Anti-abrasion elbow

A wear-resistant and elbow technology, which is applied in the direction of elbows, pipelines to prevent damage/abrasion, pipes/pipe joints/fittings, etc. It can solve the impact at the corner of the pipeline, the wear of the end of the pipe at both ends, and the unsatisfactory service life, etc. problem, to achieve the effect of prolonging service life, easy replacement and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific implementation plan

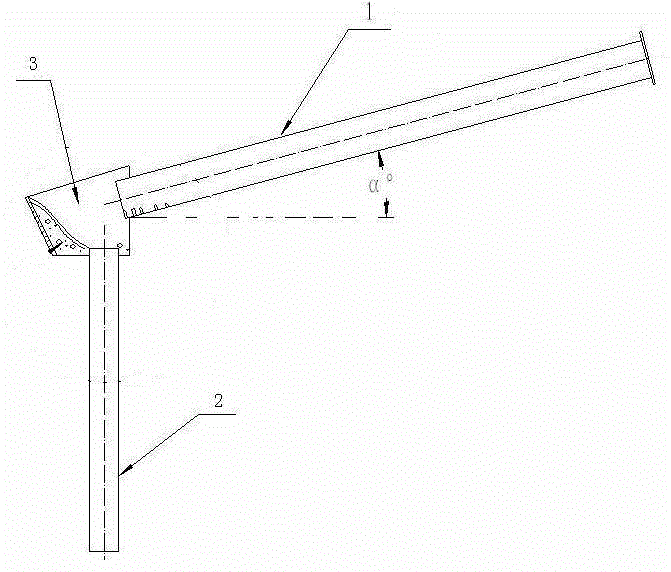

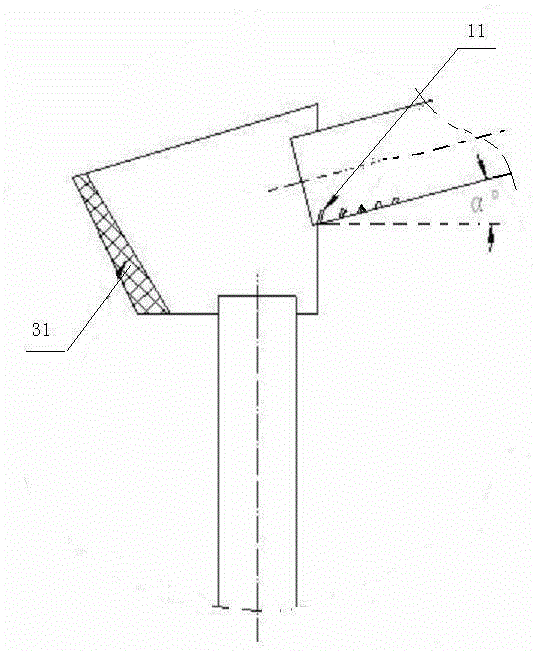

[0015] From figure 1 , figure 2 It can be seen that a wear-resistant elbow of the present invention includes a straight feed pipe 1, a box body 3, and a straight discharge pipe 2. The straight feed pipe 1, the box body 3, and the straight discharge pipe 2 respectively It is made of bimetal composite wear-resistant steel plate, and the end of the flow surface of the feed straight pipe 1 and the impact surface of the box 3 are also welded with wear-resistant ribs 11 and 31 respectively. The straight feeding pipe 1, the box body 3, and the straight outlet pipe 3 of the split structure are welded and combined into an integral structure elbow.

[0016] The three parts of the wear-resistant elbow of the present invention are separately manufactured, and when one part is damaged, it is convenient to replace. The box body 3 changes the flow direction of materials in the wear-resistant feeding straight pipe 1 and the discharging straight pipe 2, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com