Shell product end surface roundness vibration aging shape-correction device and shape-correction method

A technology of vibration aging and shape correction, which is applied in the field of vibration aging shape correction device for the roundness of the end face of shell products, which can solve the problems that the shell cannot be assembled and riveted, the welding stress is large, and the roundness of the end face of the shell is poor, so as to shorten the production time. and problem handling cycle, huge economic effect and social value, and the effect of guaranteeing external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

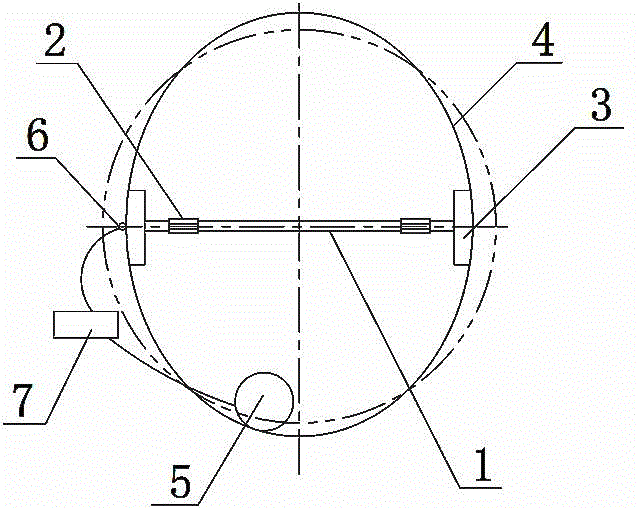

[0022] Such as figure 1 As shown, a shell product end face roundness vibration aging correction device, it includes a strut 1, an adjustment mechanism 2, a pressure block 3, a vibrator 5, a probe 6 and a measuring device 7, the two ends of the strut 1 are respectively There are briquetting blocks 3, and an adjusting mechanism 2 is arranged between each briquetting block 3 and the strut 1. The briquetting block 3 moves along the axial direction of the strut 1 under the regulation of the regulating mechanism 2, and the outer surface of the briquetting block 3 pushes Press on the inner wall of the housing 4 to be adjusted, the exciter 5 is placed on the inner wall of the housing 4 to be adjusted, the probe 6 is arranged on the outer wall of the housing 4 to be adjusted near the pressing block 3, and the measuring device 7 is respectively It is connected with probe 6 and vibrator 5 for control.

[0023] The pressing block 3 presses against the smallest diameter of the housing 4 t...

Embodiment 2

[0033] The structure of a device for correcting the roundness of the end face of a shell product through vibration and aging is the same as that in Embodiment 1.

[0034] A method for correcting the shape of a shell product end face roundness vibration aging correction device is adopted, which comprises the following steps:

[0035] S1, measure the diameter of the housing 4 to be corrected: measure the diameter of the housing 4 to be corrected with a diameter measuring tool, and mark its minimum diameter position;

[0036] S2. Install the correcting device: put the correcting device into the housing 4 to be corrected, adjust the adjusting mechanism 2, and press the pressing blocks 3 against the minimum diameter of the housing 4 to be corrected;

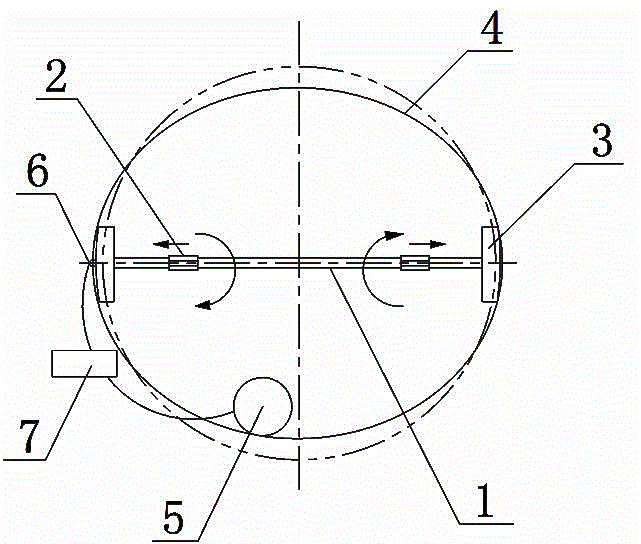

[0037] S3, afterburner support large end frame: such as figure 2 As shown, adjust the regulating mechanism 2, so that the end face diameter of the housing 4 to be corrected is enlarged by 7.5mm;

[0038] S4, vibration aging: start ...

Embodiment 3

[0042] The structure of a device for correcting the roundness of the end face of a shell product through vibration and aging is the same as that in Embodiment 1.

[0043] A method for correcting the shape of a shell product end face roundness vibration aging correction device is adopted, which comprises the following steps:

[0044] S1, measure the diameter of the housing 4 to be corrected: measure the diameter of the housing 4 to be corrected with a diameter measuring tool, and mark its minimum diameter position;

[0045] S2. Install the correcting device: put the correcting device into the housing 4 to be corrected, adjust the adjusting mechanism 2, and press the pressing blocks 3 against the minimum diameter of the housing 4 to be corrected;

[0046] S3, afterburner support large end frame: such as figure 2 As shown, adjust the adjustment mechanism 2 to make the end face diameter of the housing 4 to be corrected enlarged by 7.8mm;

[0047] S4, vibration aging: start the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com