Deep curable and highly transparent condensation-type silicone potting glue, preparation method and application thereof

A deep curing and condensation-type technology, applied in the direction of chemical instruments and methods, non-polymer adhesive additives, adhesives, etc., can solve the problems of limited application, influence, poor performance, etc., and achieve convenient operation, simple production process, Excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. In this embodiment, a highly transparent condensation-type silicone encapsulant that can be deeply cured is formed by mixing component A and component B; the raw material compositions of component A and component B are as follows in parts by weight:

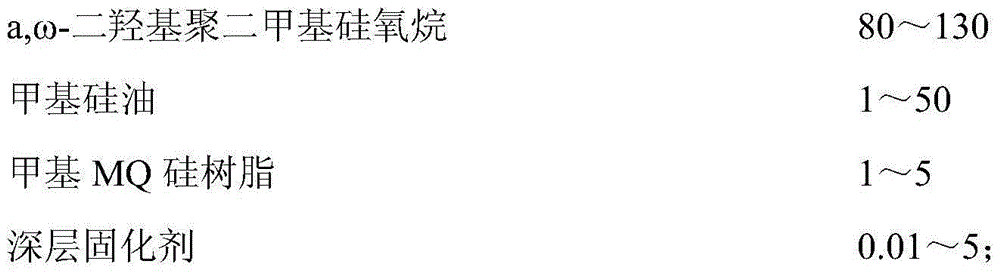

[0026] Component A:

[0027]

[0028] Component B:

[0029]

[0030] *The deep curing agent amphiphilic emulsion is octadecyl dihydroxyethyl amine oxide;

[0031] **The coupling agent is: a mixture of γ-aminopropyltriethoxysilane:Y-(2,3-glycidoxy)propyltrimethoxysilane=1:3 by weight.

[0032] 2. The preparation method of a highly transparent condensation-type silicone potting compound capable of deep curing in this embodiment is as follows:

[0033] Preparation of component A:

[0034] Stir and mix the raw materials of the above-mentioned component A for 20 minutes at normal pressure with a stirring speed of 25 Hz and a dispersion speed of 25 Hz to obtain component A;

[0035] Preparation of component B:

[0...

Embodiment 2

[0038] 1. In this embodiment, a highly transparent condensation-type silicone encapsulant that can be deeply cured is formed by mixing component A and component B; the raw material compositions of component A and component B are as follows in parts by weight:

[0039] Component A:

[0040]

[0041]

[0042] Component B:

[0043]

[0044] 2. The preparation method of a highly transparent condensation-type silicone potting compound capable of deep curing in this embodiment is as follows:

[0045] Preparation of component A:

[0046] Stir and mix the raw materials of the above-mentioned component A for 25 minutes at normal pressure with a stirring speed of 5 Hz and a dispersion speed of 15 Hz to obtain component A;

[0047] Preparation of component B:

[0048] Stir and mix the raw materials of the above-mentioned component B under nitrogen protection for 10 minutes to obtain the component B.

Embodiment 3

[0050] 1. In this embodiment, a highly transparent condensation-type silicone encapsulant that can be deeply cured is formed by mixing component A and component B; the raw material compositions of component A and component B are as follows in parts by weight:

[0051] Component A:

[0052]

[0053] Component B:

[0054]

[0055] 2. The preparation method of a highly transparent condensation-type silicone potting compound capable of deep curing in this embodiment is as follows:

[0056] Preparation of component A:

[0057] Stir and mix the raw materials of the above-mentioned component A for 25 minutes at normal pressure with a stirring speed of 2 Hz and a dispersion speed of 35 Hz to obtain component A;

[0058] Preparation of component B:

[0059] Stir and mix the raw materials of the above-mentioned component B under nitrogen protection for 15 minutes to obtain the component B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com