A kind of preparation method and application of special wax

A technology of special wax and paraffin wax, which is applied in ink and metal anti-rust industry, daily chemical industry, and special wax preparation field, which can solve the problems of complex ingredients and achieve reduced production costs, good corporate and social benefits, and market competitiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0036] Adopt respectively the material proportion shown in Table 2, prepare special wax of the present invention with above-mentioned method.

[0037] Table 2: Material proportion (%) of embodiment 1-9

[0038]

[0039] Known from above-mentioned embodiment and comparative example, adopt the microcrystalline wax of 72-74%, the paraffin wax of 14-15%, the polyethylene wax of 5-5.5%, the beeswax of 4-5%, the castor wax of 3-3.5% , Through the reverse processing method of the present invention, the special wax of the present invention can be obtained, and its penetration, drop melting point, viscosity, oil content and color can all reach the performance index requirements described in Table 1.

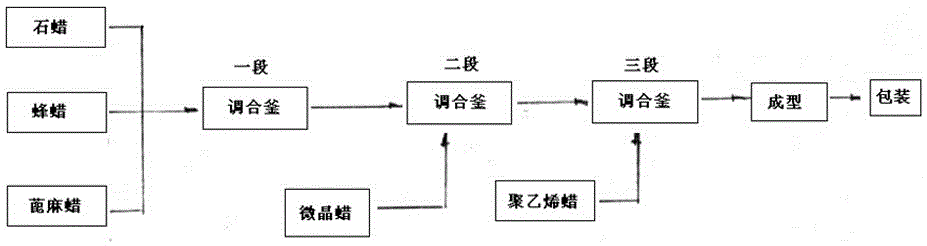

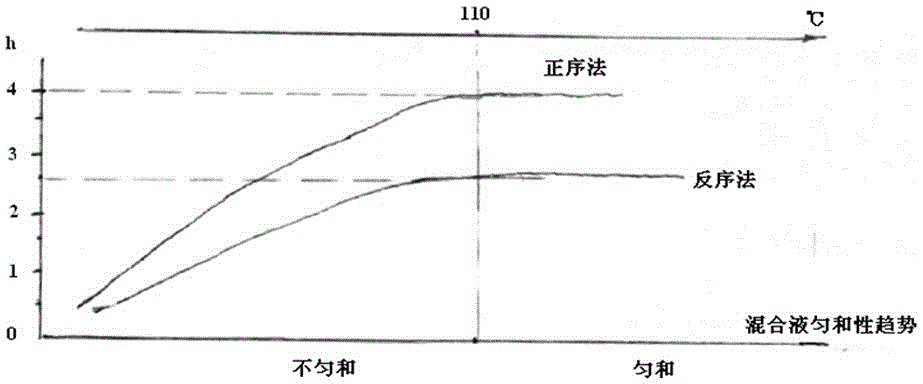

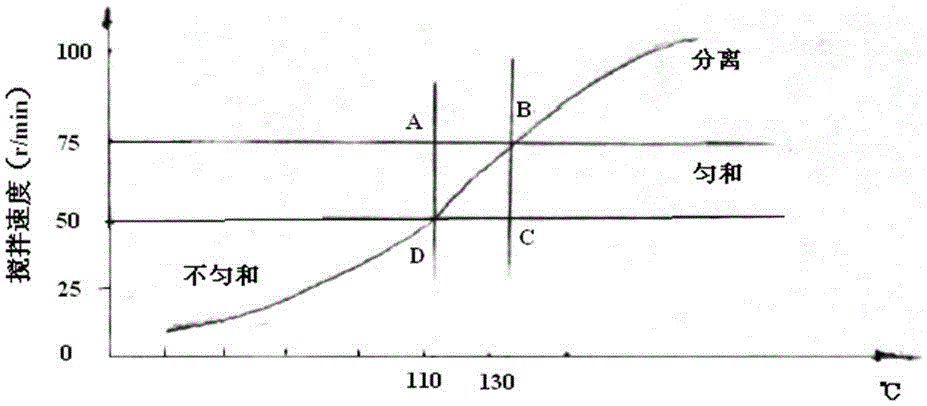

[0040] The invention adopts the reverse sequence processing method and the three-stage reaction process of increasing the temperature gradually, which is the first creation of special wax production. Controlling the melting point of the special wax by this method can shorten the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com