Integrated detection structure of vortex flowmeter

A vortex flowmeter and integrated detection technology, which is applied in the direction of volume/mass flow, volume change compensation/correction device, etc. by detecting the dynamic effect and mechanical effect of fluid flow, can solve the problems of increasing fluid leakage and increasing processing Problems such as process, time, and drilling accuracy are difficult to grasp, so as to achieve the effect of simplifying structural design, preventing mutual interference, and ensuring normal and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

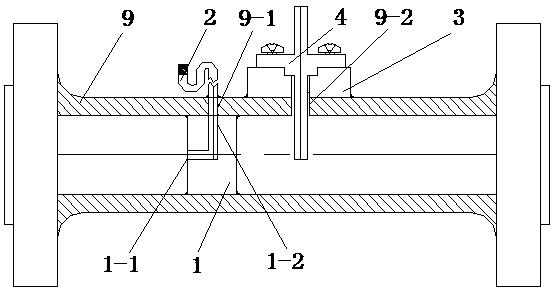

[0013] Such as Figure 1 to Figure 3 As shown, an integrated detection structure of a vortex flowmeter includes a vortex flowmeter casing 9 connected to a pipeline, and also includes a sounding body 1, an S-shaped tube 2, a probe fixing member 3, a probe 4, a temperature connecting line 5, Flow detector 6 temperature detector 7, filler 8.

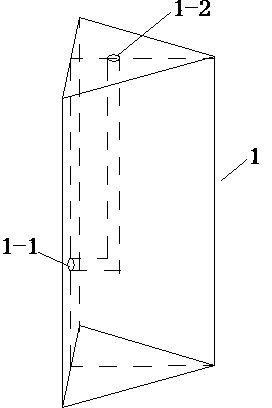

[0014] The sounding body 1 is a triangular shape, with an air inlet 1-1 on the side wall of the sounding body 1, and an air outlet 1-2 on the top of the sounding body 1, and the air outlet 1-2 is located at the center of gravity of the top end surface of the sounding body 1 , the air inlet 1-1 and the air outlet 1-2 form an L-shaped pressure guiding channel.

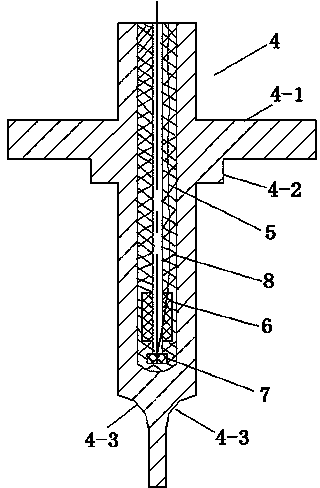

[0015] The probe 4 is a cylindrical body with an inner cavity, the upper end of the probe 4 is provided with a circular flange 4-1, the lower part of the circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com