Aviation fluorine-containing polymer insulated wire and cable surface laser character printing method

A technology for insulating wires and polymers, applied in the direction of marking conductors/cables, etc., can solve the problems of failing to meet the requirements of the firmness of the printed logo, poor firmness of the printing, and high risk, so that the fonts are firm and not easy to change color, and the work efficiency is improved. , the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

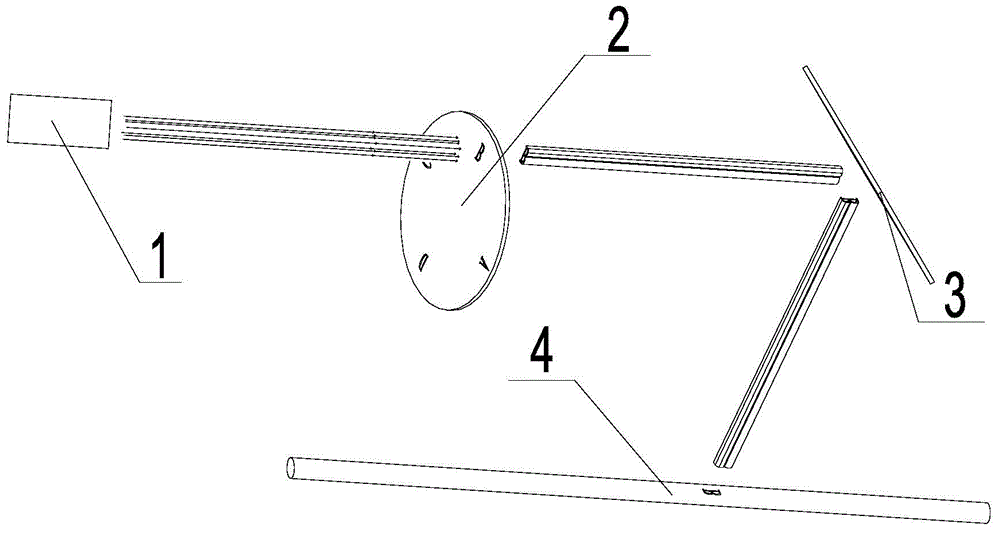

[0017] A method for laser printing on the surface of an aviation fluoropolymer insulated wire and cable, the method comprising the following steps:

[0018] 1) An excimer laser generator is used, the beam is converged by a quartz lens, and an excimer laser is generated by adjusting the excitation voltage of the excimer laser generator.

[0019] 2) Pass the excimer laser through a font to form a letter-shaped laser.

[0020] 3) The letter-shaped laser irradiates the surface of the fluoroplastic insulated wire, and the surface layer of titanium dioxide molecules in the fluoroplastic irradiated by the laser rapidly heats up and melts and condenses and solidifies rapidly. During the rapid melting and re-solidification process, after discoloration occurs, the cable is wound up.

[0021] The speed of the aviation fluorine-containing polymer insulated wire and cable under the laser is 10 meters to 20 meters per minute.

[0022] The excimer laser generator is filled with XeCL gas, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com