Energy recovery and utilization system for movable arm potential energy

A technology of energy recovery and boom potential energy, which is applied to fluid pressure actuation system components, fluid pressure actuation devices, mechanically driven excavators/dredgers, etc., can solve the problem of no overload protection function and boom potential energy recovery efficiency Reduced, complex system structure and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

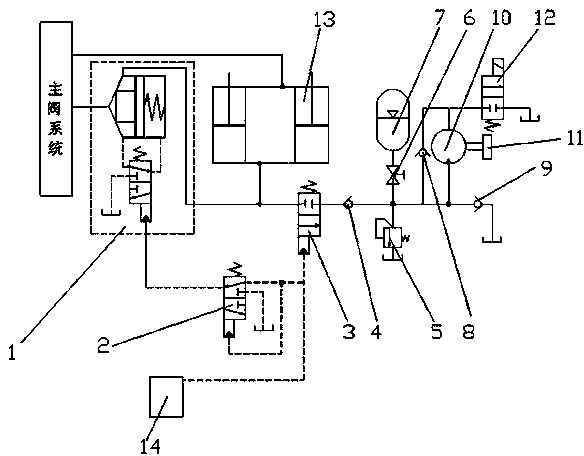

[0026] The invention will be further described below in conjunction with the accompanying drawings.

[0027] like figure 1 As shown, a boom potential energy recovery and utilization system includes a boom cylinder 13, an accumulator 7, a main valve system, a boom lock valve 1, a first hydraulic control reversing valve 2, a second hydraulic control reversing valve Valve 3, the rod cavity oil port of the boom cylinder 13 and the oil inlet of the boom lock valve 1 are connected to the working joint pipeline of the main valve system, and the oil outlet of the boom lock valve 1 port, the rodless chamber oil port of the boom cylinder 13, and the oil inlet port of the second hydraulic control reversing valve 3 communicate with each other through pipelines, and the control oil port of the boom lock valve 1 is connected to the first hydraulic control reversing valve. The oil outlet of the valve 2 is connected to the pipeline, and the oil inlet of the first hydraulic control reversing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com