A metal stress corrosion test device in a crevice

A technology of corrosion experiment and metal stress, applied in the field of corrosion experiment technology and measurement, it can solve the problems that stress corrosion cannot be studied and cannot be applied, and achieve the effect of simple structure, convenient operation and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

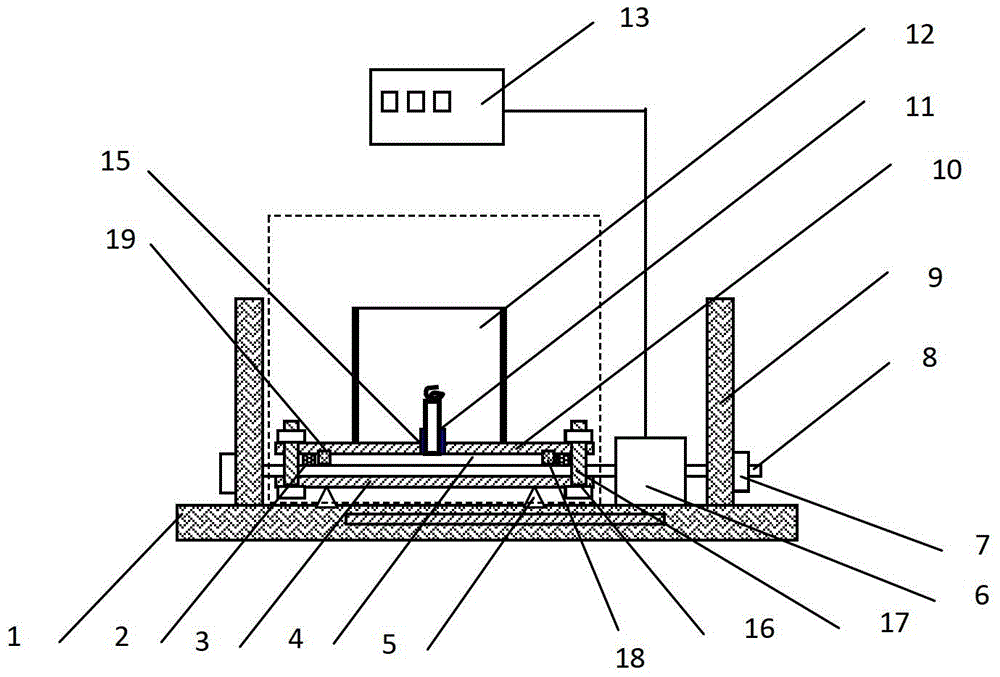

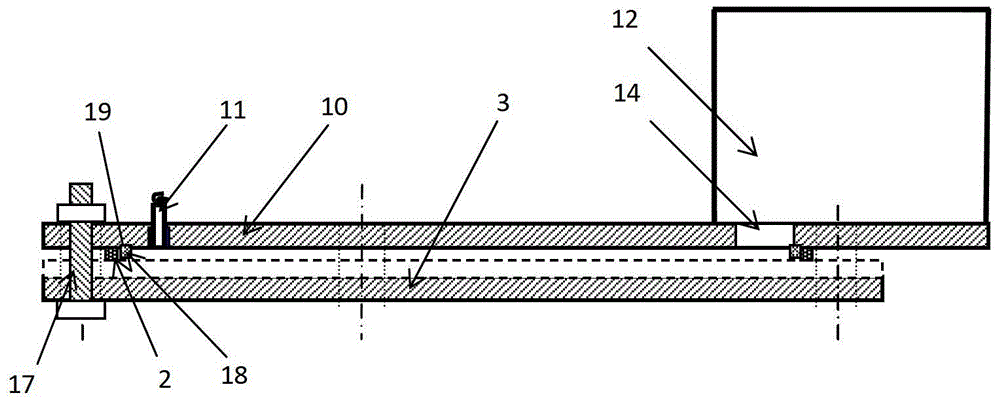

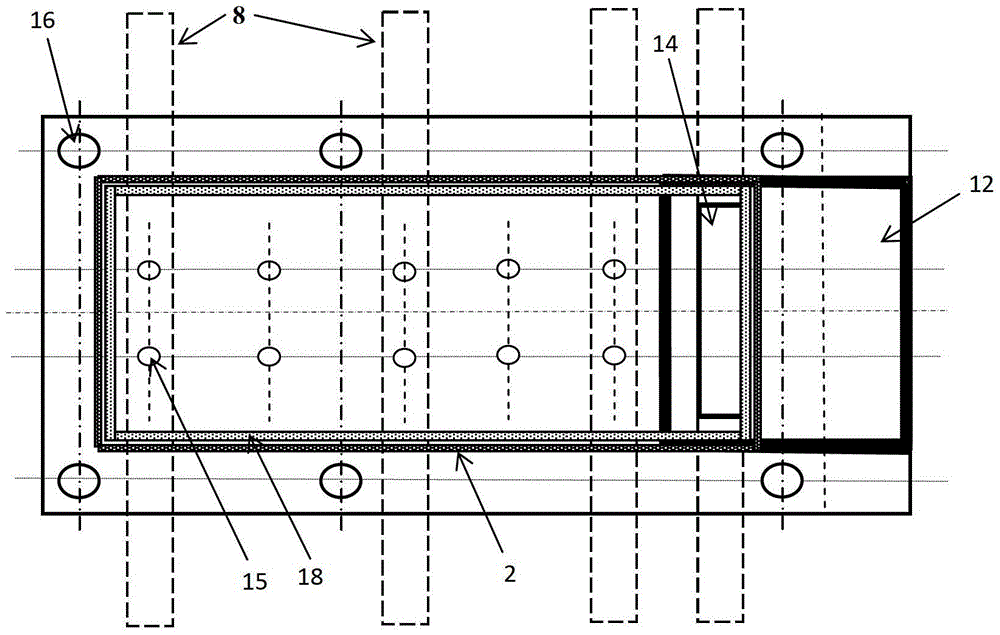

[0019] Such as figure 1 , as shown in Figure 2(a) and Figure 2(b), the experimental device for metal stress corrosion corrosion in the crevice of the present invention mainly includes: a booster support base 1, a positioning gasket 2, a crevice pool base 3, a crevice pool 4, and a crevice pool support 5. Load measuring sensor 6, loading nut 7, tensile sample 8, force support plate 9, gap pool cover 10, microelectrode 11, bulk solution pool 12, load display 13, gap opening 14, microelectrode jack 15. Fixing hole 16, fixing piece 17, O-ring 18, etc. The specific structure is as follows:

[0020] Such as figure 1 As shown, on the booster support base 1, the booster support plate 9 is arranged in parallel, and the tensile sample 8 is installed between the parallel booster support plates 9, and the tensile sample 8 passing through the gap pool 4 stretche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com