Hydraulic feeding numerical control press

A CNC punching and feeding technology, which is applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of high punching processing cost of large workpieces, positioning or feeding device punching, etc., to solve the processing of positioning and feeding. Problems, low cost, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

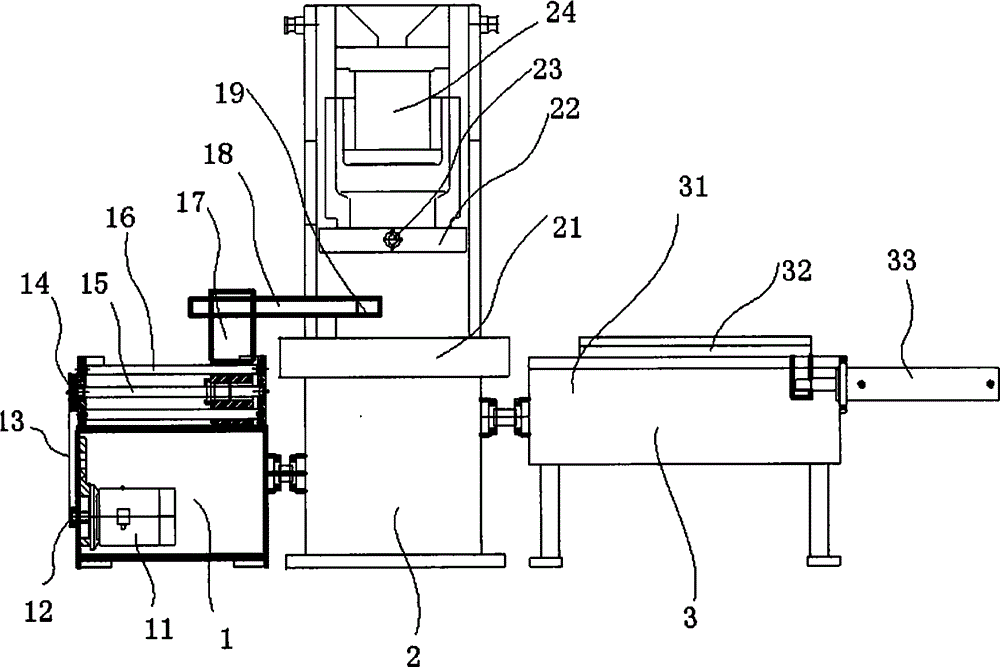

[0034] Such as figure 1 As shown, a hydraulic feeding CNC punch press of this embodiment includes a positioning part 1 and a blanking part 2, and also includes a hydraulic feeding part 3; The left and right ends are fixedly connected respectively.

[0035] The blanking part 2 includes a workbench 21 , a slider 22 , a punching die 23 and a press 24 . The workbench 21 is located in the middle of the blanking part 2 . The slide block 22 , the punching die 23 and the press machine 24 form a whole and are vertically fixed above the workbench 21 with a bracket; the slide block 22 is fixed at the lower end of the press machine 24 . The punching die 23 is fixed on the lower surface of the middle part of the slider 22 ; the hydraulic feeding part 3 includes a feeding frame 31 , a feeding slider 32 and a feeding cylinder 33 . The feeding slider 32 is located on the upper surface of the feeding frame 31; the feeding cylinder 33 is fixed on the right side of the feeding frame 31; the f...

Embodiment 2

[0044] A kind of hydraulic feeding CNC punching machine of this embodiment, its basic structure is the same as that of Embodiment 1, the difference is that: there are 4 punches on the punching die 23; the right end of the retaining finger 18 is higher than the Workbench 21 upper surface 3cm.

[0045] A kind of hydraulic feed numerical control punching machine of this embodiment, its concrete processing process to the I-beam is the same as embodiment 1, the difference is: this embodiment is suitable for processing the I-beam with higher height, and the press 24 drives the punching die 23 vertical drops can punch down 4 holes of every row of the I-beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com