Solid heat storage method

A heat method and heat storage technology, which can be applied to heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as waste of energy utilization, and achieve the effects of enhanced heat exchange effect, high cost performance, and flexible heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

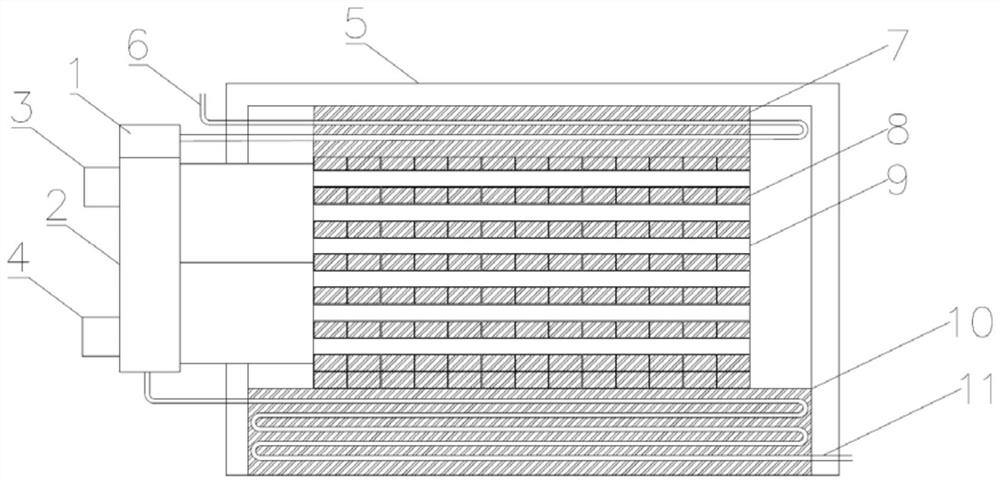

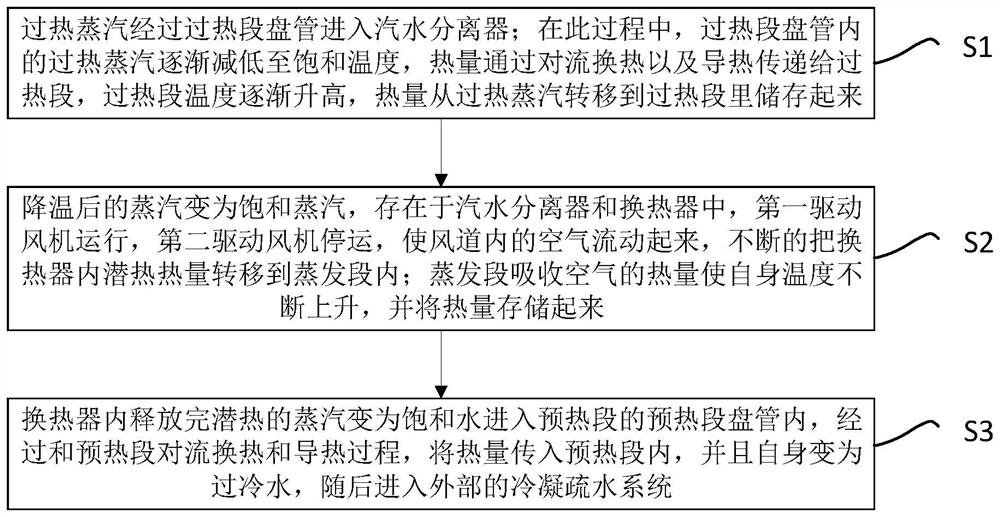

[0041] like image 3 and 4 As shown, the embodiment of the present invention provides a solid heat thermal storage method, comprising the following steps:

[0042] S1: The superheated steam enters the steam-water separator 1 through the superheated section coil 6; during this process, the superheated steam in the superheated section coil 6 is gradually reduced to the saturation temperature, and the heat is transferred to the refractory of the superheated section 7 through convection heat transfer and heat conduction Bricks, the temperature of the refractory bricks in the superheating section 7 is gradually increased, and the heat is transferred from the superheated steam to the refractory bricks in the superheating section 7 and stored;

[0043] S2: The steam after cooling becomes saturated steam, which exists in the steam-water separator 1 and the heat exchanger 2. The first driving fan 3 is running, and the second driving fan 4 is stopped, so that the air in the air duct 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com