Liquid-state re-distilling device for pure-grain solid-state fermented liquor by electromagnetic induction heating

An electromagnetic induction heating and solid-state fermentation technology, which is applied in the field of liquor distillation, can solve problems such as difficult application, high cost, and low efficiency, and achieve the effect of improving the quality of new liquor and quickly separating it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

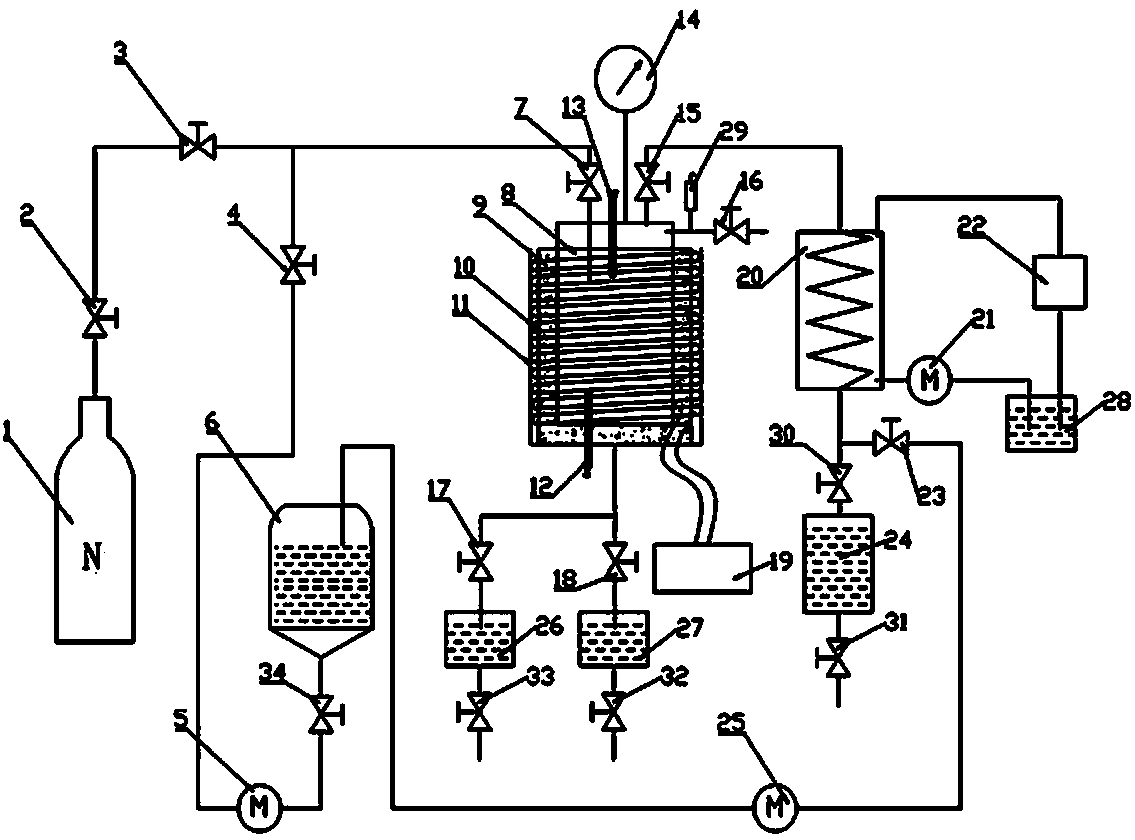

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Electromagnetic induction heating pure grain solid-state fermented liquor liquid re-distillation device, including still body and heating system, wine liquid fraction cooling system, wine liquid and nitrogen supply system, all systems are connected by pipelines, control valves, and material pumps. form a loop.

[0017] Still heating system: the upper part of the still body 8 is equipped with a pressure gauge 14, a safety valve 29, an emptying valve 16, a thermometer II 13, the upper part of the still body 8 is connected to the still inlet valve 7, and the condenser is connected to the pipe and valve 15 20; the lower part of the distillation kettle body 8 is equipped with a thermometer I12; the distillation kettle body 8 is covered with an insulation layer 9, and the insulation layer is equipped with an electromagnetic induction coil 10 and an electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com