Method for preparing monodisperse size-controllable nanosilver particles by using radio frequency magnetron sputtering method

A radio frequency magnetron sputtering, nano silver particle technology, applied in nanotechnology, sputtering plating, ion implantation plating and other directions, can solve the problem of large dispersion of nanoparticles, poor directional growth of nanoparticles, particle shape and particle size distribution Non-uniformity and other problems, to achieve the effect of small deposition rate, uniform and tidy particles, and easy growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

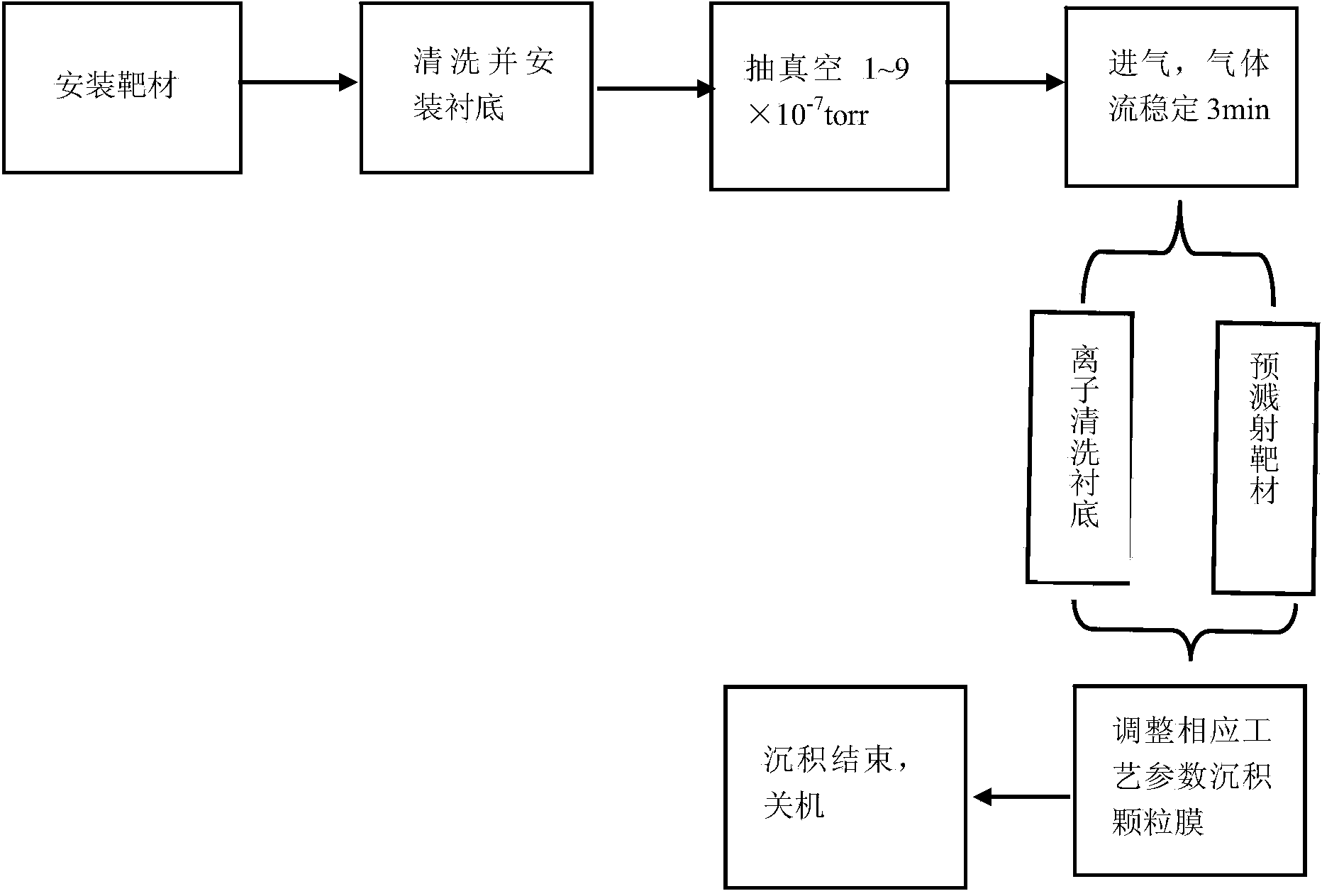

[0028] The purpose of this embodiment is to prepare monodisperse nano silver particles with a particle size of about 5 nanometers on a glass substrate by radio frequency magnetron sputtering. The process for preparing nano silver particle films by radio frequency magnetron sputtering is as follows figure 1 As shown, the preparation method specifically includes the following steps:

[0029] (1) Select 99.999% ultra-pure silver as the target material for magnetron sputtering, and put it into the magnetron sputtering chamber;

[0030] (2) Using glass as the substrate, ultrasonically clean the glass substrate with deionized water, acetone and isopropanol in sequence for 10 min, rinse thoroughly with deionized water, blow dry with nitrogen, and install it on the substrate table;

[0031] (3) Close the sputtering chamber and evacuate to 1×10 -7 ~9×10 -7 torr, use high-purity argon as the working gas, adjust the air pressure to 13mtorr, turn on the power source under the substrate ...

Embodiment 2

[0035] The purpose of this embodiment is to prepare monodisperse nano-silver particles with a particle size of about 10 nanometers on a glass substrate by radio frequency magnetron sputtering. The process for preparing nano-silver particle films by radio frequency magnetron sputtering is as follows figure 1 As shown, the preparation method specifically includes the following steps:

[0036] (1) Select 99.999% ultra-pure silver as the target material for magnetron sputtering, and put it into the magnetron sputtering chamber;

[0037] (2) Using glass as the substrate, ultrasonically clean the glass substrate with deionized water, acetone and isopropanol in sequence for 10 min, rinse thoroughly with deionized water, blow dry with nitrogen, and install it on the substrate table;

[0038] (3) Close the sputtering chamber and evacuate to 1×10 -7 ~9×10 -7 torr, use high-purity argon as the working gas, adjust the air pressure to 10mtorr, turn on the power source under the substrate...

Embodiment 3

[0042] The purpose of this embodiment is to prepare monodisperse nano-silver particles with a particle size of about 30 nanometers on a glass substrate by radio frequency magnetron sputtering. The process for preparing nano-silver particle films by radio frequency magnetron sputtering is as follows figure 1 As shown, the preparation method specifically includes the following steps:

[0043] (1) Select 99.999% ultra-pure silver as the target material for magnetron sputtering, and put it into the magnetron sputtering chamber;

[0044] (2) Using glass as the substrate, ultrasonically clean the glass substrate with deionized water, acetone and isopropanol in sequence for 15 minutes, rinse thoroughly with deionized water, blow dry with nitrogen, and install it on the substrate stage;

[0045] (3) Close the sputtering chamber and evacuate to 1×10 -7 ~9×10 -7 torr, use high-purity argon as the working gas, adjust the air pressure to 13mtorr, turn on the power source under the subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com