Extracting method of placenta

An extraction method and technology of placenta, which is applied in the field of extracting placenta, can solve the problems of many technical parameter control factors, affecting the physical and chemical indicators of finished products, and being unsuitable for industrial production, so as to avoid potential safety hazards, have better taste, and save concentration time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

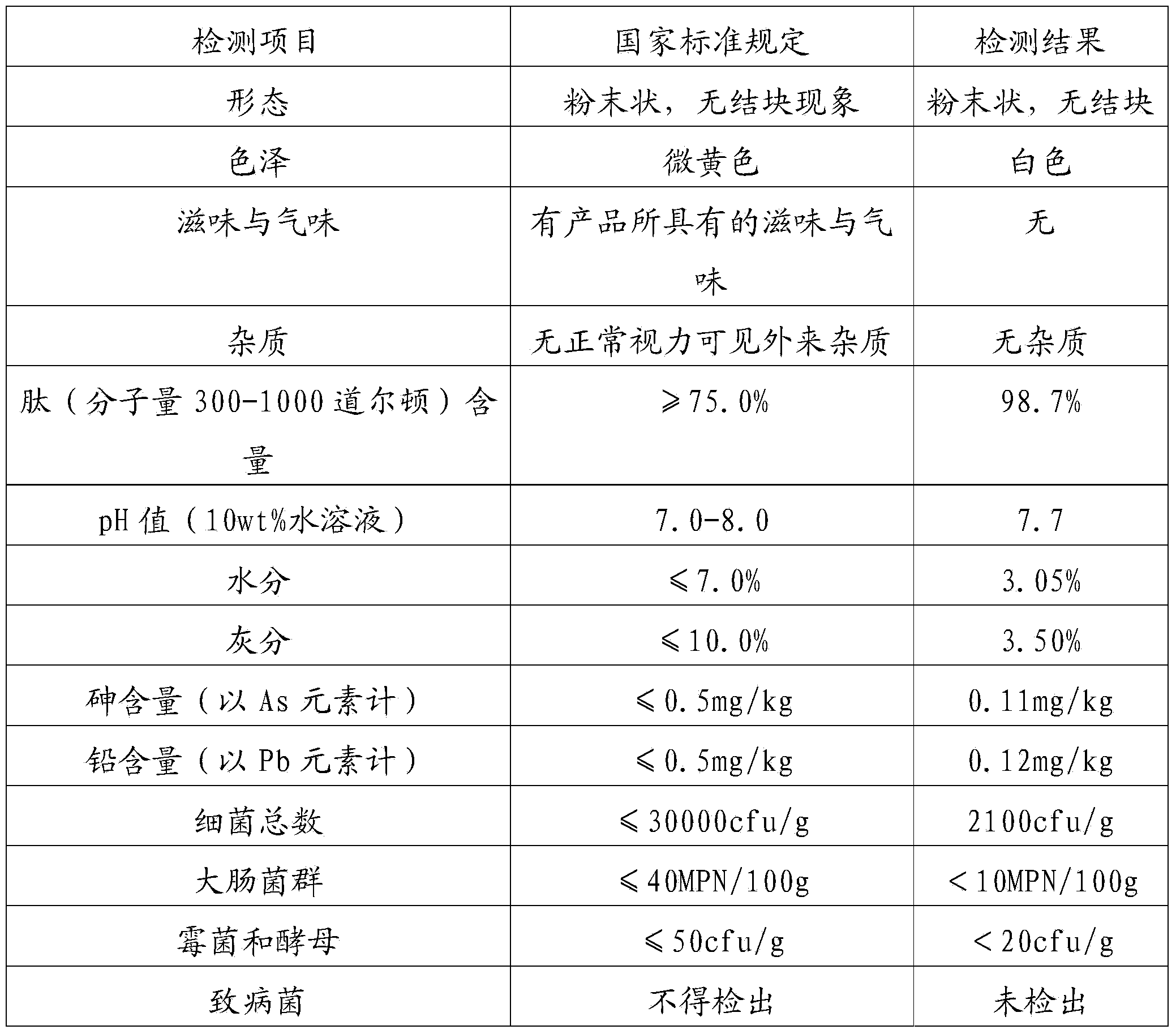

Embodiment 1

[0028] (1) Select fresh pig placenta or pig embryos qualified through inspection and quarantine, remove blood, fat and umbilical cord, wash, mince with a meat grinder as raw material, then add purified water 7 times the weight of the raw material and stir evenly, Under the condition of 95° C., cook for 35 minutes to obtain the pretreated raw material.

[0029] (2) the pretreated raw material is cooled to 52 DEG C, and the pH value is adjusted to 7.9 with food-grade sodium hydroxide, and 1.2% of the weight of the raw material is added, and the enzyme activity is 18U / mg alkaline protease, and then The temperature was kept at 52°C for 5 hours, and the pH value of the system was kept stable during the reaction. After the enzymolysis, the temperature of the obtained enzymolysis solution was raised to 92°C and kept for 15 minutes to inactivate the enzyme.

[0030] (3) Centrifuge the enzymolyzed solution after deactivating the enzyme to remove fat and solids to obtain placental fluid...

Embodiment 2

[0040] (1) Select fresh pig placenta or pig embryos qualified through inspection and quarantine, remove blood, fat and umbilical cord, wash, mince with a meat grinder as raw material, then add purified water with 8 times the weight of the raw material and stir evenly. Under the condition of 98° C., cook for 30 minutes to obtain the pretreated raw material.

[0041] (2) the pretreated raw material is cooled to 55° C., the pH value is adjusted to 8.2 with food-grade sodium hydroxide, and 2% of the raw material weight is added, and the enzyme activity is 20 U / mg alkaline protease, and then The temperature was kept at 55°C for 4 hours, and the pH value of the system was kept stable during the reaction. After the enzymolysis was completed, the temperature of the obtained enzymolysis solution was raised to 95°C and kept for 10 minutes to inactivate the enzyme.

[0042] (3) Centrifuge the enzymolyzed solution after deactivating the enzyme to remove fat and solids to obtain placental ...

Embodiment 3

[0051] (1) Select fresh pig placenta or pig embryos qualified through inspection and quarantine, remove blood, fat and umbilical cord, wash, mince with a meat grinder as raw material, then add purified water 7.5 times the weight of the raw material and stir evenly, Under the condition of 96° C., cook for 32 minutes to obtain the pretreated raw material.

[0052] (2) the pretreated raw material is cooled to 53°C, the pH value is adjusted to 8.0 with food-grade sodium hydroxide, and 1.5% of the raw material weight is added, and the enzyme activity is 22U / mg alkaline protease, and then The temperature was kept at 53°C for 4.5 hours, and the pH value of the system was kept stable during the reaction. After the enzymolysis, the temperature of the obtained enzymolysis solution was raised to 93°C and kept for 13 minutes to inactivate the enzyme.

[0053] (3) Centrifuge the enzymolyzed solution after deactivating the enzyme to remove fat and solids to obtain placental fluid.

[0054]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com