12-pulse-wave self-coupling phase shift rectifier transformer

A technology for rectifying transformers and transformers, applied in the direction of transformer/inductor coil/winding/connection, etc., which can solve problems such as large weight and volume, and bottlenecks in rectifier cabinet design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

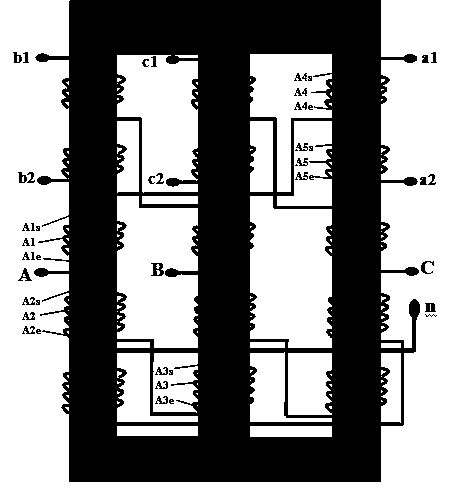

[0034]A 12-pulse self-coupling phase-shifting rectifier transformer, including a transformer frame and windings, the transformer frame includes three iron core columns, the windings include A-phase windings, B-phase windings and C-phase windings; the A-phase windings include a first part Winding A1, second part winding A2, third part winding A3, fourth part winding A4 and fifth part winding A5; B-phase winding includes first part winding B1, second part winding B2, third part winding B3, fourth part winding The partial winding B4 and the fifth partial winding B5; the C-phase winding includes the first partial winding C1, the second partial winding C2, the third partial winding C3, the fourth partial winding C4 and the fifth partial winding C5; it is characterized in that: the transformer The three-phase windings are respectively wound on three iron core columns, among which,

[0035] The first part of the winding A1 and the second part of the winding A2 of the phase A winding ...

Embodiment 2

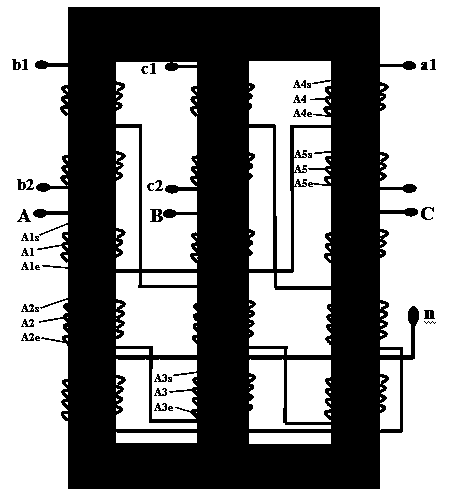

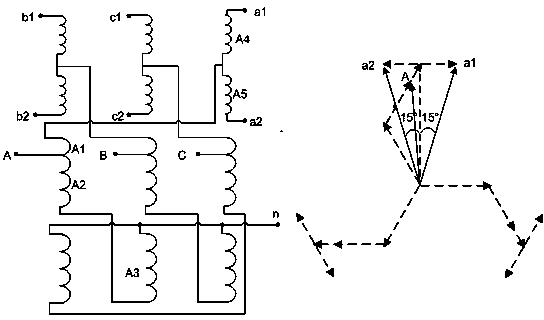

[0050] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the transformation ratio of the input phase voltage on the primary side of the transformer and the output phase voltage on the secondary side is greater than or equal to cos(15°). At this time,

[0051] The end A1e of the first partial winding A1 of the A-phase winding, the first end A2s of the second partial winding A2, the end A4e of the fourth partial winding A4, and the first end A5s of the fifth partial winding A5 are connected, and the end A2e of the second partial winding A2 of the A-phase winding Connected to the end A3e of the third partial winding A3;

[0052] The end A5e of the fifth partial winding A5 of the A-phase winding is used as the second output terminal a2 of the A-phase winding, the first terminal A1s of the first partial winding A1 is used as the input terminal of the A-phase winding, and the first terminal A4s of the fourth partial winding A4 is used as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com