A vertical cement clinker cooler

A cement clinker cooling and vertical technology, which is applied in clinker production, cement production, and treatment of discharged materials, etc., to achieve the effects of sufficient heat exchange, low investment, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

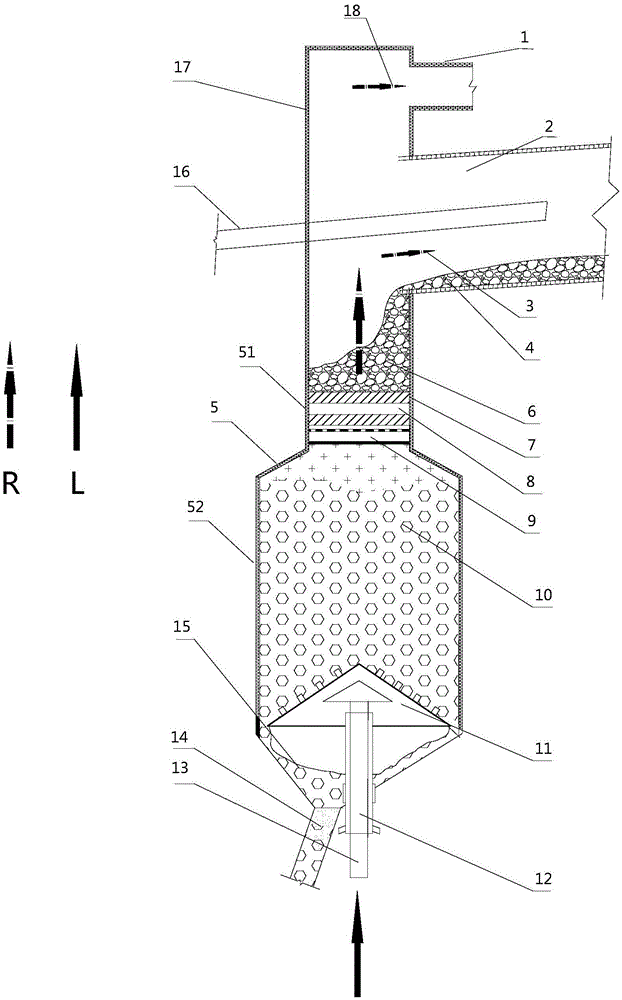

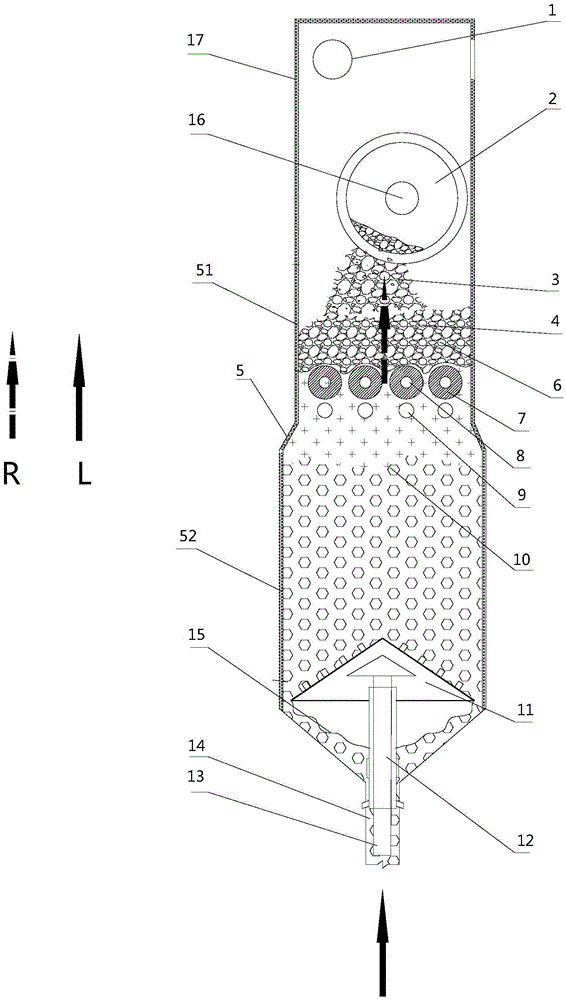

[0019] like figure 1 and figure 2 As shown, the present invention is a vertical cement clinker cooler, including a cylinder body 5, the cylinder body 5 is composed of an upper vertical cylinder 51 and a lower vertical cylinder 52 sealed and connected, and the top of the upper vertical cylinder 51 is connected to the feed port 2, namely In the rotary kiln of a cement plant, the upper vertical cylinder 51 is also connected to the kiln head cover 17, the upper vertical cylinder 51 is equipped with a crusher 7, the space above the crusher 7 is the quenching zone 6, and the lower vertical cylinder 52 is equipped with a discharge machine 11. There is a discharge pipe 14 at the bottom of the lower vertical tube 52, and the space between the discharge machine 11 and the crusher 7 is a cooling zone 10. The discharge machine 11 is driven by a transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com