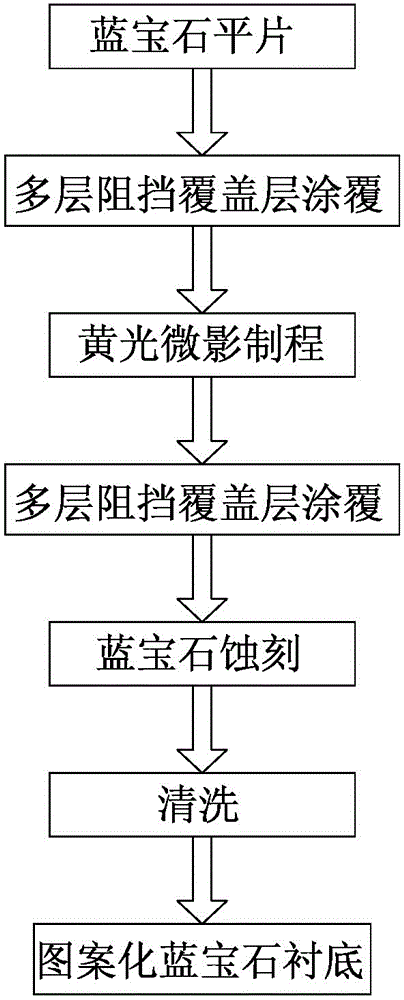

[0018] Such as figure 2 and image 3 As shown, the present invention discloses a method for improving the yield rate of a patterned sapphire substrate, the steps of which are as follows.

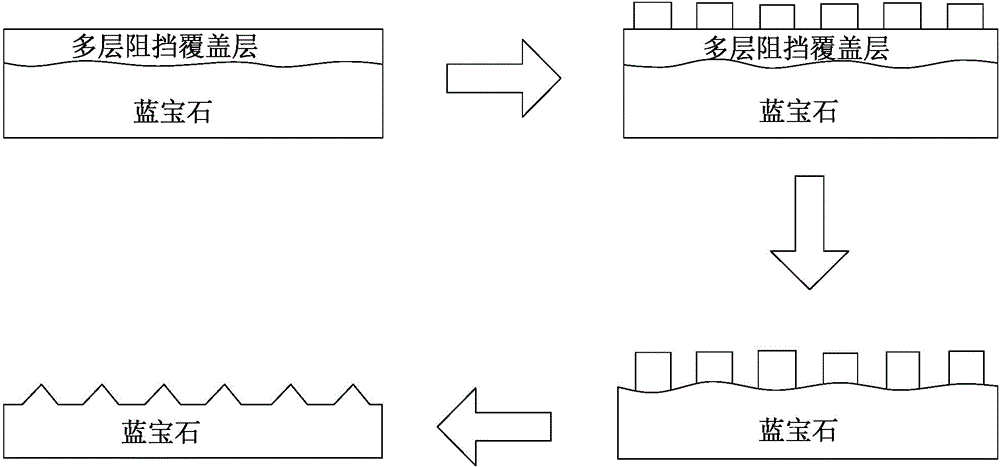

[0019] The first step is to apply multi-layer barrier layer coating on sapphire; because the surface of the existing sapphire substrate has curvature, especially local unevenness, after the multi-layer barrier layer coating is completed, the top surface of the cover layer is flat, which can be carried out smoothly The conventional yellow light lithography process.

[0020] The multi-layer barrier layer is coated with a three-layer structure. The bottom layer is a thicker layer, which can fill up the undulating structure and create conditions for the effectiveness of the photoresist lithography process on the top layer. The bottom layer material is generally non-photoresist containing C, H , O polymers, such as organic bottom anti-reflective coating Organic BARC, and act as a shield for tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com