Electronic skin based on three-dimensional flexible substrate graphene and preparing method thereof

An electronic skin and three-dimensional flexible technology, applied in the field of sensors, can solve problems such as complex manufacturing process, low sensitivity and signal strength, and human toxicity, and achieve the effect of using health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

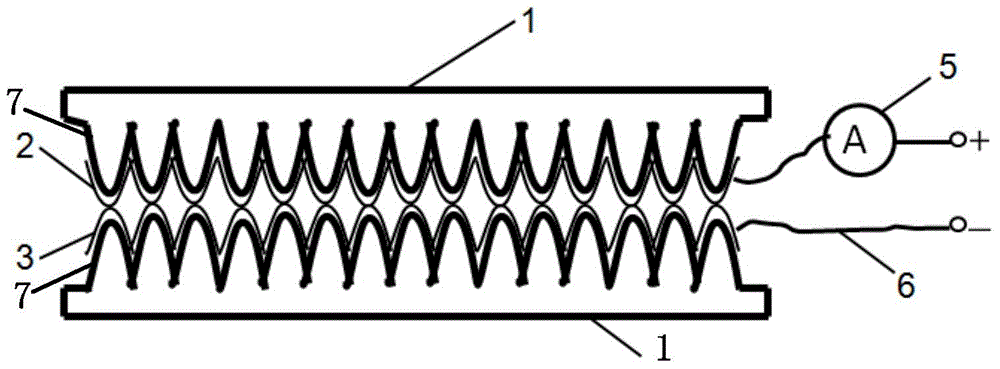

[0043] (1) Using methane as the carbon source gas, hydrogen as the carrier gas, and Cu foil as the growth substrate, graphene films were grown in a high-temperature tube furnace. The growth temperature is 1000°C, the air pressure is maintained at about 1×103Pa, and the growth time is 20 minutes to grow a single-layer graphene film.

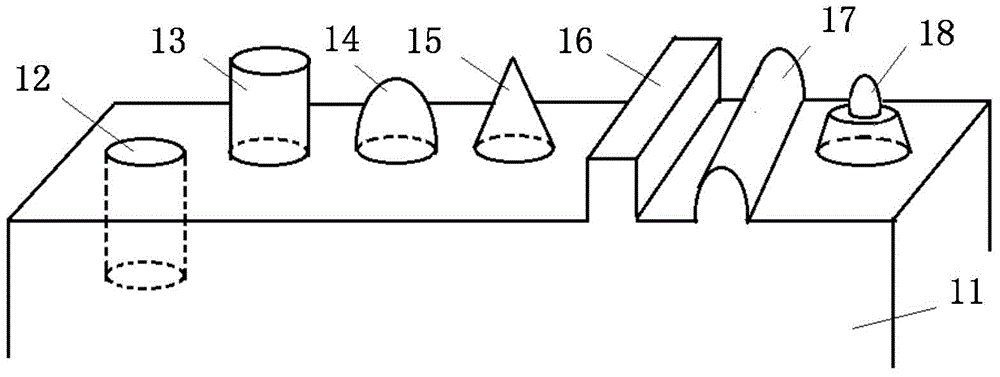

[0044] (2) A flexible PDMS substrate with a three-dimensional surface structure is produced by molding equipment. The surface structure is a curved surface convex array structure with a structure size of about 100 microns, and the copper foil with graphene grown on it is pressed on the flexible PDMS substrate. Together, the Cu foil was removed by FeCl3 solution etching, and the graphene was transferred to the three-dimensional flexible PDMS surface; finally, it was placed on a hot plate at 80°C for 20 minutes to remove water vapor and make the graphene closely adhere to the PDMS surface.

[0045] (3) Electrodes will be made by printing with silver...

Embodiment 2

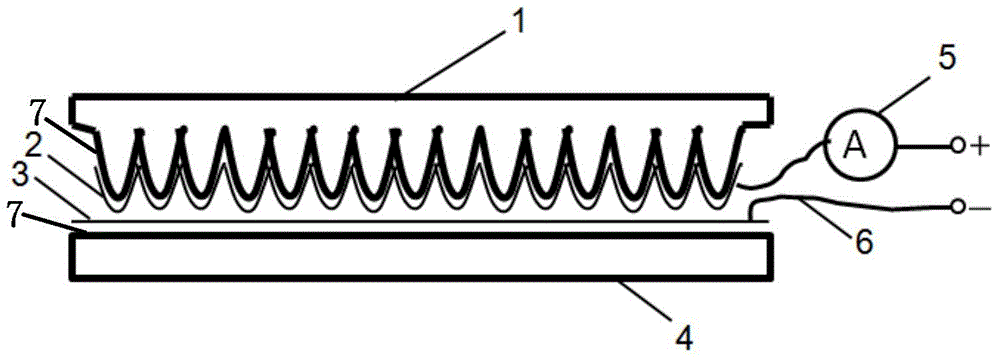

[0049] (1) Using methane as the carbon source gas, hydrogen as the carrier gas, and Ni foil as the growth substrate, a graphene film was grown in a high-temperature tube furnace. The growth temperature is 950°C, the air pressure is maintained at about 1×103Pa, and the growth time is 30 minutes to grow a graphene film with multiple layers of carbon atoms.

[0050] (2) The specific method of transferring graphene on the PET film surface with a flat surface is: attaching thermal release tape on the surface of graphene / Ni substrate, removing the Ni foil in the Ni etching solution, and transferring the graphene to the heat Release the surface of the tape, then attach it to the PET surface, heat at 110° C. for 5 minutes, the thermal release tape is detached, and the graphene is transferred to the surface of the PET film.

[0051] (3) The steps of making a PDMS substrate with a three-dimensional surface structure and transferring graphene are as follows: a flexible PDMS substrate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com