Single-substrate integrated terahertz front end

A terahertz, single-substrate technology, applied in the terahertz front-end field, can solve problems such as insufficient integration and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

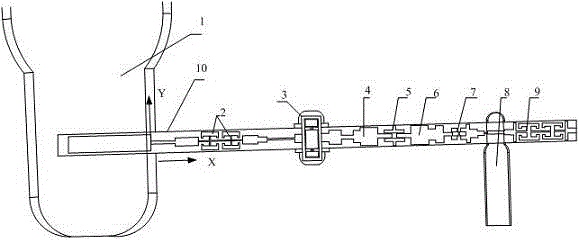

[0046] Such as Figure 1 to Figure 10 shown.

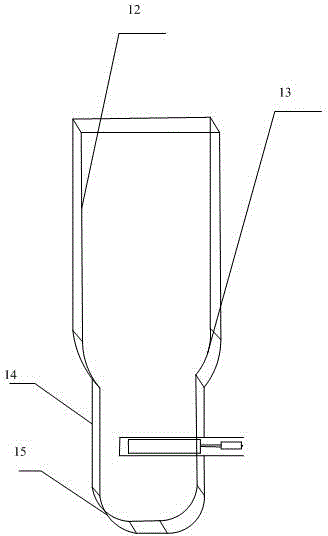

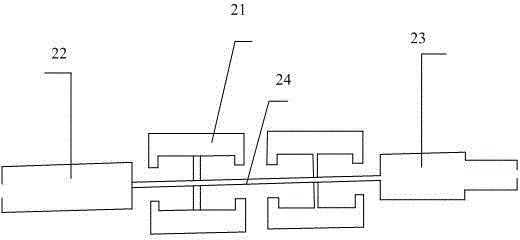

[0047] A single-substrate integrated terahertz front-end, including a dielectric substrate 10 arranged in an air cavity 11, in the direction from left to right (as shown in the figure, along the X-axis direction), the dielectric substrate 10 is provided with microstrips passing sequentially Line-connected CMRC structure microstrip low-pass filter 2, parallel double frequency diode 3, frequency doubling matching stub 4, local oscillator band-pass filter 5, mixing matching stub 6, mixing diode 7, intermediate frequency low-pass filter 9. It also includes an input waveguide microstrip transition 1. A transition microstrip line is also provided on the dielectric substrate 10. The transition microstrip line is connected to the CMRC structure microstrip low-pass filter 2 through the input microstrip line A22. The transition microstrip line is located Both the air cavity 11 and the dielectric substrate 10 in the area extend into the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com